Production method of heat-accumulation and heating core-spun double-layered-structure yarn warm-keeping woven fabric

A double-layer structure, woven fabric technology, applied in the field of woven fabric processing, can solve the problems of poor air permeability, inability to achieve thermal insulation effect, no heat generation, etc., to improve strength and elasticity, improve thermal insulation effect, and improve comfort sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0149] Production method of heat-storing and heat-generating blended core-spun double-layer structure yarns for thermal insulation woven fabrics——Hanked yarn de-dimensionalization

[0150] (1) Specifications of fiber raw materials

[0151] 1. Coffee charcoal fiber: specification 1.67dtex×38mm;

[0152] 2. Modal: Specification 1.67dtex×38mm;

[0153] 3. Hollow nylon filament: specification 2.8tex / 12f;

[0154] 4. Water-soluble vinylon: 1.67dtex×38mm.

[0155] (2) Yarn specifications

[0156] Yarn specification see table 2

[0157] Table 2 Yarn specifications used in thermal woven fabrics

[0158]

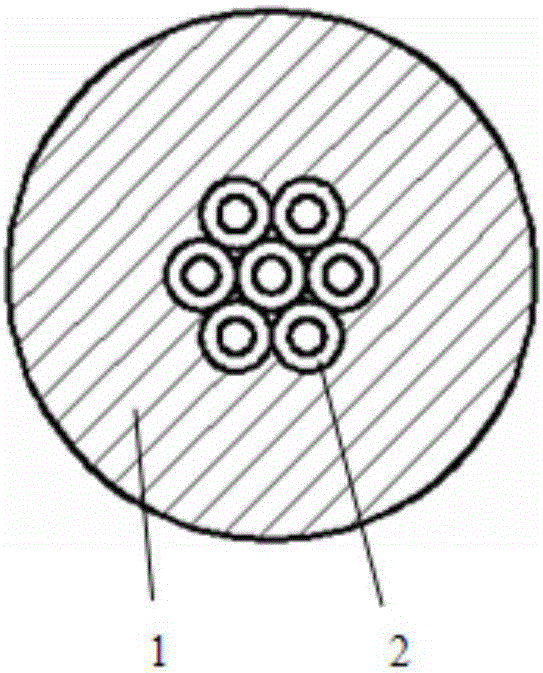

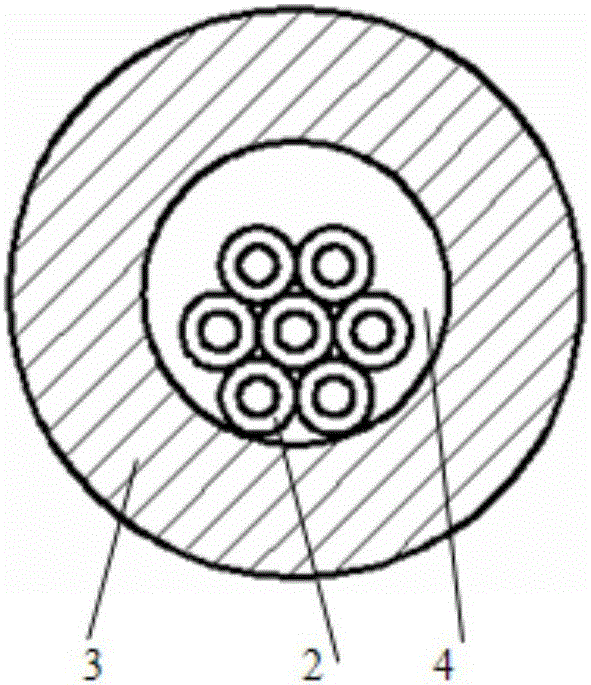

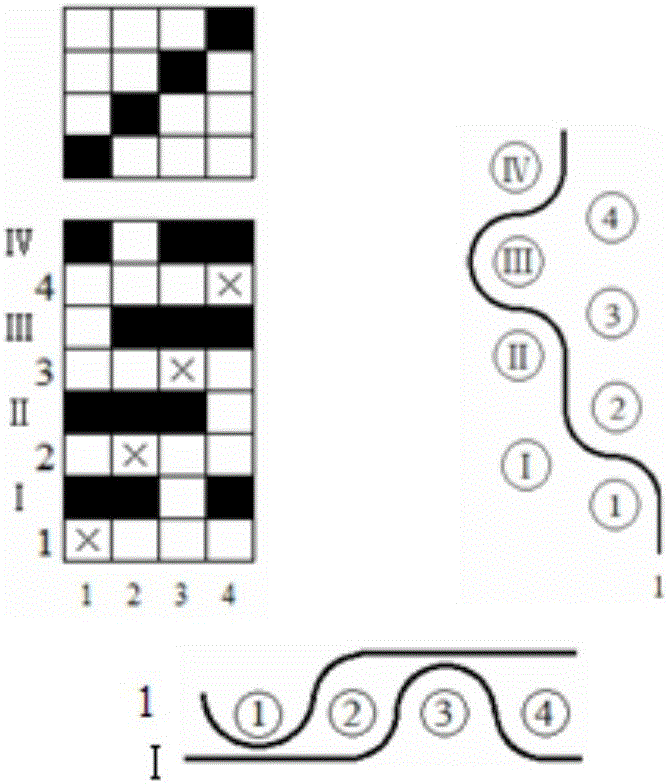

[0159] (3) Fabric specifications and organization

[0160] 146cm 28tex×28tex×354 threads / 10cm×276 threads / 10cm, double weft weaving. See Table 1 and Table 2. Weft yarn 1 is used for the surface weft of the fabric, and 1 / 3↗ is used for the surface weave; The arrangement ratio of the weft yarns is 1:1, so that both the front and back of the fabric have a good weft effect. Si...

specific Embodiment 2

[0185] Production method of heat-storing and heat-generating blended core-spun double-layer structure yarn thermal insulation woven fabric-fabric de-dimensionalization

[0186] (1) Specifications of fiber raw materials

[0187] 1. Coffee charcoal fiber: specification 1.67dtex×38mm;

[0188] 2. Modal: Specification 1.67dtex×38mm;

[0189] 3. Hollow nylon filament: specification 2.8tex / 12f;

[0190] 4. Water-soluble vinylon: 1.67dtex×38mm.

[0191] (2) Yarn specifications

[0192] Yarn specification see table 3

[0193] Table 3 Yarn specifications used in thermal woven fabrics

[0194]

[0195] (3) Fabric specifications and organization

[0196] 146cm 28tex×28tex×354 threads / 10cm×276 threads / 10cm, double weft weaving. See Table 1 and Table 3, weft yarn 2 is used for the surface weft of the fabric, and 1 / 3↗ is used for the surface weave; The arrangement ratio of weft yarns inside and outside is 1:1, so that both the front and back of the fabric have a good weft effect....

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com