Hygroscopic and sweat releasing knitted fabric with shape memory function and processing method thereof

A shape memory, knitted fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of unsatisfactory wear performance of knitted fabrics, unsatisfactory shape memory function of knitted fabrics, and unsatisfactory shape memory function of natural fibers. , to achieve good moisture absorption and perspiration performance, the effect of improving the wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Selection of raw materials:

[0023] Inner layer material: 100D / 36FDTY shape memory fiber;

[0024] Outer layer material: 46N / 1C80 / T20 cotton bale shape memory functional fiber core-spun yarn.

[0025] 2. Weaving process:

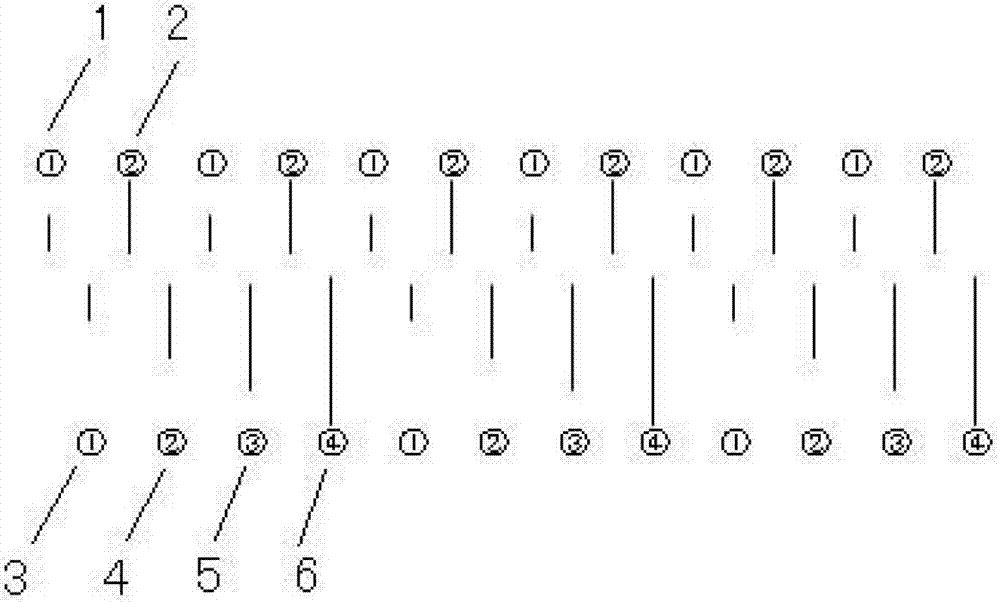

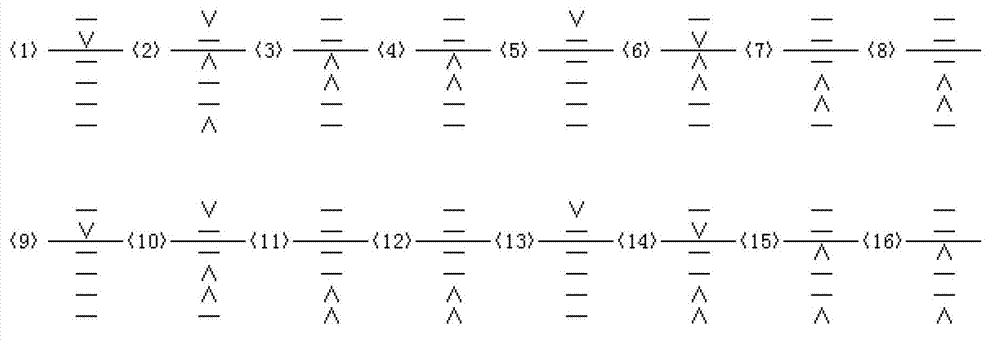

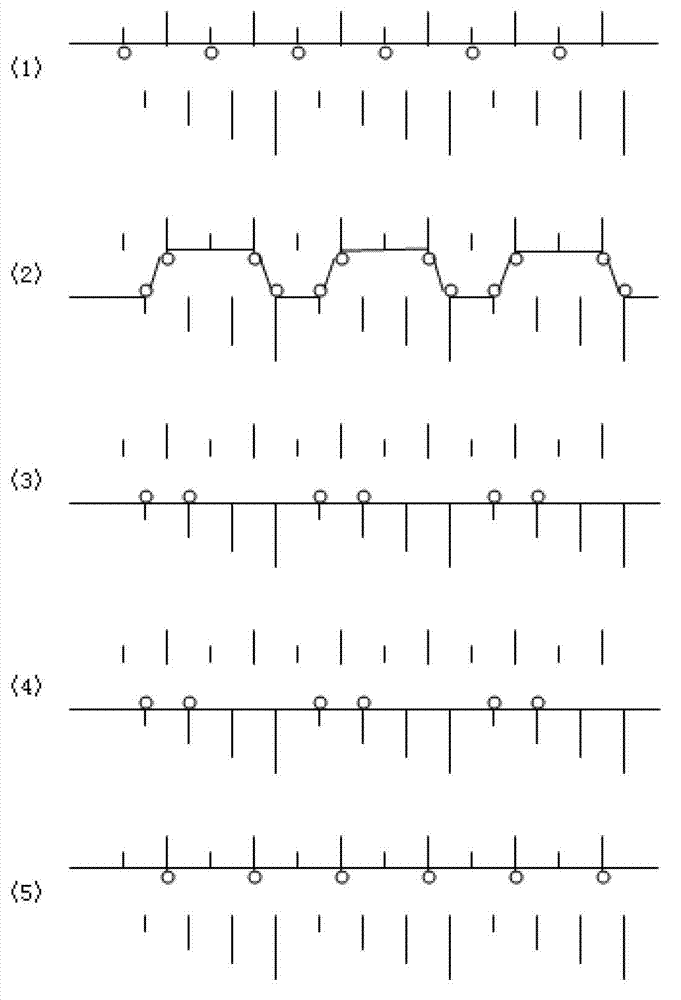

[0026] Choose Meyer-4-1 1.6QC type double-sided machine, machine number 26#, 18G gauge, cylinder diameter 34", knitting needle according to figure 1 Arranged as shown, the triangles are arranged as figure 2 Arranged as shown, press image 3 Weaving according to the weaving diagram, the weaving process is as follows:

[0027] A. Yarn usage: Yarn 100D / 36F DTY for the 1st, 2nd, 5th, 6th, 9th, 10th, 13th, and 14th routes;

[0028] Yarn 46N / 1C80 / T20 for the 3rd, 4th, 7th, 8th, 11th, 12th, 15th, and 16th routes;

[0029] B. Arrangement of knitting needles: rib to needle;

[0030] There are 2 rows of upper needle row, 1 low and 1 high, and 4 rows of lower needle row, 1 2 3 4;

[0031] C. Coil knitting: the first way uses 100D polyester yarn to d...

Embodiment 2

[0056] 1. Selection of raw materials:

[0057] Inner layer material: 75D / 36F DTY shape memory fiber;

[0058] Outer layer material: 52N / 1C70 / T30 cotton bale shape memory functional fiber core-spun yarn.

[0059] 2. Weaving process:

[0060] Choose a Meyer-4-1 1.6QC double-sided machine, machine number 26#, 18G gauge, cylinder diameter 34", knitting needles according to figure 1 Arranged as shown, the triangles are arranged as figure 2 Arranged as shown, press image 3 Weaving according to the weaving diagram, the weaving process is as follows:

[0061] A. Yarn usage: Yarn 75D / 36F DTY for the 1st, 2nd, 5th, 6th, 9th, 10th, 13th, and 14th routes;

[0062] Yarn 52N / 1C70 / T30 for the 3rd, 4th, 7th, 8th, 11th, 12th, 15th, and 16th routes;

[0063] B. Arrangement of knitting needles: rib to needle;

[0064] There are 2 rows of upper needle row, 1 low and 1 high, and 4 rows of lower needle row, 1 2 3 4;

[0065] C. Coil knitting: the first way uses 75D polyester yarn to make on...

Embodiment 3

[0090] 1. Selection of raw materials:

[0091] Inner layer material: 100D / 72F DTY shape memory fiber;

[0092] Outer layer material: 46N / 1C70 / T30 cotton bale shape memory functional fiber core-spun yarn.

[0093] 2. Weaving process:

[0094] Choose Meyer-4-1 1.6QC type double-sided machine, machine number 26#, 18G gauge, cylinder diameter 34", knitting needle according to figure 1 Arranged as shown, the triangles are arranged as figure 2 Arranged as shown, press image 3 Weaving according to the weaving diagram, the weaving process is as follows:

[0095] A. Yarn usage: Yarn 100D / 72F DTY for the 1st, 2nd, 5th, 6th, 9th, 10th, 13th, and 14th routes;

[0096] Yarn 46N / 1C70 / T30 for the 3rd, 4th, 7th, 8th, 11th, 12th, 15th, and 16th routes;

[0097] B. Arrangement of knitting needles: rib to needle;

[0098] There are 2 rows of upper needle row, 1 low and 1 high, and 4 rows of lower needle row, 1 2 3 4;

[0099] C. Coil knitting: the first way uses 100D polyester yarn to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com