Suspension polyvinyl chloride polymerization section wastewater treatment method and device

A polyvinyl chloride and wastewater treatment technology, applied in water/sewage treatment, natural water treatment, biological water/sewage treatment, etc., can solve the problems of substandard wastewater treatment and high energy consumption for treatment, and achieve rapid and effective removal and mass transfer The effect of high efficiency and high processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below through a specific embodiment and in conjunction with the accompanying drawings. The same reference numerals in the drawings represent the same and similar parts.

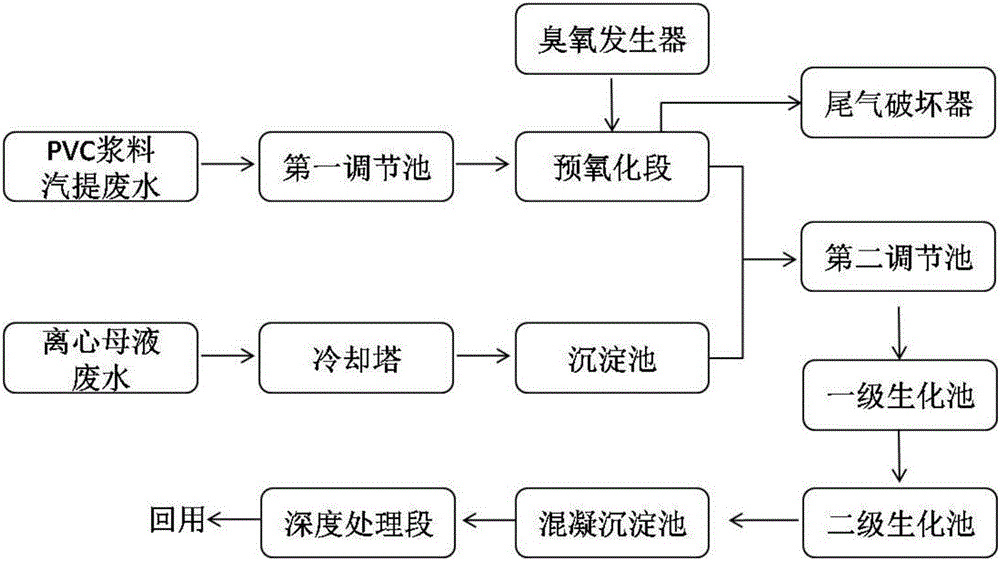

[0041] see figure 1 , PVC slurry stripping waste water with 20m 3 The flow rate of / h first enters the first regulating tank to balance the water quality and quantity, and the residence time is 8h, and then enters the microbubble pre-oxidation unit, the residence time is 30-40min, and the ozone concentration is 20-40mg / L. Remaining O 3 Under the action of the high-efficiency catalyst in the ozone tail gas destruction device, the catalytic generation of O 2 .

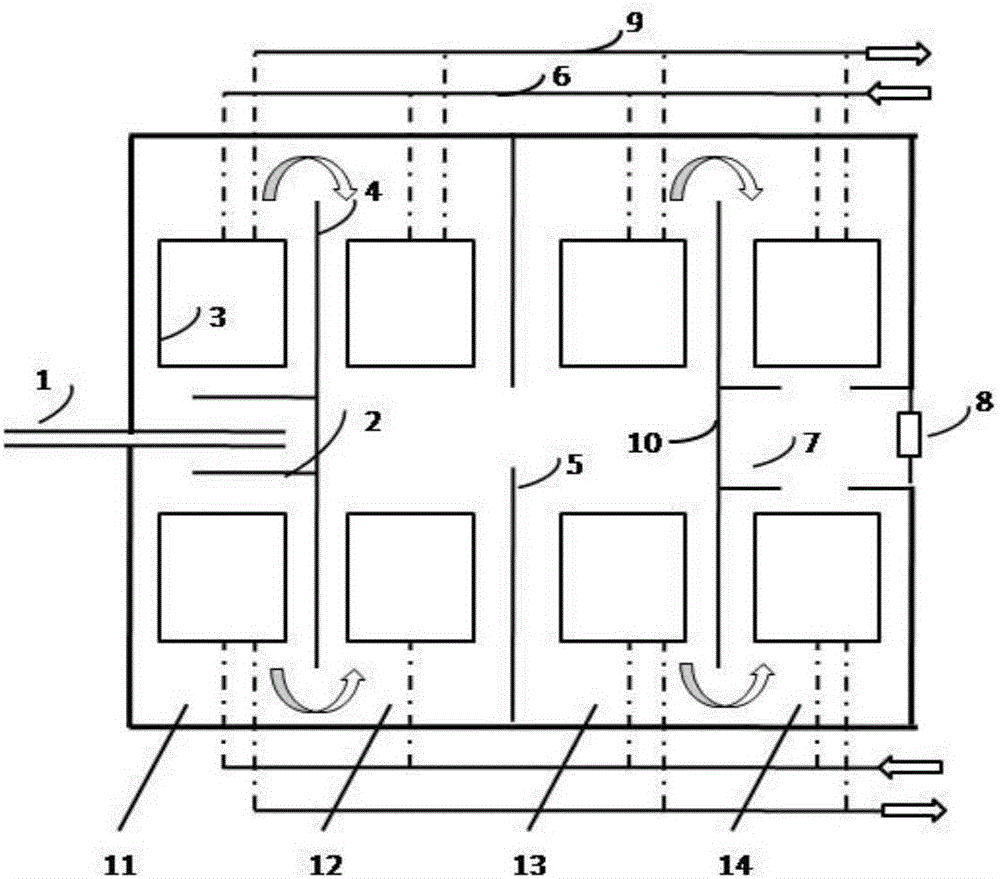

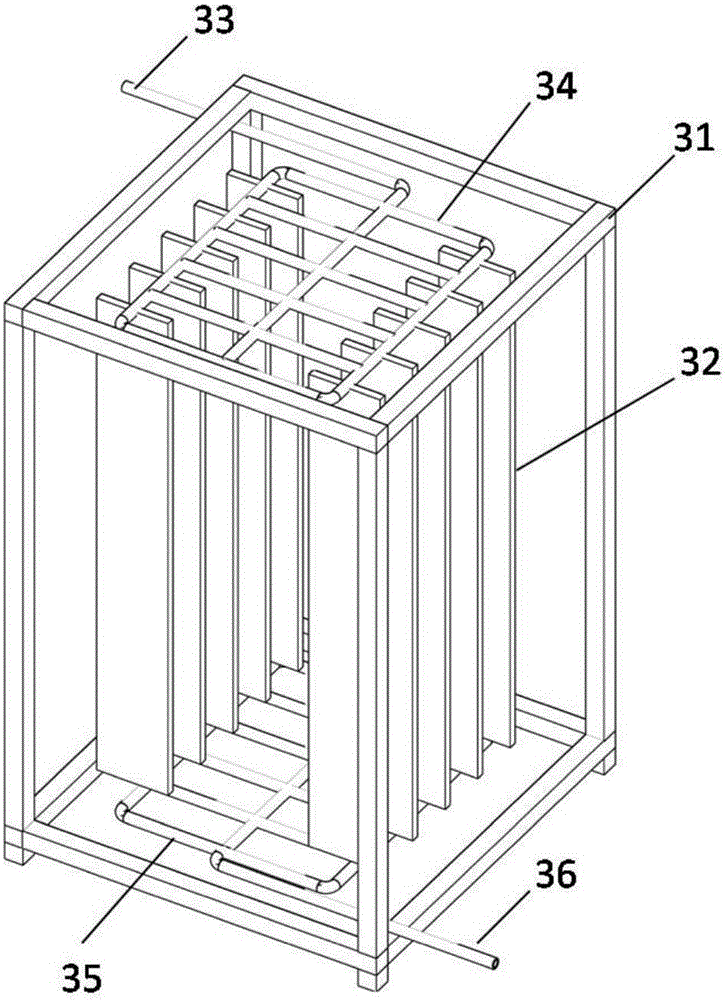

[0042] Pre-oxidized slurry stripping wastewater and cooled, pre-sedimented centrifugal mother liquor wastewater (160m 3 / h) into the second regulation pool, and then into the primary biochemical pool. The first-level biochemical pool is a stuffed biofilm reactor, and the reaction poo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com