Cotton fabric treatment process based on liquid ammonia and mercerizing combined finishing

A treatment process, technology for cotton fabrics, applied in the direction of fiber treatment, mercerizing of indefinite length fabrics, plant fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

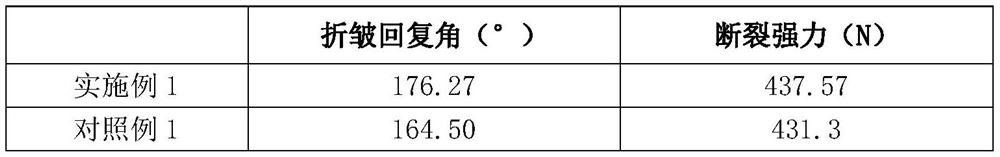

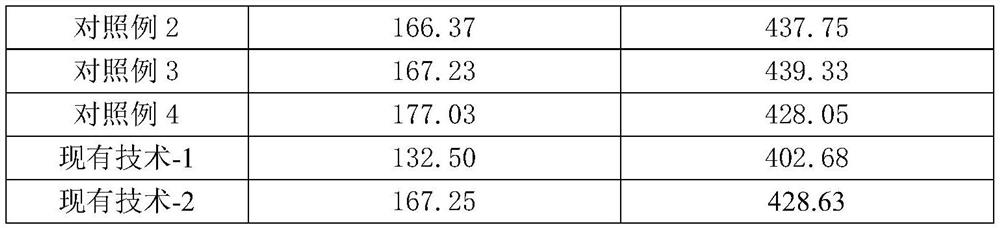

Examples

Embodiment 1

[0030] A cotton fabric treatment process based on combined finishing of liquid ammonia and mercerizing: singeing → desizing → liquid ammonia → mercerizing → liquid ammonia → tenter → preshrinking;

[0031] The specific process of the desizing process is as follows: the fabric is immersed in the enzyme liquid → steamed (stacked at 100°C for 20 minutes) → washed with water (95°C) → dried. Conditions: desizing enzyme 3g / L; penetrant 4g / L; chelating agent 2g / L; vehicle speed 70m / min;

[0032] The specific flow of the liquid ammonia process is: cloth feeding→pre-drying→cooling→liquid ammonia treatment (dipping liquid ammonia for 15s→drying)→steaming (95°C)→water washing (95°C)→drying→cloth falling . Conditions: vehicle speed 60m / min; temperature of treatment chamber 80°C; pH value of falling cloth 6;

[0033] The specific process of the mercerizing process is as follows: the fabric is immersed in the lye (5min)→washed (with tension applied, 95°C)→neutralized and the pH value of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com