Method for constructing functionalized surface and interface by polydopamine coating layer

A technology of polydopamine and functionalization, which is applied in the direction of coatings, types of packaging items, special packaging items, etc., can solve the problems that the dopamine content does not reach the ideal ratio, and the functional groups are difficult to combine, so as to achieve good modification effect and high density. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

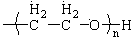

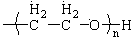

[0031] Preparation of polydopamine coating: (1) prepare fresh dopamine aqueous solution; (2) immerse the substrate to be modified into freshly prepared dopamine aqueous solution, dopamine automatic polymerization time is 15~24h, temperature is 15~35℃ . (3) Take out the substrate to be modified, rinse the dopamine and polydopamine that are not firmly bound to the surface of the substrate with a large amount of distilled water, and let it dry naturally at room temperature.

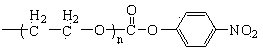

[0032] The preparation of functional polymers containing active ester groups was carried out by reference method (Macromolecular Bioscience 2012, 12:979-985). Its reaction process is as follows:

[0033]

[0034] Dissolve the polymerizable monomers containing active ester groups, phosphorylcholine groups (PC), and polyethylene glycol (PEG) in absolute ethanol according to the designed ratio, add them to the three-necked flask, blow nitrogen to remove oxygen, and add AIBN initiators perform free radical ...

Embodiment 1

[0037] Polydopamine coating is formed on the surface of polytetrafluoroethylene (PTFE) substrate: configure Tris-HCl dopamine buffer solution with a concentration of 2mg / ml pH=8.5, immerse the PTFE substrate with a length of 2cm×2cm into the above solution, and Dopamine was auto-adhesively polymerized at 29°C for 24 hours. After the film base was taken out, it was rinsed with distilled water for 5 times and dried naturally to obtain a polydopamine coating. The dynamic contact angle was measured, and the average advancing angle was 61 ± 5°, and the average receding angle was 15 ± 2°.

Embodiment 2

[0039] Form a polydopamine coating on the surface of a polycarbonate (PC) substrate: configure a Tris-HCl dopamine buffer solution with a concentration of 2mg / ml pH=8.5, and immerse a PC sheet substrate with a length of 2cm×2cm into the above solution, at 32 The dopamine was auto-adhesively polymerized at ℃ for 24 hours. After taking out the film base, it was rinsed with distilled water for 8 times and dried naturally to obtain a polydopamine coating. Determination of the dynamic contact angle ( figure 1 ), the average advancing angle was 58 ± 5°, and the average retreating angle was 11 ± 2°. After heating in hot water at 90℃ for 3h, the dynamic contact angle did not change significantly. X-ray photoelectron spectroscopy showed that the characteristic peak of N element appeared after dopamine was coated on the PC substrate ( figure 2 ), proving the formation of a polydopamine layer on the surface of the PC sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com