Function textile with nanometer composite structure produced by nanometer protein material and method of preparation

A nanocomposite, textile technology, applied in nanotechnology for materials and surface science, textiles and papermaking, nanotechnology, etc., can solve problems such as no cotton fabrics, and achieve the effect of meeting environmental friendliness and enhancing UV protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Composition of Emulsion A:

[0061] Nano Wool 5%

[0062] h 2 o 2 1%

[0063] NaOH to adjust the pH to 12

[0064] other water

[0065] Composition of Emulsion B:

[0066] BTCA 3%

[0067] CA 3%

[0068] NaH 2 PO 2 3%

[0069] other water

[0070] Composition of Emulsion C:

[0071] AV920 20%

[0072] other water

[0073] process

[0074] S1 The fabric is dipped and rolled twice in emulsion A (residual rate 100%)→steam drying (100°C, 10 minutes, saturated steam)

[0075] S2 The fabric obtained in S1 is dipped and rolled twice in emulsion B (reduction rate 100%)→drying (80°C, 3 minutes)→baking (180°C, 1 minute)

[0076] S3 The fabric obtained in S2 is dipped twice in emulsion C and then rolled → dried (80° C., 3 minutes) → baked (180° C., 1 minute) → washed and dried.

[0077] The specific properties of the treated fabric are as follows:

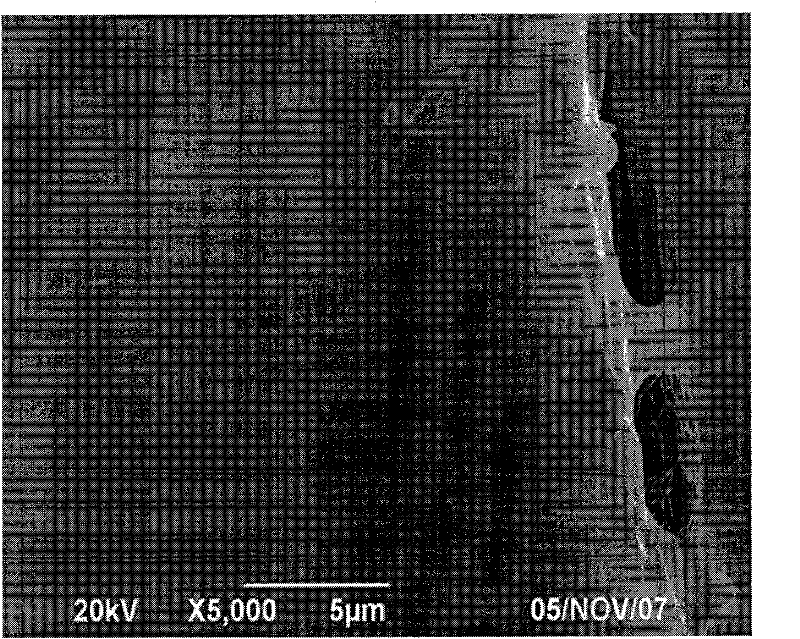

[0078] 1. Surface morphology

[0079] image 3 Be the scanning elect...

Embodiment 2

[0093] Composition of Emulsion A:

[0094] Nano Wool 15%

[0095] h 2 o 2 5%

[0096] NaOH to adjust the pH to 10

[0097] other water

[0098] Composition of Emulsion B:

[0099] BTCA 5%

[0100] CA 2%

[0101] NaH 2 PO 2 8%

[0102] other water

[0103] Composition of Emulsion C:

[0104] CEM 15%

[0105] other water

[0106] process

[0107] S1 The fabric is dipped and rolled twice in emulsion A (passing rate 80%)→steam drying (100°C, 20 minutes, saturated steam)

[0108] S2 The fabric obtained in S1 is dipped and rolled twice in emulsion B (reduction rate 100%)→drying (95°C, 5 minutes)→baking (160°C, 3 minutes)

[0109] S3 padding the fabric obtained in S2 in emulsion C→drying (90°C, 3 minutes)→baking (170°C, 2 minutes)→washing and drying.

Embodiment 3

[0111] Composition of Emulsion A:

[0112] Nano Wool 20%

[0113] h 2 o 2 8%

[0114] NaOH to adjust pH to 13

[0115] other water

[0116] Composition of Emulsion B:

[0117] BTCA 1%

[0118] CA 6%

[0119] NaH 2 PO 2 8%

[0120] other water

[0121] Composition of Emulsion C:

[0122] CEM 10%

[0123] other water

[0124] process

[0125] S1 The fabric is dipped and rolled twice in emulsion A (residue rate 90%)→steam drying (100°C, 10 minutes, saturated steam)

[0126] S2 The fabric obtained in S1 is dipped and rolled twice in emulsion B (reduction rate 100%)→drying (95°C, 5 minutes)→baking (160°C, 3 minutes)

[0127] S3 padding the fabric obtained in S2 in emulsion C→drying (80°C, 3 minutes)→baking (170°C, 2 minutes)→washing and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com