Processing technology and clamping device of curvature radius template of outer spherical surface ball bearing

A technology of curvature radius and clamping device, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems that the upper and lower limit curvature samples cannot be made together, and it is difficult to process the dimensional accuracy of the curvature radius, etc., to achieve Guaranteed good rate, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

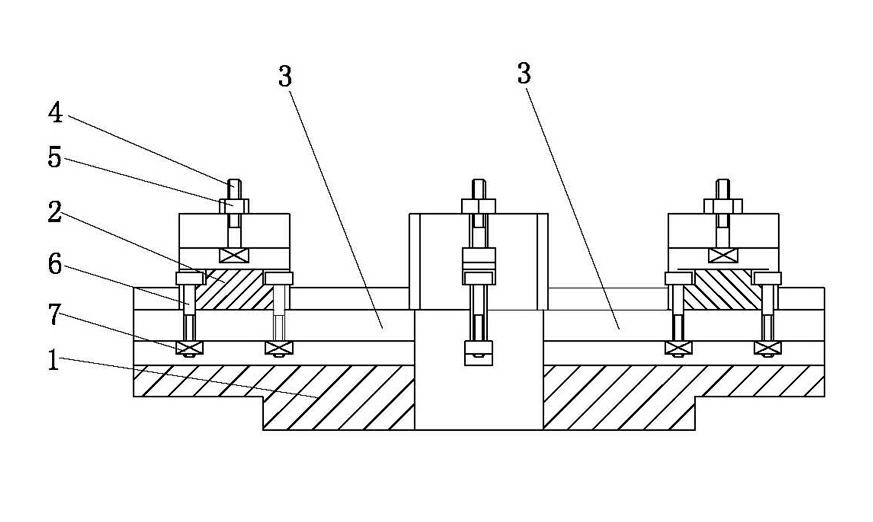

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

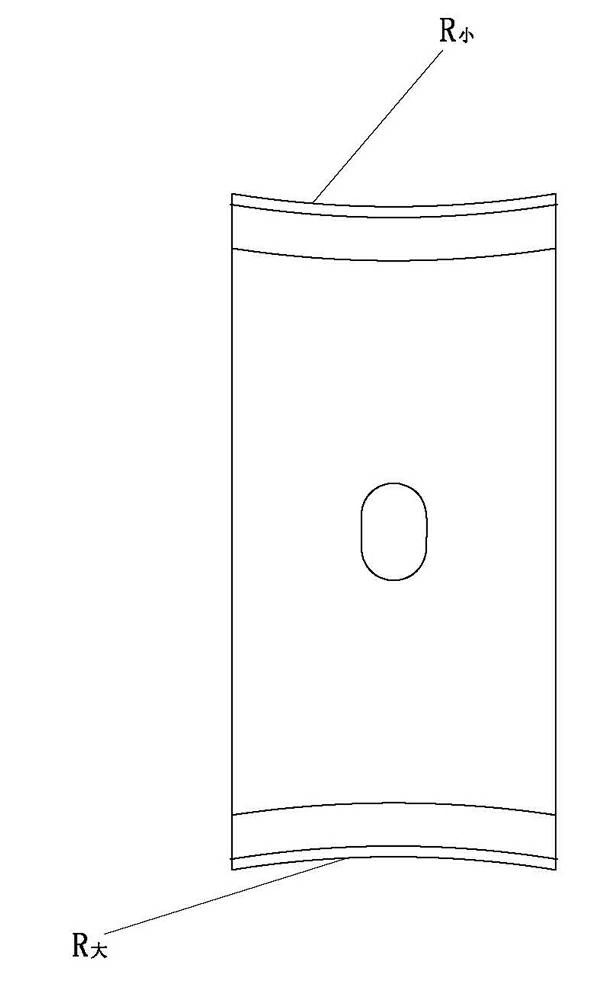

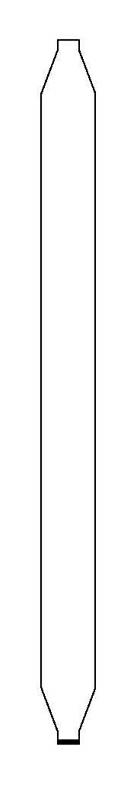

[0024] as attached figure 1 , 2 As shown, the present invention discloses a processing technology for a radius of curvature template of an outer spherical ball bearing. 1) Carry out longitudinal and transverse forging on the blank until the thickness of the blank is 6.5-7mm. The blank is preferably high-carbon chromium bearing steel, Of course, this list is not limited, and other materials can also be used;

[0025] 2) Spheroidizing annealing, the hardness of spheroidizing annealing is Brinell hardness HBS190-210, which can be specifically Brinell hardness HBS190, or Brinell hardness HBS200, or Brinell hardness HBS210.

[0026] 3) Milling, put the blank after spheroidizing and annealing on the milling machine for milling into a sample, mill the thickness of the sample to 5.35-5.45mm, and process it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com