Narrow and long type free-form surface part machining track self-adaptive generation method

A technology for processing trajectory and curved surface parts, which is applied in the direction of instruments, digital control, control/adjustment systems, etc., can solve problems such as unsmooth tool tracks, unreasonable gaps between adjacent tool tracks, and irregular long-side boundaries, etc., to improve processing Accuracy and efficiency, the effect of enhancing the potential of CNC machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

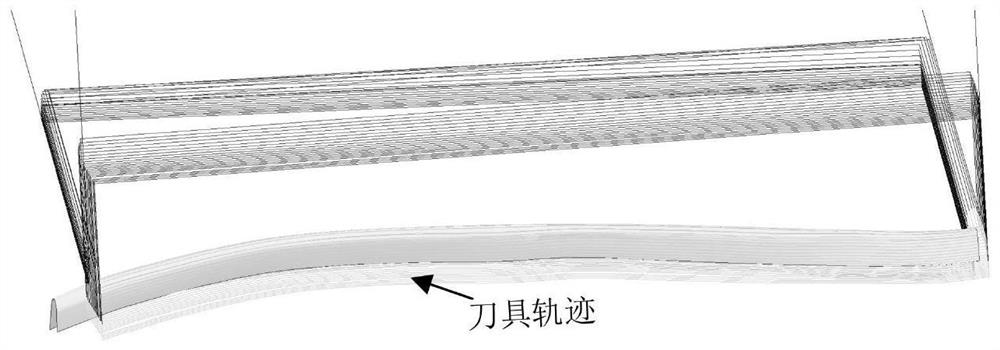

[0061] The size of a narrow and long free-form surface is about 51.5×1.3mm, and the contour tolerance of the drawing design is [-0.03mm~+0.05mm]. The cutter used is a ball-end cutter with R=1.5mm. The specific implementation process is as follows.

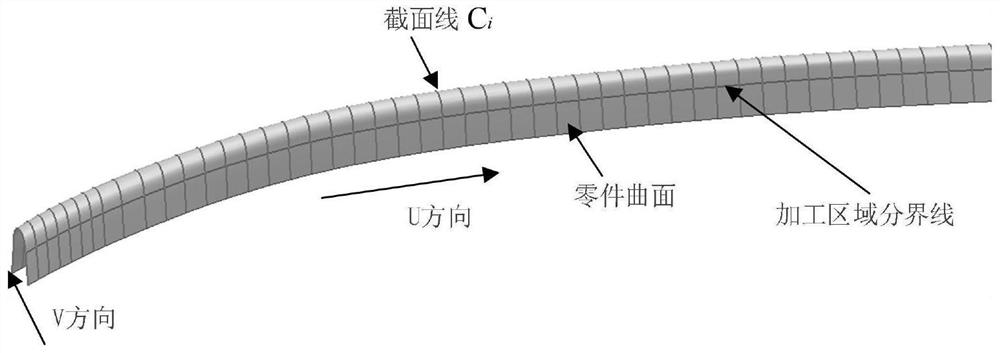

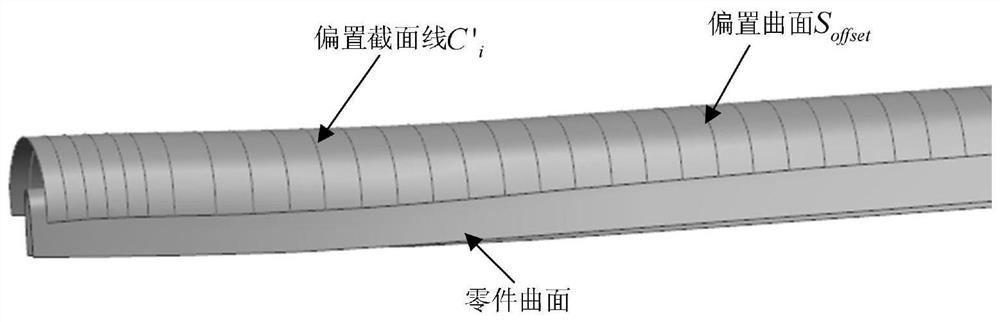

[0062] Step 11: Set the length direction of the free-form surface of the part to the U direction, the width direction to the V direction, and construct the U-height section line group {B of the free-form surface of the part 0 ,B 1 ,...B i ...B 60}.

[0063] Step 12: Use the curve lofting method to set the equal U-height section line group {B 0 ,B 1 ,...B i ...B 60} Stake out to regenerate the surface S, and analyze the deviation from the predetermined surface. The result shows that the average deviation is 0.006mm, which is less than the tolerance of the drawing, so {C 0 ,C 1 ,...C i ...C 60} is {B 0 ,B 1 ,...B i ...B 60}.

[0064] Step 23: Calculate {C 0 ,C 1 ,...C i ...C 60}The section line arc length value and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com