Compact spinning yarn produced through polylactic acid fiber and combed fine stable cotton blending and production method and application of compact spinning yarn

The technology of a polylactic acid fiber and a production method, which is applied in the textile field, can solve the problems such as the inability to obtain medium-count yarn or high-count yarn, the polylactic acid fiber has a large elongation at break, and is prone to wrinkle, and achieves weight unevenness. Improves gloss and skin-friendly properties, and protects fiber integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

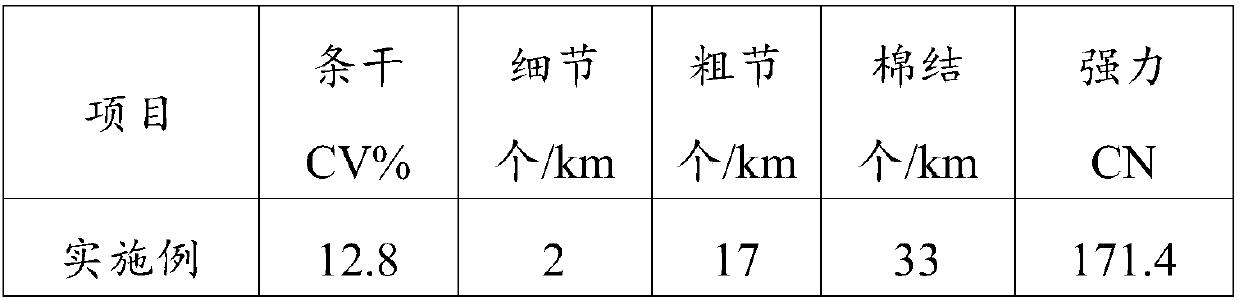

Examples

Embodiment

[0052] Polylactic acid fiber is blended with combed fine-staple cotton to produce compact spinning, which is produced through the following process steps:

[0053] 1) Cleaning process

[0054] In order to protect the polylactic acid fiber from being damaged as much as possible, the process should be shortened as much as possible, and the impact method should be reduced as much as possible. Increase the opening. The falling speed of the beater of the cotton catching machine is 3mm each time, the speed is 960r / min, the speed of the rotary trolley is 2.8r / min, the blade extends out of the rib 3mm, the speed of the beater is 800r / min, the speed of the fan is 950r / min, the distance between the beater and the balance roller is 12mm, Lap roller speed 12r / min,

[0055] Polylactic acid fiber: the dry weight of the lap is 374g / m, and the length of the lap is 30.6m;

[0056] Fine-staple cotton: the dry weight of the lap is 375.5g / m, and the lap length is 36.5m;

[0057] 2) Carding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com