Method for highly precisely eliminating adjustment error in spherical surface shape interference detection

A technology for interference detection and error adjustment, applied to measuring devices, instruments, optical devices, etc., can solve problems such as defocus errors that have not yet been removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

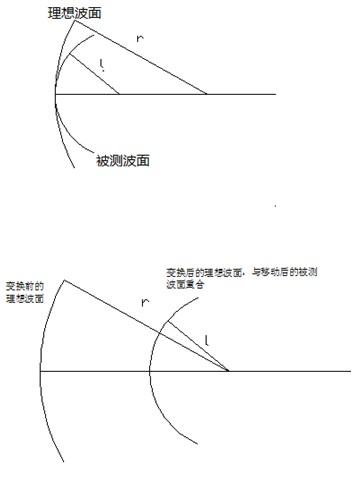

Problems solved by technology

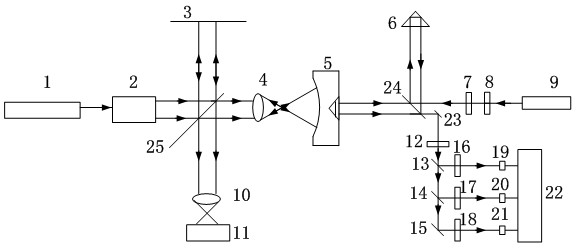

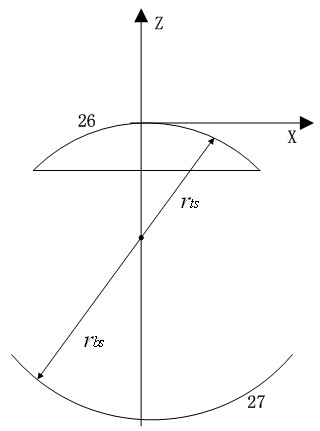

Method used

Image

Examples

Embodiment 1

[0073] Detect the surface shape of the caliber φ=37mm radius of curvature R=25mm spherical mirror, and process the detection result with the inventive method to obtain the final surface shape process as follows:

[0074] 1) The number of pulses generated by moving from the center of the sphere to the apex of the sphere measured by single-frequency laser interferometry is 317573 (the wavelength of the laser used is 632.8nm), so .

[0075] 2) Use the GPI interferometer of Zygo Company to measure the surface shape data of the tested spherical surface , the laser wavelength used by the interferometer .

[0076] 3) Transform the surface shape data into the global coordinate system, and calculate the pose transformation matrix by the least square method and ideal face radius change .

[0077]

[0078]

[0079] 4) Calculate the surface shape value after defocusing according to step 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com