Pesticide microcapsule and preparation method thereof

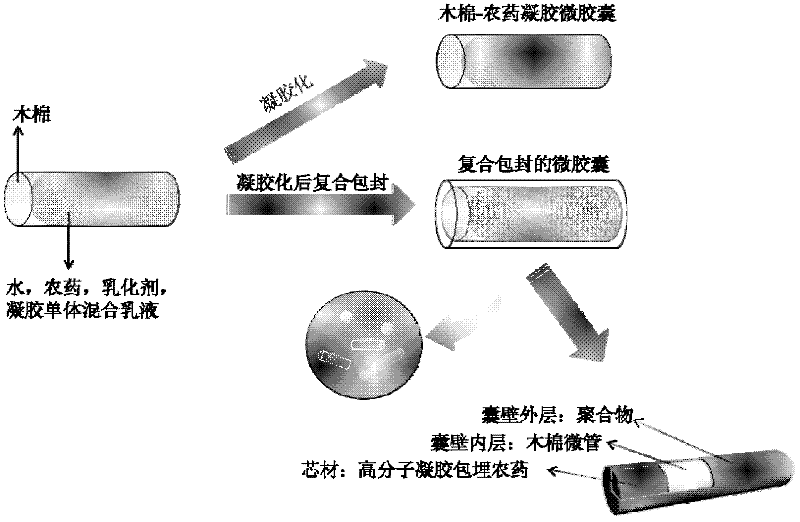

A technology for microcapsules and pesticide preparations, which is applied in the field of pesticide herbicide microcapsules and their preparation, can solve problems such as poisoning to applicators, adverse effects on mammals, environmental pollution, etc., so as to control the release of pesticides and increase the encapsulation amount of pesticides. , the effect of abundant yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1. Preparation of pesticide microcapsules with natural kapok fiber microtubes encapsulating lactofen-gelatin gel

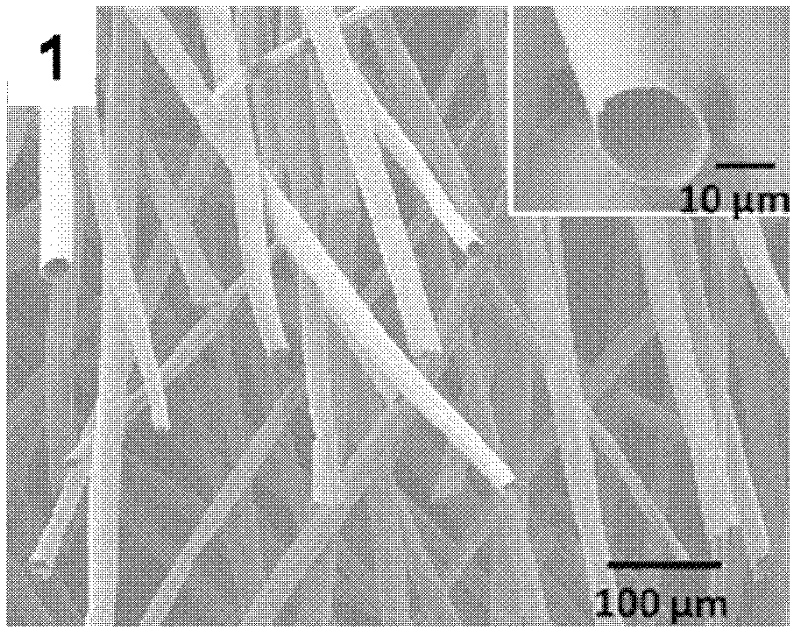

[0040] (1) Pre-treatment of natural microtubules

[0041] Cut 1g natural kapok fiber to 300-350μm with mechanical external force.

[0042] (2) Lactofop-ethyl-gelatin filled kapok microtubules

[0043] Add 10mL Lactofop-ethyl and 0.01g PEG-PPG-PEG (polyethylene glycol-polypropylene glycol-polyethylene glycol, Mn~14600) into 15ml water to make an emulsion, heat, and dissolve 6g gelatin in the emulsion in. Disperse 1 g of the chopped natural microtubes in the mixed solution and soak so that the natural microtubes are filled with the mixed solution.

[0044] (3) Filtering and cleaning the kapok in step (2), cooling to gelatinize the gelatin, and obtaining pesticide microcapsules with kapok fiber microtubes encapsulating lactofen-gelatin gel.

[0045] The encapsulation rate of the obtained lactofen-gelatin gel pesticide microcapsules is 35%.

Embodiment 2

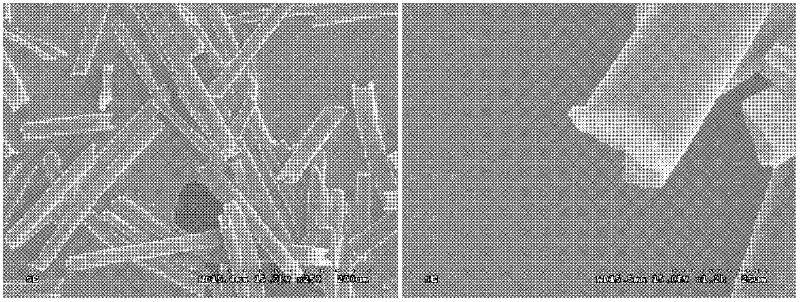

[0046] Example 2. Preparation of pesticide microcapsules with natural kapok fiber microtubes encapsulating metapyrazin EC-agar gel

[0047] (1) Pre-treatment of natural microtubules

[0048] Cut 1g natural kapok fiber to 300-350μm with mechanical external force.

[0049] (2) Metatraclofen EC-agar filled kapok microtubes

[0050] Add 8mL metazofen EC and 0.005g PEG-PPG-PEG (Mn-14600) into 25ml water to prepare an emulsion, heat, and dissolve 2g agar in the emulsion. Disperse the chopped natural microtubes in the mixed solution and soak so that the natural microtubes are filled with the mixed solution.

[0051] (3) Filter and wash the kapok in step (2), cool to gel the agar, and obtain pesticide microcapsules in which the kapok fiber microtubes encapsulate metazachlor EC-agar gel.

[0052] The encapsulation rate of the obtained metazofen EC-agarose pesticide microcapsules is 30%.

Embodiment 3

[0053] Example 3. Preparation of pesticide microcapsules with natural kapok fiber microtubes encapsulating refined haloxyfop-calcium alginate gel

[0054] (1) Pre-treatment of natural microtubules

[0055] Cut 1g natural kapok fiber to 900-1000μm with mechanical external force.

[0056] (2) Chloroxyfop-sodium alginate filled kapok microtubules

[0057] Add 5 mL of haloxyfop and 0.001 g of octylphenol polyoxyethylene ether to 20 mL of water to prepare an emulsion, and dissolve 3 g of sodium alginate in the emulsion. Disperse the chopped natural microtubes in the mixed solution and soak so that the natural microtubes are filled with the mixed solution.

[0058] (3) Filter and clean the kapok in step (2), and put in 0.1mol / L CaCl 2 In the solution, the calcium alginate gel is obtained, that is, the pesticide microcapsules in which the kapok fiber microtubes encapsulate the refined haloxyfop-calcium alginate gel are obtained.

[0059] The encapsulation rate of the obtained refined haloxyfop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com