Method for measuring radius of curvature of spherical surface

A technology of radius of curvature and spherical surface to be measured, applied in measurement devices, instruments, optical devices, etc., can solve the problems of complex spherical curvature radius detection methods, low detection cost, inability to detect multi-layer spherical curvature radius, etc., and achieve an important technology Value and economic value, reduced production process, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

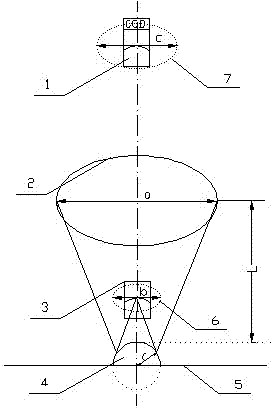

[0025] Detect the radius of curvature of a small droplet. Such as figure 1 , the size of the droplet is on the order of mm, and the ring light source is reflected by the surface of the droplet to form a reduced image, which is enlarged by the microscopic system, and then captured by the CCD camera as a picture and sent to the computer for storage through the data line. According to the above formulas (2) and (3), we can get , substituting into formula (1) to get . If the small water drop in the air environment on the plane is regarded as a lens, the focal length of the liquid lens can be calculated as: .

Embodiment 2

[0027] Detects the focal length of the liquid lens. Such as figure 2 , is a schematic diagram of the structure of a two-liquid lens. In the figure, the meniscus-shaped contact surface of two immiscible liquids, oil and water, is a liquid lens. There are two planes and one curved surface in the figure. When using this method to measure the radius of curvature of the curved surface, the standard object will form three images through the three surfaces, but the imaging size of the curved surface is small. Use a microscope system with a slightly larger objective lens to observe and record , which can effectively exclude the other two images from the field of view. This case can be used for real-time dynamic measurement of focal length, for example, the voltage-applied zoom curve of a liquid zoom lens based on the electrowetting effect can be measured. At this time, since the refractive index of oil and water are relatively close, the reflected light is not obvious, and a ring-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com