Sportswear shell fabric and production method thereof

A technology for sportswear and fabrics, applied in the field of textile fibers, can solve problems such as unfavorable moisture absorption and perspiration, and achieve the effects of good anti-ultraviolet performance, cost reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

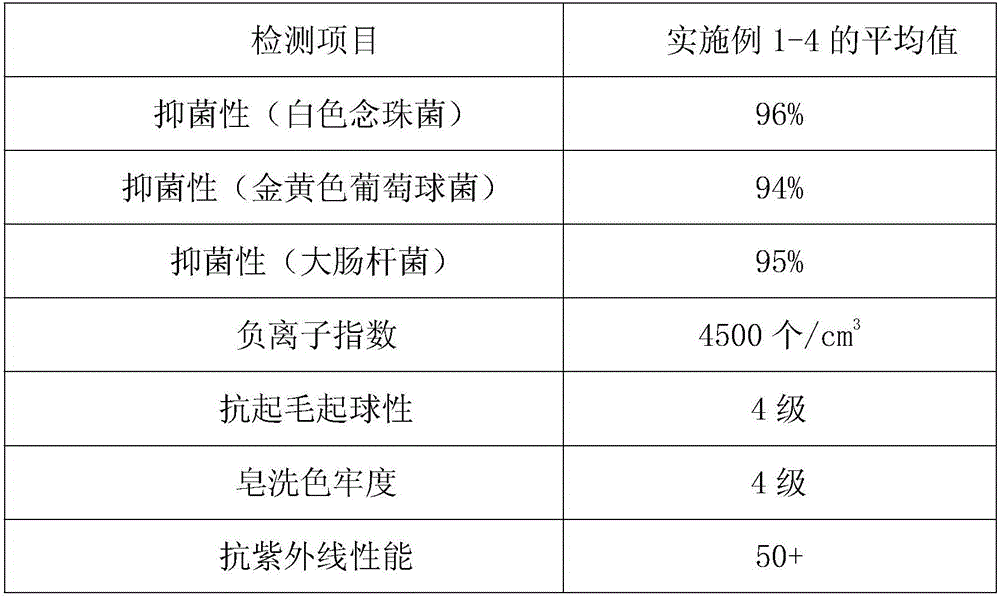

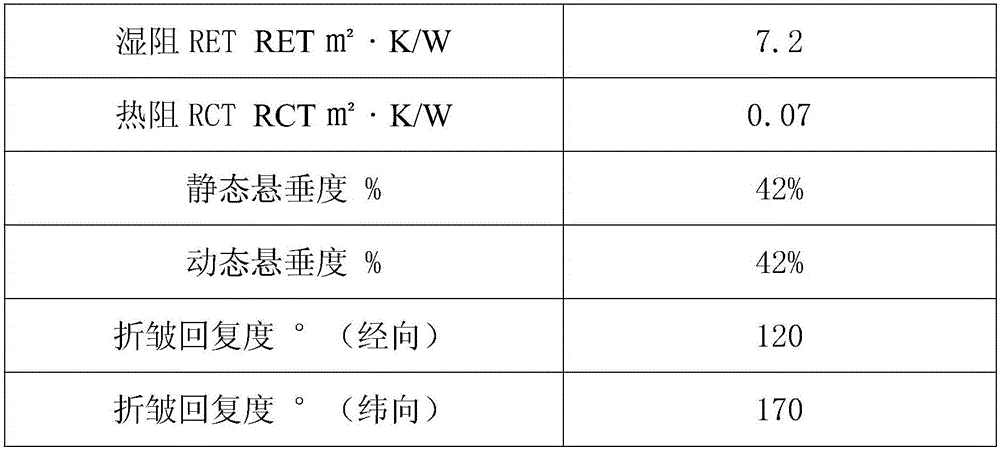

Examples

Embodiment 1

[0039] A preparation method for sportswear fabric, comprising the following steps:

[0040] A. Put the Coolplus fiber into 48°C water after simple cleaning and drying, add sodium hydroxide and dispersant to adjust the pH value of the solution to 9-10, and make an alkaline solution;

[0041] B. Add pearl powder with a particle size of 10-30 microns in the alkaline solution, and then perform ultrasonic treatment on the solution, the treatment condition is 40kHz, and the time is 20min, and then add nano-scale anion finishing agent and nano-scale antibacterial finishing agent In the neutral solution, while stirring, the temperature was raised to 95°C at a rate of 5°C / min, and kept for 12 minutes;

[0042]C. Put the treated Coolplus fiber into the washing machine, clean it and dry it;

[0043] D. Send the raw materials into the cotton blender, and mix the superfine polyester fiber, special-shaped polyester fiber and Coolplus fiber;

[0044] E. Send the mixed superfine polyester f...

Embodiment 2

[0060] A preparation method for sportswear fabric, comprising the following steps:

[0061] A. Put the Coolplus fiber into 45°C water after simple cleaning and drying, add sodium hydroxide and dispersant to adjust the pH value of the solution to 9-10, and make an alkaline solution;

[0062] B. Add pearl powder with a particle size of 10-30 microns in the alkaline solution, and then ultrasonically treat the solution. The treatment condition is 30kHz, and the time is 15min. Then add nano-scale negative ion finishing agent and nano-scale antibacterial finishing agent to alkali In the neutral solution, while stirring, the temperature was raised to 100°C at a rate of 3°C / min, and kept for 15 minutes;

[0063] C. Put the treated Coolplus fiber into the washing machine, clean it and dry it;

[0064] D. Send the raw materials into the cotton blender, and mix the superfine polyester fiber, special-shaped polyester fiber and Coolplus fiber;

[0065] E. Send the mixed superfine polyest...

Embodiment 3

[0081] A preparation method for sportswear fabric, comprising the following steps:

[0082] A. Put the Coolplus fiber into 45°C water after simple cleaning and drying, add sodium hydroxide and dispersant to adjust the pH value of the solution to 9-10, and make an alkaline solution;

[0083] B. Add pearl powder with a particle size of 10-30 microns in the alkaline solution, and then ultrasonically treat the solution. The treatment condition is 50kHz, and the time is 15min. Then add nano-scale negative ion finishing agent and nano-scale antibacterial finishing agent to alkali In the neutral solution, while stirring, the temperature was raised to 98°C at a rate of 10°C / min, and kept for 10 minutes;

[0084] C. Put the treated Coolplus fiber into the washing machine, clean it and dry it;

[0085] D. Send the raw materials into the cotton blender, and mix the superfine polyester fiber, special-shaped polyester fiber and Coolplus fiber;

[0086] E. Send the mixed superfine polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com