Pesticide microcapsule and preparation method thereof

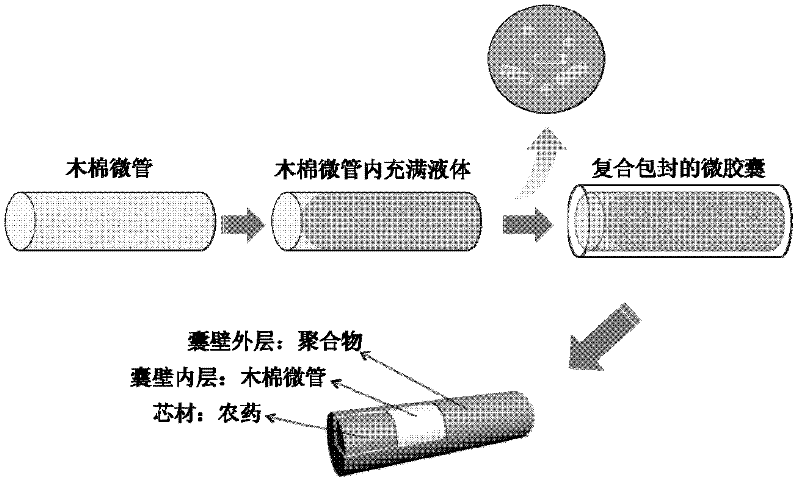

A technology of microcapsules and pesticide preparations, applied in the field of pesticide microcapsules and its preparation, can solve the problems of adverse effects on mammals, poisoning of pesticide applicators, environmental pollution, etc., and achieve the effect of increasing the amount of pesticide encapsulation and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, preparation of natural kapok fiber tube and urea-formaldehyde resin composite encapsulated clethodim microcapsules

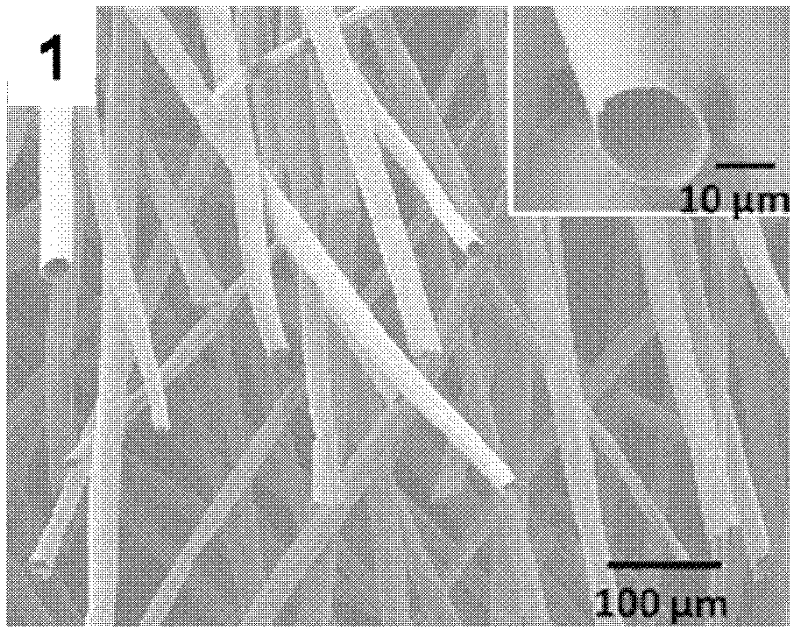

[0028] (1) Pre-treatment of natural microtubules

[0029] 1g of natural kapok fiber is chopped to 50-80μm by mechanical external force.

[0030] (2) Clethodim fills cut natural microtubules

[0031] Take 1 g of the microtubes cut short in step 1, disperse them in 10 mL of clethodim, soak them, and the kapok fiber tube is filled with clethodim due to capillary force.

[0032] (3) Encapsulation of kapok fiber tube

[0033] Directly add 2g of urea-formaldehyde prepolymer dropwise to the system in step 2 (obtained by adding 2ml of formaldehyde solution with a volume fraction of 36% and 1g of urea and stirring until completely dissolved, raising the temperature to 60°C and keeping it warm for 15min), raising the temperature of the system to 97 ~98°C, react for 1 hour. The urea-formaldehyde resin polymer is coated on the surface of the kapok f...

Embodiment 2

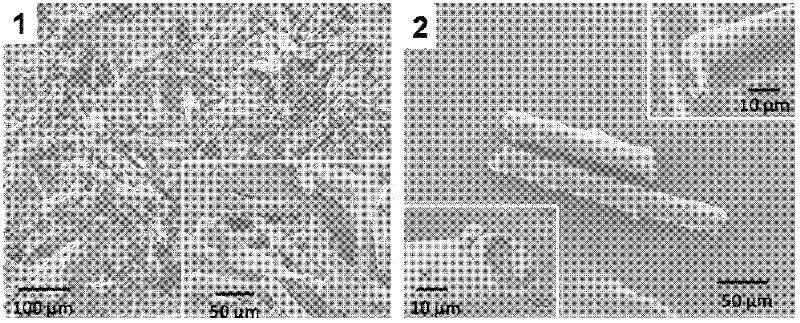

[0037] Embodiment 2, the preparation of natural kapok fiber tube and cellulose acetate composite encapsulated fluroxypyr EC (Shitalong) microcapsules

[0038] (1) Pre-treatment of natural microtubules

[0039] Cut 1g of natural kapok fiber to 100-150μm by mechanical force.

[0040] (2) Fluroxypyr EC filled with cut natural microtubules

[0041] Take 0.5 g of the short-cut microtubes in step 1 and disperse them in 10 mL of fluroxypyr EC, soak to balance the capillary absorption, and fill the kapok fiber tube with fluroxypyr EC.

[0042] (3) Encapsulation of kapok fiber tube

[0043] The kapok microtubes filled with fluroxypyr EC obtained in step (2) were immersed in 5 mL of cellulose acetate dichloromethane solution with a concentration of 5% (mass percentage), so that the kapok microtubes were covered with a layer of A cellulose acetate solution to obtain fluroxypyr emulsifiable concentrate microcapsules encapsulated by cellulose acetate and kapok fiber tubes.

[0044] (4)...

Embodiment 3

[0047] Example 3. Preparation of dimethacet microcapsules encapsulated in natural kapok fiber tube and encapsulated with polyacrylonitrile

[0048] (1) Pre-treatment of natural microtubules

[0049] 1g of natural kapok fiber is chopped to 800-900μm by mechanical external force.

[0050] (2) Dimethacet filled with cut natural microtubules

[0051] Take 0.2 g of the short-cut microtubes in step 1 and disperse them in 10 mL of dimethenamid, and soak to balance the capillary absorption, so that the kapok fiber tubes are filled with dimethacet.

[0052] (3) Encapsulation of kapok fiber tube

[0053] The kapok microtubes filled with dimethacet obtained in step (2) were immersed in 5 mL of polyacrylonitrile N, N'-dimethylformamide solution with a concentration of 5% (mass percentage content), so that The kapok microtubules are covered with a layer of polyacrylonitrile solution, and the dimethacet microcapsules encapsulated by kapok fiber microtubules and polyacrylonitrile are obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com