Method for manufacturing hollow micro-fine terylene denier fiber

A manufacturing method and micro-denier technology, applied in the field of textile fibers, can solve the limitations of the application field, yarn and fabric warmth retention, softness, drapability, adsorption, decontamination, filterability, waterproof and breathable performance can not meet the requirements High-grade fabrics and applications in special fields, etc., to achieve good bulkiness, significant waterproof and breathable functions, and super warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

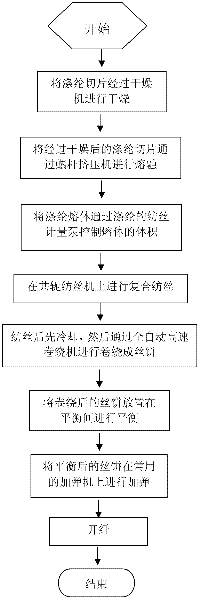

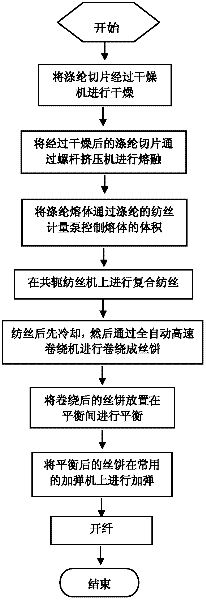

[0019] Such as figure 1 Shown, the manufacture method of polyester hollow micro-denier fiber provided by the present invention, raw material adopts polyester chip, comprises the following steps:

[0020] a) drying the polyester chips through a crystal dryer, so that the moisture content of the polyester chips after drying is less than 30ppm;

[0021] b) Melting the dried polyester chips through a screw extruder to obtain a polyester melt;

[0022] c) controlling the volume of the melt by the polyester melt formed in step (2) through a spinning metering pump of polyester;

[0023] d) The quantitative polyester melt formed in step (3) is spun through the assembly, and the spinning temperature is 298° C.;

[0024] e) After spinning, the tow is first cooled by cooling air with a temperature of 22°C to 25°C and a humidity of 65% to 85%, and then oiled by an oil metered by an oil metering pump, and finally fully automatic high-speed winding The spinning machine is wound into a si...

Embodiment 2

[0033] The manufacturing method of the polyester hollow micro-denier fiber provided by the present embodiment, its raw material and method steps are basically consistent with embodiment 1, but when the balanced silk cake in step g) of the present embodiment is texturized on a commonly used texturing machine, The draw ratio is 1.55, and the ratio of the surface speed of the friction disc to the speed at which the filament leaves the false twister, that is, the D / Y ratio is 1:1.50.

[0034] The detection index of the polyester hollow micro-denier fiber obtained in this embodiment is consistent with the detection index in Example 1.

Embodiment 3

[0036] The manufacturing method of the polyester hollow micro-denier fiber provided by the present embodiment, its raw material and method steps are basically consistent with embodiment 1, but when the balanced silk cake in step g) of the present embodiment is texturized on a commonly used texturing machine, The draw ratio is 1.72, and the ratio of the surface speed of the friction disc to the speed at which the sliver leaves the false twister, that is, the D / Y ratio is 1.75.

[0037] The detection index of the polyester hollow micro-denier fiber obtained in this embodiment is consistent with the detection index in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com