Spinning method for thermal storage heating fiber blended core-spun double-layer structure yarn

A technology of heating fiber and double-layer structure, applied in the field of yarn processing, can solve the problems of no heating, not the best effect, low yarn and fabric strength, etc., and achieve the effect of improving the mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] One, the formation mechanism and characteristics of the double-layer structure yarn of the present invention

[0093] (1) double-layer structure yarn formation mechanism of the present invention

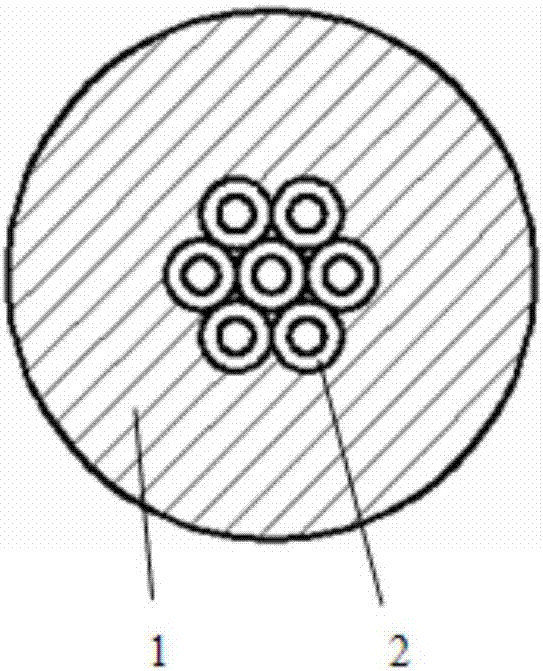

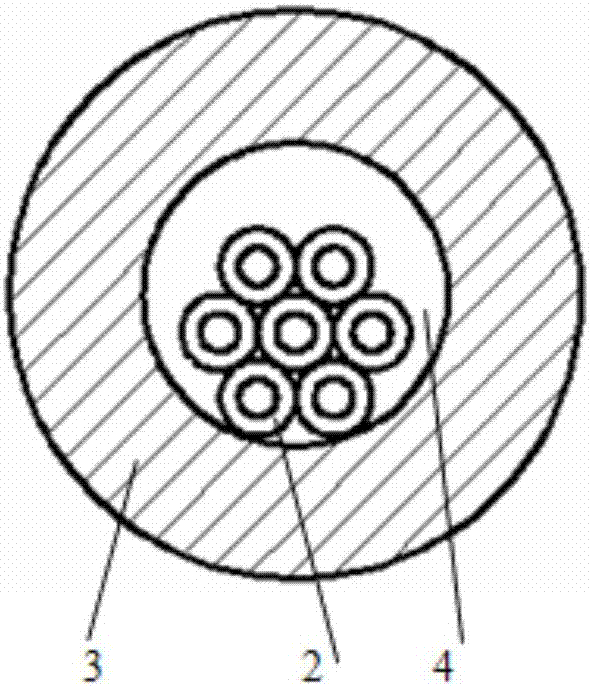

[0094] The overall structure of the yarn is core-spun hollow yarn. Its yarn forming mechanism and structure principle are as follows: figure 1 , figure 2 Shown:

[0095] First of all, the chemical fiber filament is used as the core yarn, and the outer fiber contains three kinds of short fibers, namely heat storage and heating fiber, regenerated cellulose fiber, and water-soluble vinylon, and is spun into a core-spun yarn. figure 1 As shown, 1 is heat storage and heating fiber, regenerated cellulose fiber, water-soluble vinylon staple fiber; 2 is chemical fiber filament.

[0096] Secondly, the core-spun yarn is treated with hot water to dissolve the water-soluble vinylon staple fiber, and the actual cross-sectional structure of the obtained yarn is as follows: figure 2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com