An X-ray pinhole camera and its installation and adjustment method for strong laser conditions

A pinhole camera and X-ray technology, applied in optics, instruments, photography, etc., can solve problems such as the failure of X-ray pinhole cameras, and achieve the effect of saving adjustment time, increasing accuracy, and simplifying adjustment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

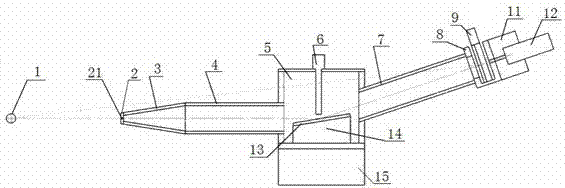

[0034] Such as image 3 , Figure 4 and Figure 5 As shown, this embodiment is used for an X-ray pinhole camera under strong laser conditions, and the pinhole camera includes a pinhole plate 2, a pinhole seat housing 3, a front light tube 4, a grazing incidence mirror chamber, and a rear light tube 7. Film chamber 8, film cassette 9, filter frame 10, filter disc 10-1, negative film 10-2, two-dimensional adjustment laser seat 11, semiconductor laser 12 and two-dimensional adjustment frame 15, in the film chamber 8 A two-dimensional adjustment laser seat 11 is fixedly arranged on the outside, and a semiconductor laser 12 is installed on the side corresponding to the film chamber 8 on the two-dimensional adjustment laser seat 11. A through hole for adjusting the passage of the laser light; the grazing incidence mirror chamber includes a mirror chamber housing 5, a light blocking lead plate 6, a grazing incidence mirror 13 and a two-dimensional adjustment grazing incidence mirro...

Embodiment 2

[0047] Such as image 3 , Figure 4 and Figure 5 As shown, the present embodiment is used for an X-ray pinhole camera under strong laser conditions. In order to realize high-temperature plasma X-ray imaging under strong laser irradiation and high background noise conditions, the pinhole camera includes a pinhole plate 2, a pinhole Housing housing 3, front light tube 4, grazing incidence mirror room, rear light tube 7, film chamber 8, film box 9, filter frame 10, filter 10-1, film 10-2, two-dimensional adjustment laser Seat 11, semiconductor laser 12 and two-dimensional adjustment frame 15, two-dimensional adjustment laser seat 11 is fixedly arranged on the outside of described film chamber 8, semiconductor laser is installed on the side corresponding to film chamber 8 on two-dimensional adjustment laser seat 11 12. At the optical axis positions of the two-dimensional adjustment laser seat 11 and the film chamber 8, there are through holes for the adjustment laser to pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com