Fixed-sealing pole column

A technology of solid-sealed poles and cylindrical parts, applied in high-voltage air circuit breakers, electrical components, electric switches, etc., can solve problems such as failure of vacuum interrupter, cracking of stainless steel welding surface, deformation of stainless steel layer, etc., and achieve weight reduction , improve performance, meet the environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

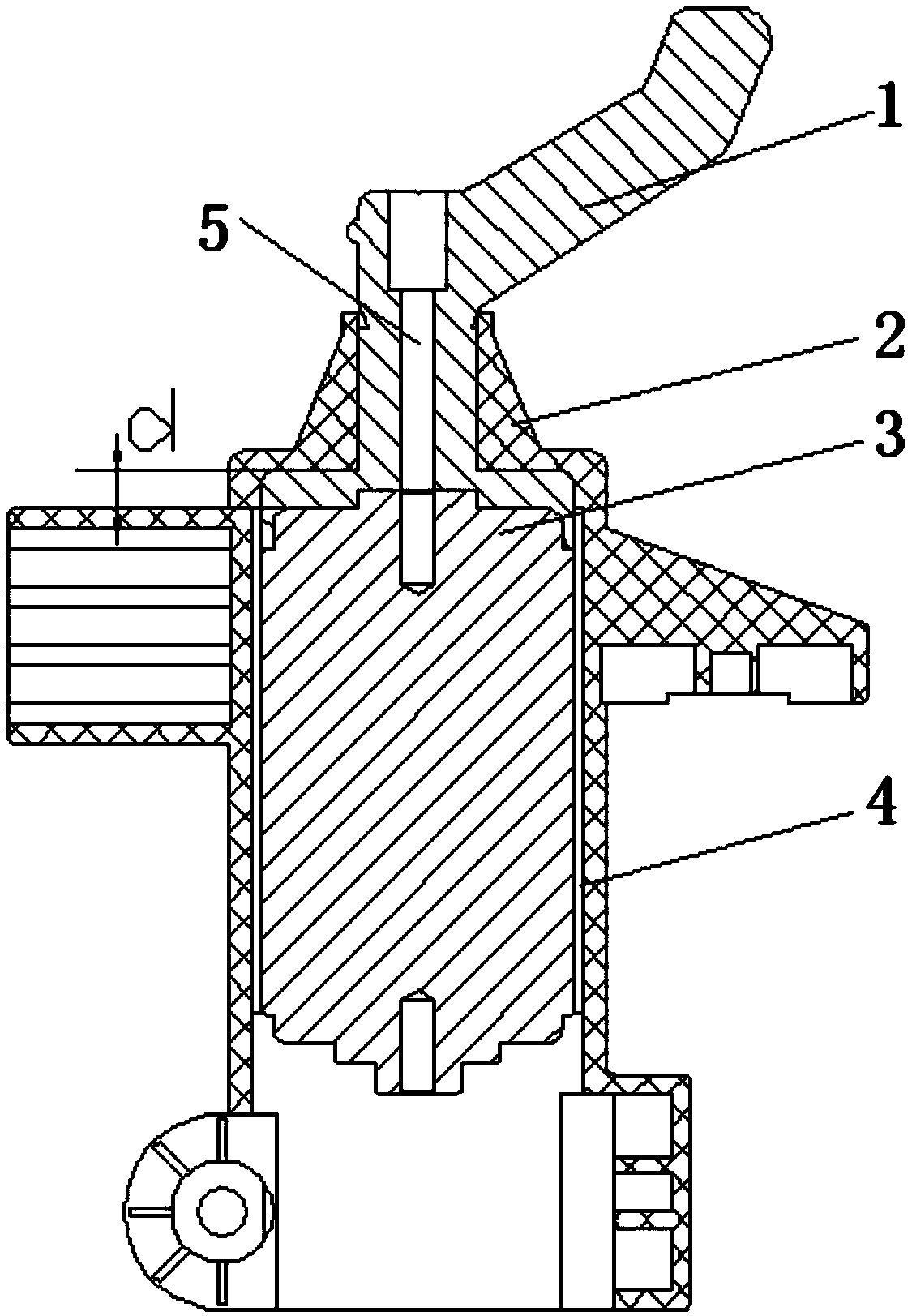

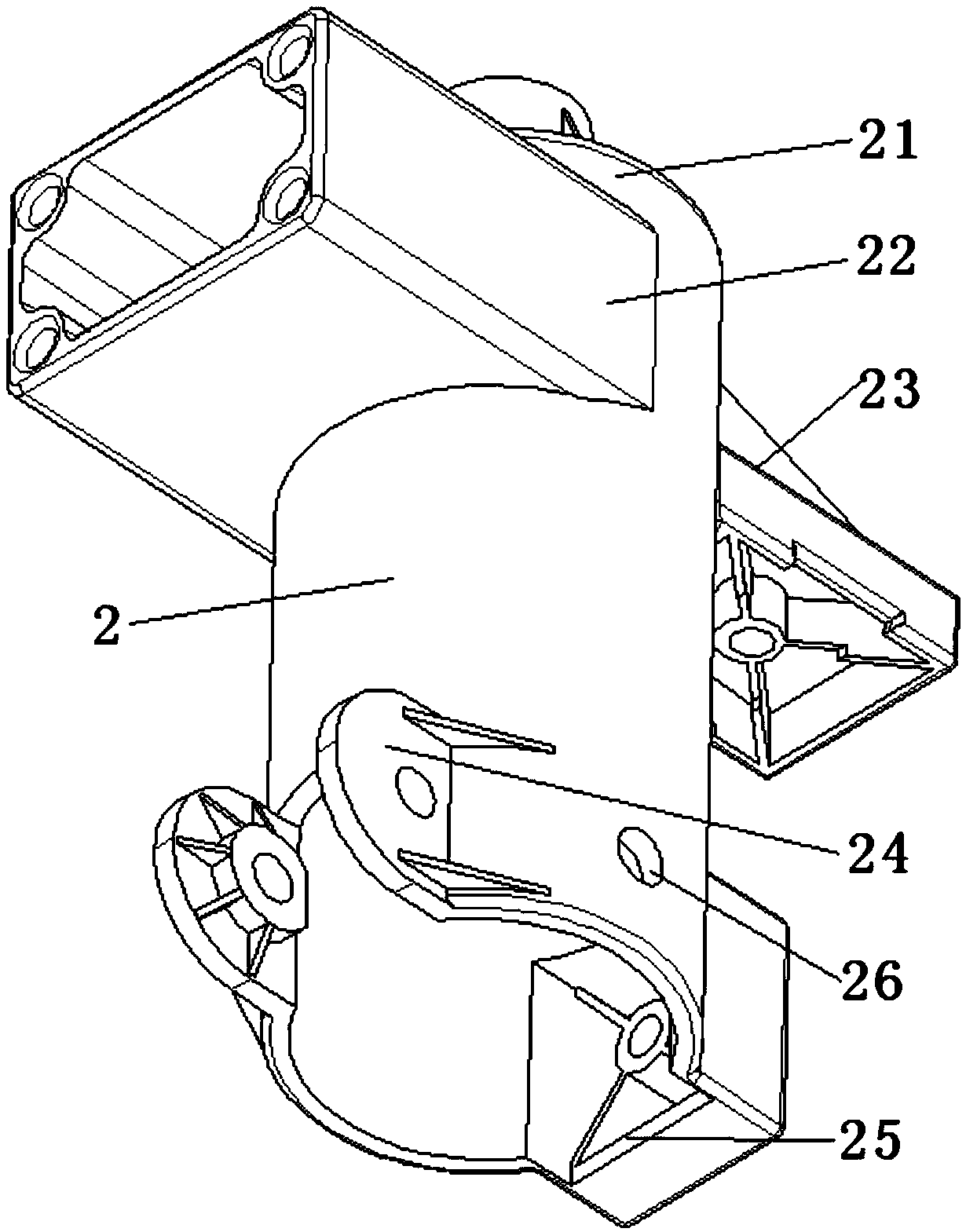

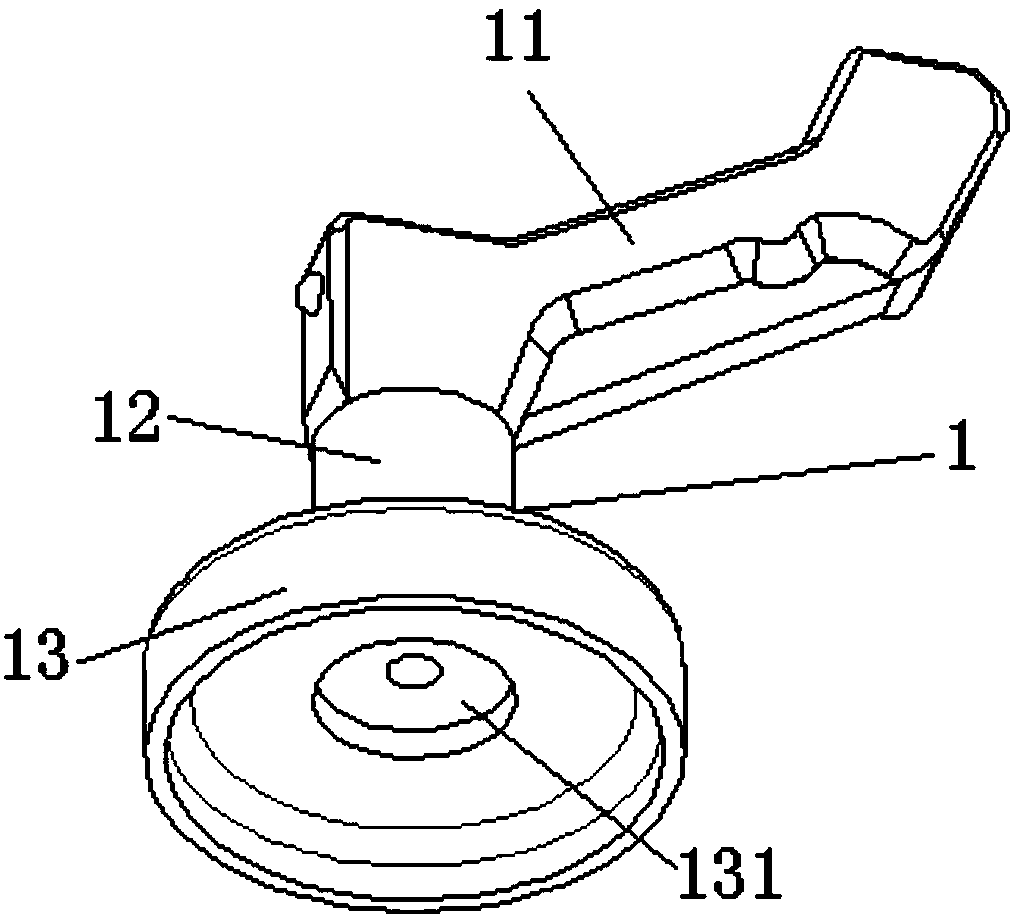

[0037] Such as Figure 1 to Figure 3 As shown, an environmentally friendly plastic solid-sealed pole includes a contact 1, an environmentally friendly plastic shell 2, a vacuum interrupter 3, and a buffer layer 4; the connection between the contact 1 and the vacuum interrupter 3 can be screw 5 It can also be connected by welding (electrical connection). After the contact 1 is connected with the vacuum interrupter 3, it is covered with a layer of buffer layer 4. After it is put into the mold, it is injected with molten environmentally friendly thermoplastic material. After cooling, it forms a solid with a fixed upper end and a movable lower end. Seal pole.

[0038] Such as figure 1 , Figure 4 As shown, the vacuum interrupter 3 includes a static contact 31, a stainless steel layer 32, a porcelain bottle 33, a stainless steel layer 34, and a moving contact 35; the static cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com