Tussah silk interwoven mat and weaving process method

A process method and technology of tussah silk, applied in textiles and papermaking, fabrics, textiles, etc., can solve the needs of difficult modern life, easy deformation, poor dimensional stability and other problems, to promote blood circulation, improve sleep quality, elegant and luxurious. effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Selection of raw materials

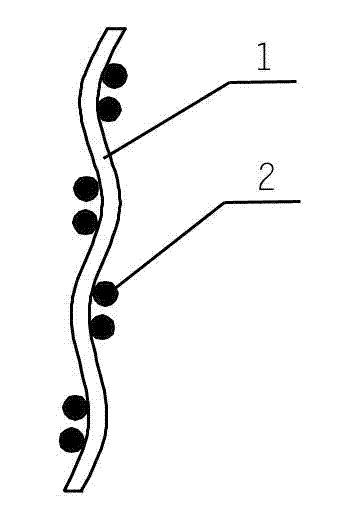

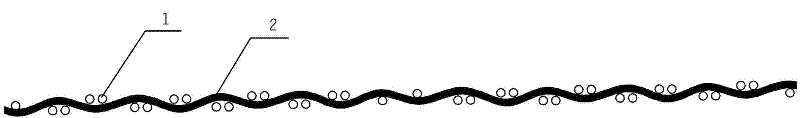

[0032] Tussah silk twisted warp yarn 1: 125dtex / 2, the twist is 7 S twists per centimeter, 3 strands are combined after steaming and finalized, and twisted again, the twist is 1.57 Z twists per centimeter;

[0033] Combed cotton twisted weft yarn 2: 107.62 dtex / 2, the twist is 7 S twists per centimeter, 3 strands are combined after steaming and finalized, and twisted again, the twist is 2.36 Z twists per centimeter;

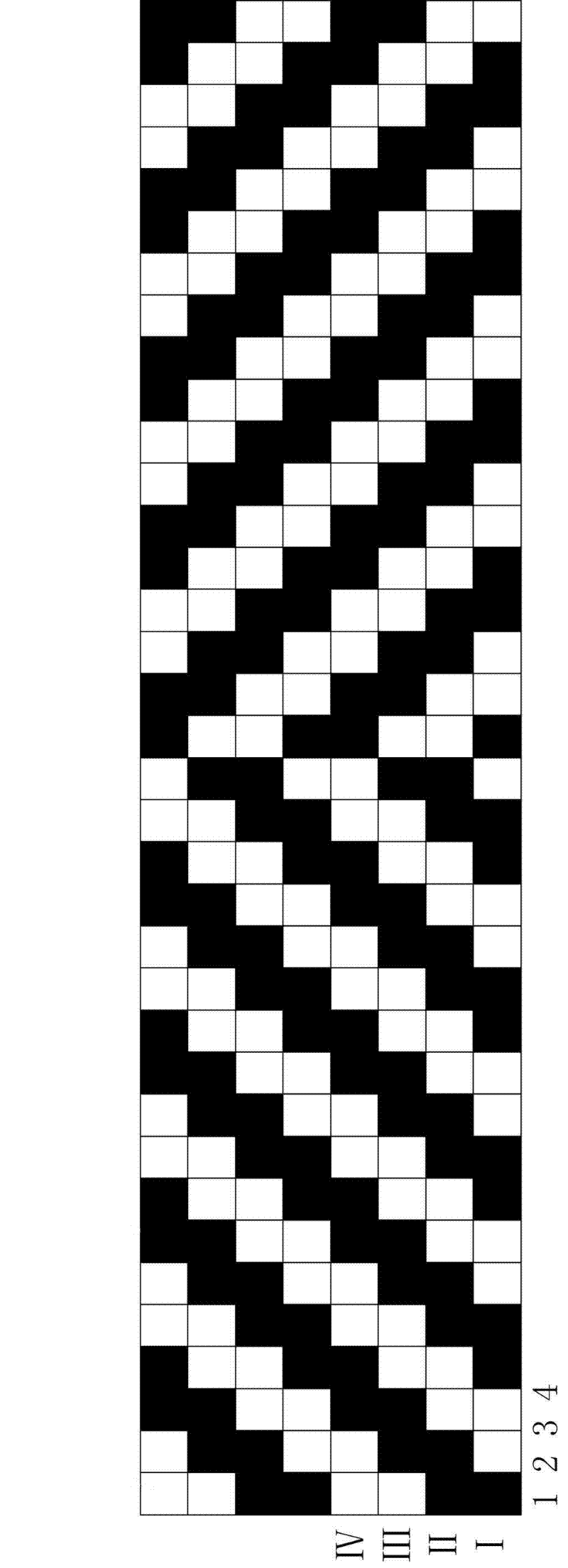

[0034] (2) Organizational structure: 2 / 2 mountain-shaped twill;

[0035] (3) Physical indicators of finished fabrics:

[0036] The warp density is 260 threads / 10cm, and the weft density is 220 threads / 10cm.

[0037] The weaving process method of above-mentioned tussah silk interwoven summer mat is:

[0038] (1) Warp preparation process

[0039] Select 125dtex / 2 tussah spun yarn, twist the yarn after foaming and winding according to the conventional method, the twist is 7 S twists per centimeter, and parallel the silk ...

Embodiment 2

[0049] (1) Selection of raw materials

[0050] Tussah silk twisted warp yarn 1: 187.5dtex / 2 tussah silk yarn twisted, the twist is 9 S twists per centimeter, 3 strands are combined after steaming and finalized, and twisted again, the twist is 1.57 Z twists per centimeter;

[0051] Combed cotton twisted weft yarn 2: 138.11 dtex / 2, the twist is 9 S twists per centimeter, 3 strands are combined after steaming and finalized, and twisted again, the twist is 2.36 Z twists per centimeter;

[0052] (2) The organizational structure is the same as in Example 1;

[0053] (3) Physical indicators of finished fabrics:

[0054] The warp density is 240 threads / 10cm, and the weft density is 200 threads / 10cm.

[0055] The weaving process of the above-mentioned tussah silk interwoven summer mat:

[0056] (1) Warp preparation process:

[0057] Select 187.5dtex / 2 tussah spun yarn with a twist of 9 S twists per centimeter. After steaming, the silks are paralleled. The combined yarns are 3 str...

Embodiment 3

[0063] (1) Selection of raw materials

[0064]Tussah silk twisted warp yarn 1: 250dtex / 2 tussah silk yarn twisted, the twist is 12 S twists per centimeter, 3 strands are combined after steaming and shaped, and twisted again, the twist is 1.57 Z twists per centimeter;

[0065] Combed cotton twisted weft yarn 2: 168.6dtex / 2 combed cotton yarn twisted, the twist is 12 S-direction twists per centimeter, 3 strands are combined after steaming and finalized, and twisted again, the twist is 2.36 Z-direction twists per centimeter ;

[0066] (2) organizational structure: same as embodiment 1;

[0067] (3) Physical indicators of finished fabrics:

[0068] The warp density is 200 threads / 10cm, and the weft density is 180 threads / 10cm.

[0069] The weaving process of the above-mentioned tussah silk interwoven summer mat:

[0070] (1) Warp preparation process:

[0071] Select 250dtex / 2 tussah spun yarn for twisting, the twist is 12 S-direction twists per centimeter, steamed and parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com