Preparation method of thin-shell structure zirconia powder for thermal spraying

A technology of zirconia powder and thin shell structure, applied in the field of ceramic materials, can solve the problems of solidification of molten drop shell, high melting point of zirconia powder, large temperature gradient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

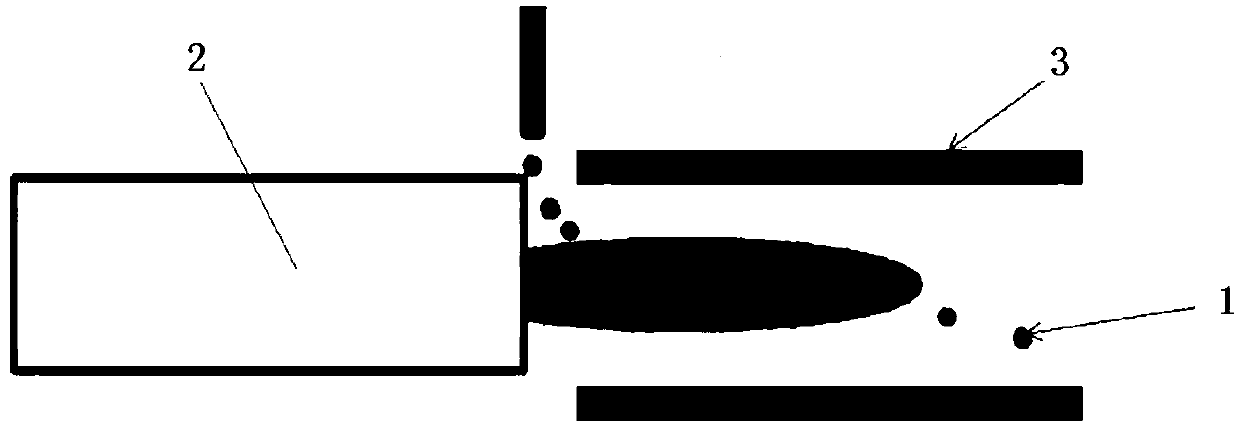

Method used

Image

Examples

Embodiment 1

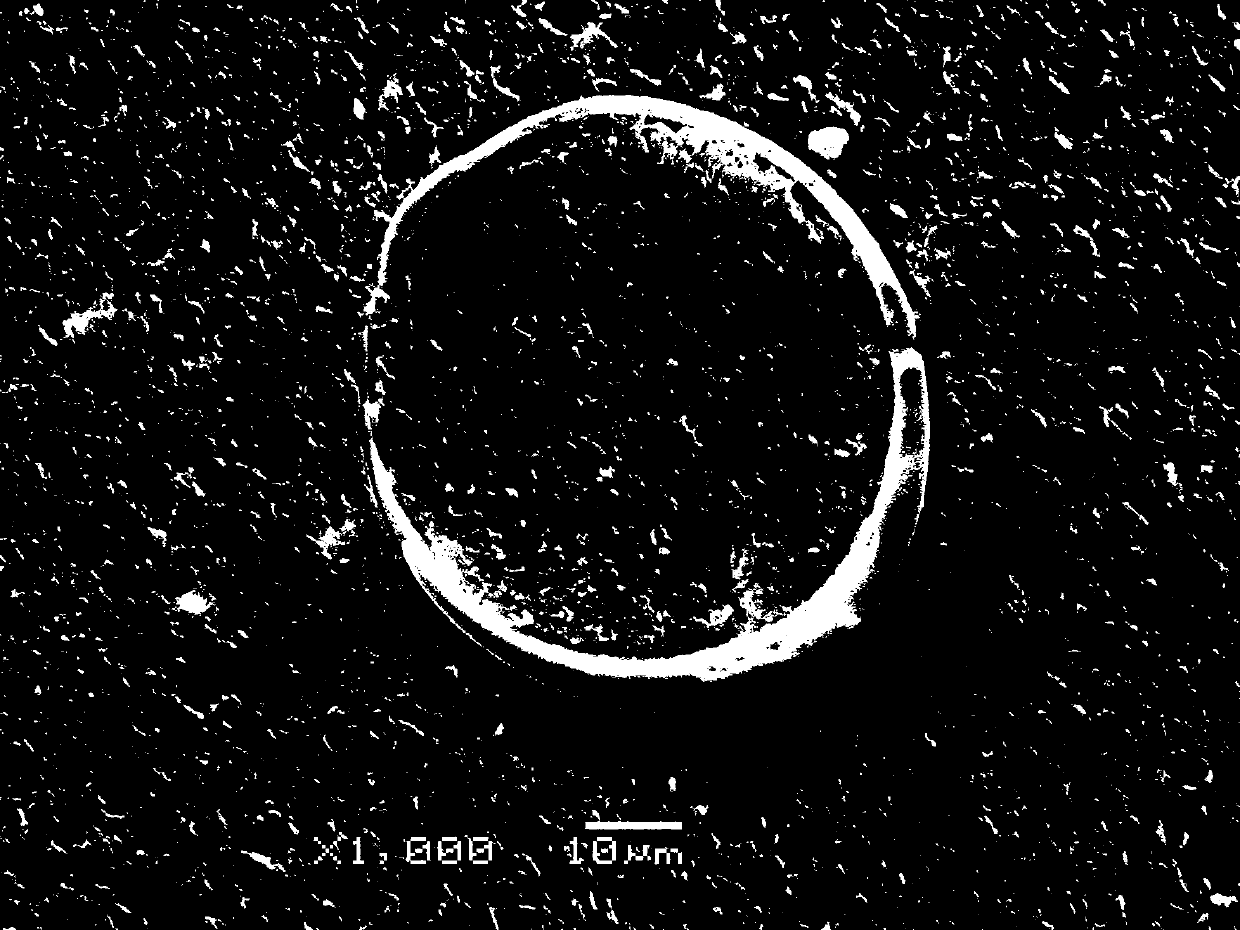

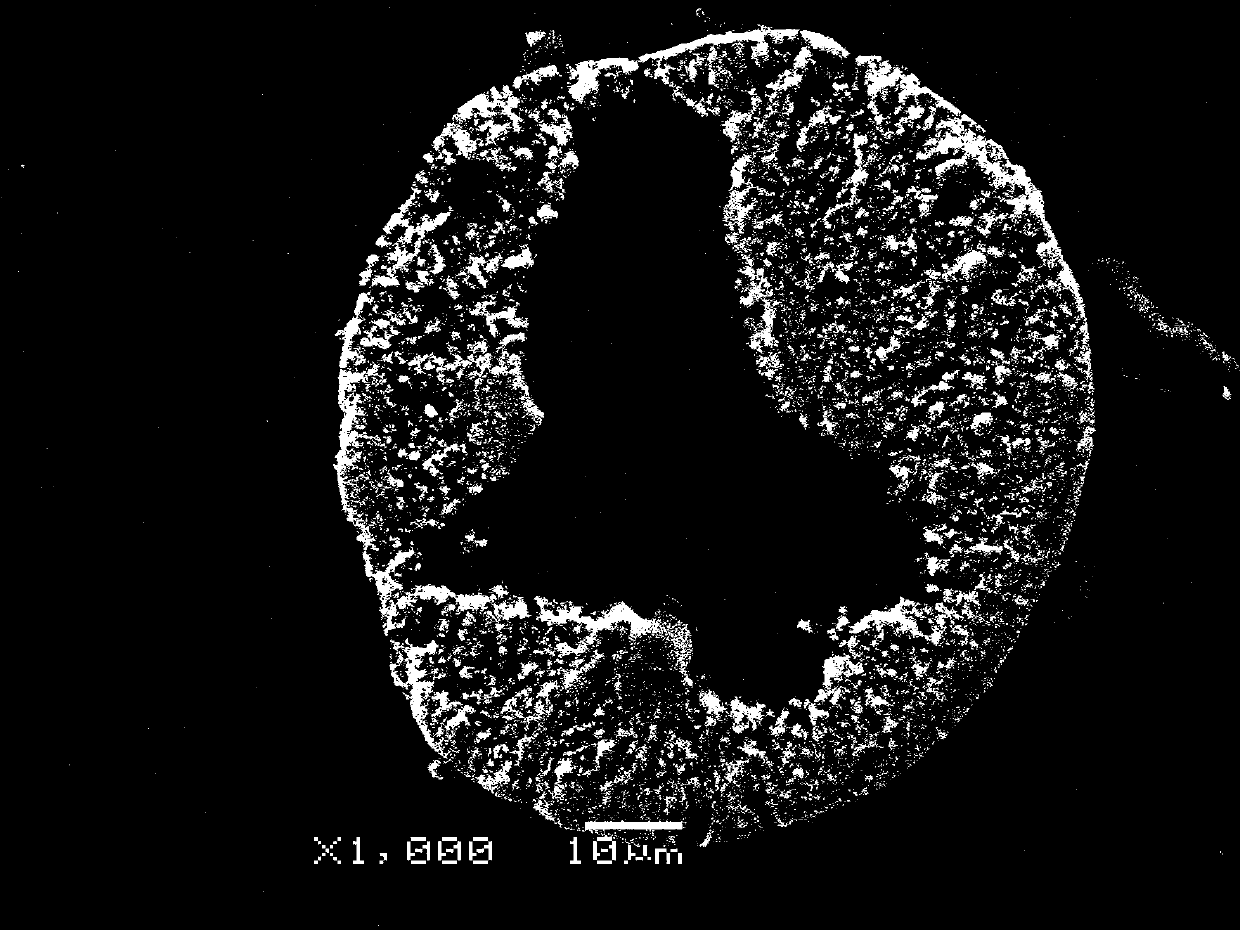

[0019] 8% yttria-stabilized zirconia powder granulated by spraying is used, the particle size ranges from 20 to 106um, and it is calcined at 800°C for 2 hours. Using METCO 9MB plasma spray gun to spheroidize, set a heat preservation zone at the exit of the spray gun with a length of 500mm and a radial direction of 40mm, collect the cooled powder at a distance of 1000mm from the exit of the heat preservation zone, and then obtain a thin shell structure with a hollowness of about 62% 8% Yttria stabilized zirconia powder. The SEM image of the cross-section of the prepared powder is attached Figure 2a , the SEM of the powder section without increasing the heat preservation zone is as follows Figure 2b . It can be seen that after increasing the heat preservation zone, the hollowness of the powder increases significantly.

Embodiment 2

[0021] 7% yttria-stabilized zirconia powder granulated by spraying is used, the particle size range is 20~106um, and it is calcined at 900°C and kept for 2 hours. Using METCO 9MB plasma spray gun for spheroidization, set a heat preservation zone at the spray gun outlet with a length of 100mm and a radial direction of 40mm, and collect the cooled powder at a distance of 1000mm outside the heat preservation zone outlet to produce a thin-shell structure zirconia powder with a hollowness of 54%. .

Embodiment 3

[0023] Use 20% calcium oxide stabilized zirconia powder granulated by spraying, with a particle size range of 20~106um, and calcined at 1000°C for 1 hour. Using METCO 9MB plasma spray gun for spheroidization, set a heat preservation zone at a distance of 300mm from the spray gun exit and a radial area of 50mm, and collect the cooled powder at a distance of 1000mm from the exit of the heat preservation zone to obtain a thin-shell structure with a hollowness of 60%. Zirconia powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com