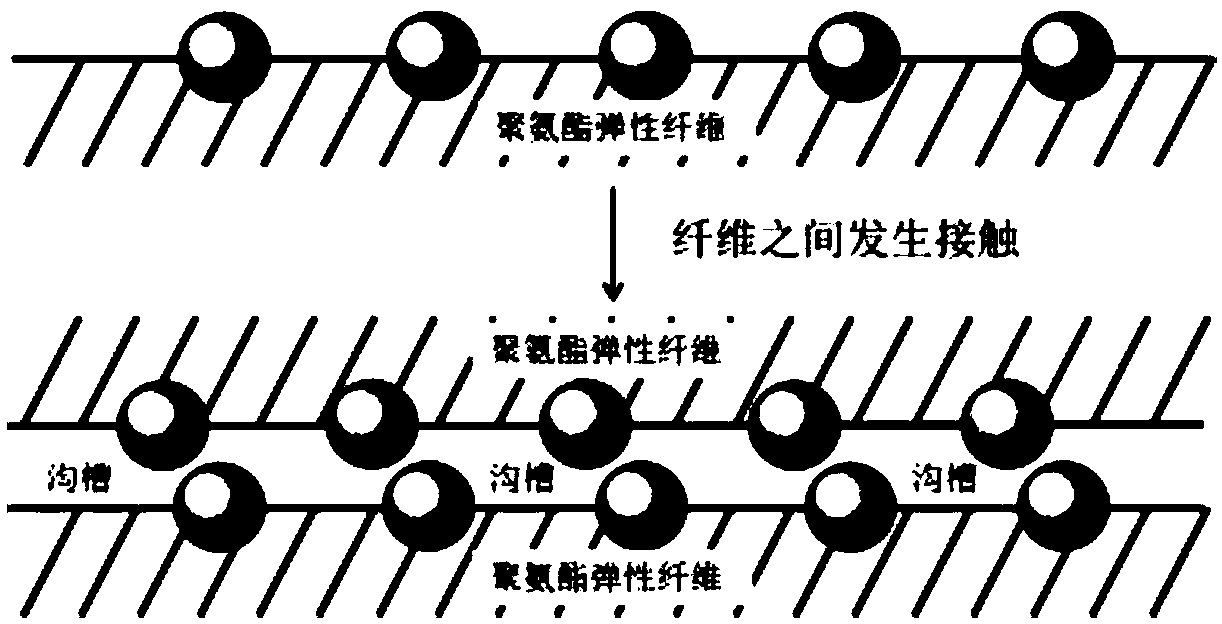

Method for preparing moisture absorption and sweat releasing polyurethane elastic fibers having skin core structure

A technology of polyurethane elasticity and skin-core structure, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of fabric moisture absorption and perspiration performance, insufficient hydrophilicity, etc., and achieve significant moisture absorption and perspiration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the skin-core structure moisture-absorbing and sweat-wicking polyurethane elastic fiber of the present invention specifically comprises the following steps:

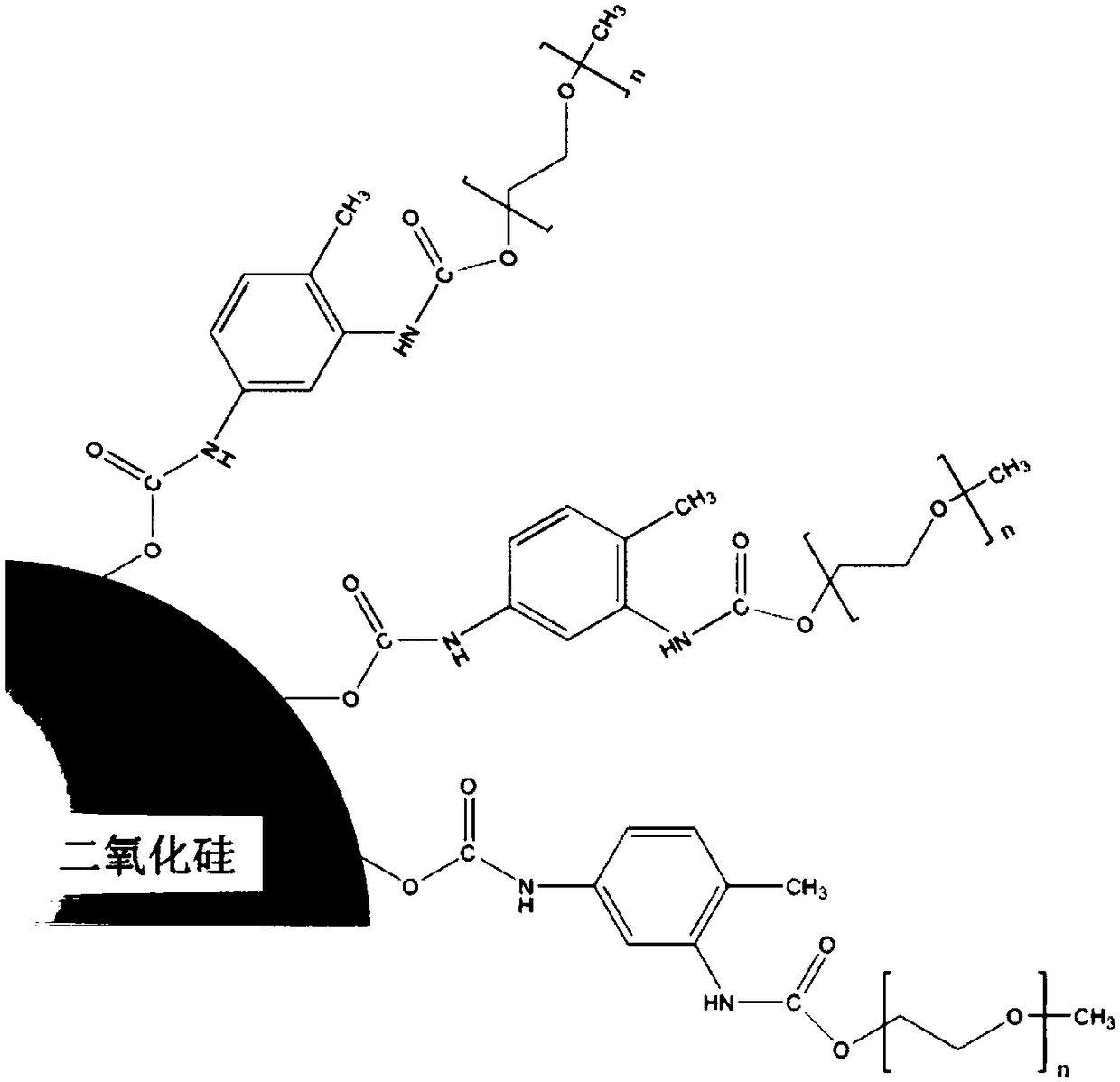

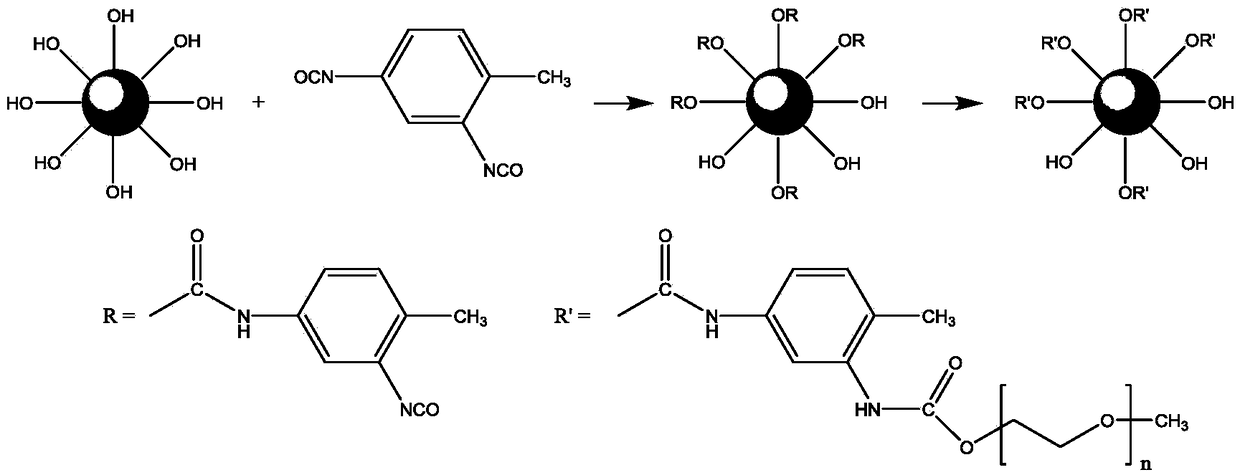

[0052] 1) Add silica particles and toluene-2,4-diisocyanate into N,N-dimethylacetamide, disperse through a ball mill for 180 minutes, and then react at a temperature of 80-100°C for 6-8 hours, and the reaction ends Afterwards, centrifuge to obtain silica particles, then disperse with N,N-dimethylacetamide, and repeat several times to obtain functionalized silica particles;

[0053] 2) Add functionalized silica particles into N,N-dimethylacetamide, disperse in a ball mill for 180 minutes, add methoxypolyethylene glycol, and react at a temperature of 70-80°C for 2-4 hours to obtain the N,N-dimethylacetamide dispersion of aqueous silica particles;

[0054] 3) In the first reactor, add diisocyanate and polyether polyol at the same time, place it at a temperature of 70-80°C, and fully carry o...

Embodiment 1

[0063] Step 1. Disperse 3.00kg of silica particles (–OH group 1.0mol / kg, average particle size 20um) in 90kg of N,N-dimethylacetamide solvent, disperse in a ball mill for 180min, then add 3.13kg of toluene dropwise -2,4-Diisocyanate, reacted at 90°C for 6 hours under the protection of nitrogen, filtered with a filter screen after the reaction, and washed with N,N-dimethylacetamide at the same time to obtain functionalized silica particles (-NCO group Group 0.71mol / kg);

[0064] Step 2. Disperse 2.00kg of functionalized silica particles in 27.72kg of N,N-dimethylacetamide, and after dispersing in a ball mill for 180min, add 1.06kg of methoxypolyethylene glycol (molecular weight 750) dropwise, nitrogen React at 80°C for 3.5 hours under protection to obtain hydrophilic silica particles;

[0065] Step 3. Send 237.10kg polytetramethylene ether glycol (molecular weight 1800) and 53.90kg 4,4-diphenylmethane diisocyanate to the first reactor at the same time, the reaction time is 2.2...

Embodiment 2

[0073] Step 1. Disperse 3.00kg of silica particles (–OH group 1.0mol / kg, average particle size 20um) in 90kg of N,N-dimethylacetamide solvent, disperse in a ball mill for 180min, then add 3.13kg of toluene dropwise -2,4-Diisocyanate, reacted at 90°C for 6 hours under the protection of nitrogen, filtered with a filter screen after the reaction, and washed with N,N-dimethylacetamide at the same time to obtain functionalized silica particles (-NCO group Group 0.71mol / kg);

[0074] Step 2. Disperse 2.00kg of functionalized silicon dioxide particles in 27.72kg of N,N-dimethylacetamide, after dispersing in a ball mill for 180min, add dropwise 1.06kg of methoxypolyethylene glycol (molecular weight 2000), nitrogen React at 80°C for 3.5 hours under protection to obtain hydrophilic silica particles;

[0075] Step 3. Send 237.10kg polytetramethylene ether glycol (molecular weight 1800) and 53.90kg 4,4-diphenylmethane diisocyanate to the first reactor at the same time, the reaction time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com