PVC compound heat stabilizer prepared from magnesium/aluminum rare-earth hydrotalcite and application thereof

A technology of compound heat stabilizer and hydrotalcite, applied in the field of material application technology development, can solve the problems of toxicity, poor coloring, expensive and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

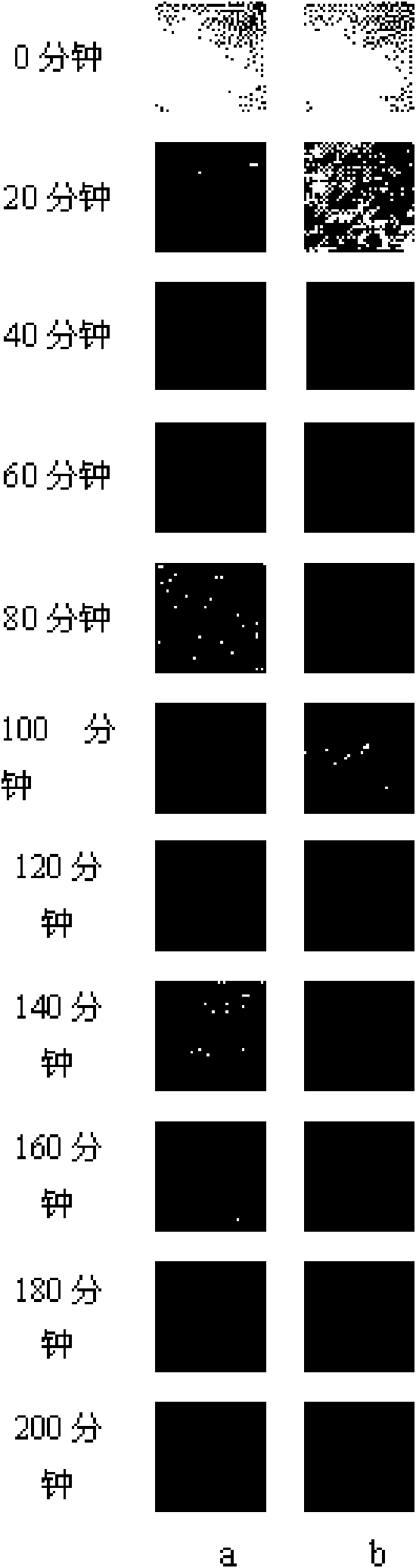

Image

Examples

Embodiment 1

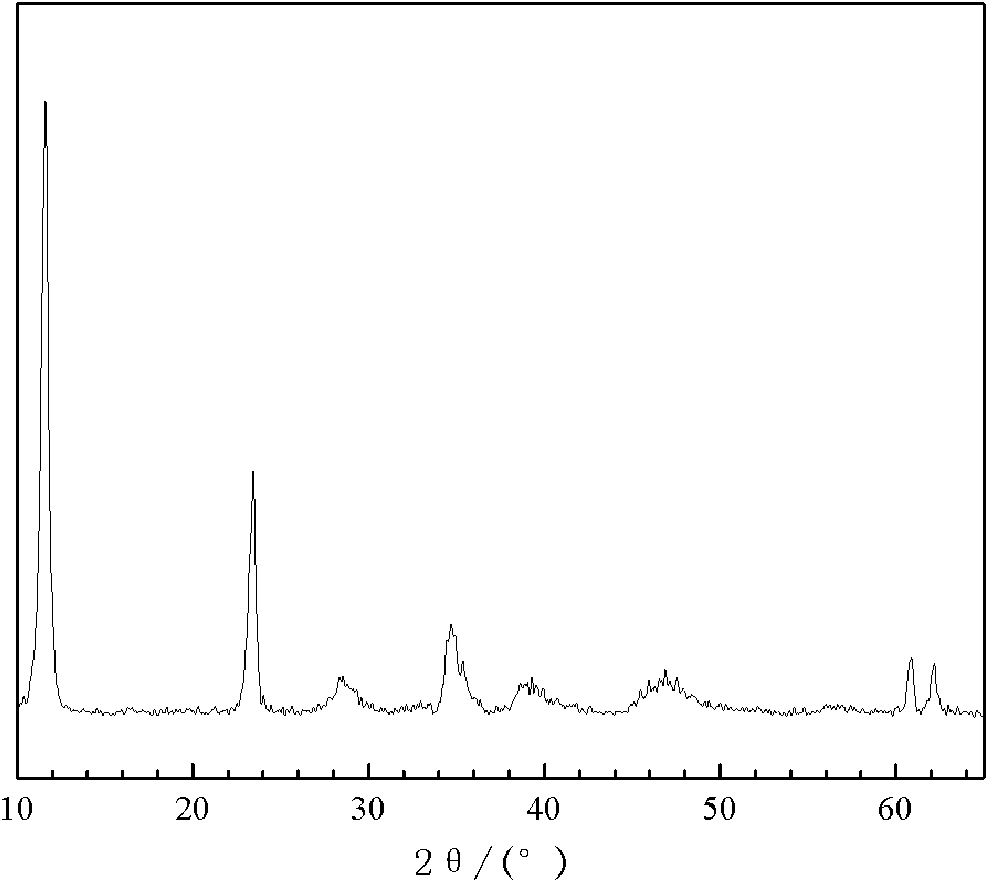

[0049] Magnesium aluminum cerium hydrotalcite (molar ratio: M 2+ / M 3+ =2:1, Ce 3+ / M 3+ =0.025) preparation and modification

[0050] Weigh 12.32gMgSO 4 ·7H 2 O (0.050moL), 8.12gAl 2 (SO 4 ) 3 18H 2 O(0.012moL), 0.271gCe(NO 3 ) 3 ·6H 2 O (0.000625moL), add 40mL deionized water after mixing; weigh 1.325gNa 2 CO 3 (0.013moL) and 6.0gNaOH (0.150moL), after mixing, add 40mL of deionized water; add the above two solutions dropwise to 30mL of deionized water, keep the pH value between 11 and 12, and stir the reaction at 85°C After the dropwise addition, continue to stir for 2 hours, then age at 65° C. for 20 hours, filter, and wash to pH=7 to obtain a magnesium aluminum hydrotalcite filter cake (the moisture content of the wet filter cake is about 82%). Add water in the wet filter cake, water / wet filter cake mass ratio is 50: 1, heat up to 80 ℃, add the modifying agent that accounts for 2% of wet filter cake mass (the modifying agent dissolves titanate in ethylene gly...

Embodiment 2

[0052] According to the method of embodiment 1, the molar ratio obtained is M 2+ / M 3+ =2:1, Ce 3+ / M 3+ =0.075 magnesium aluminum cerium hydrotalcite.

Embodiment 3

[0054] According to the method of embodiment 1, the molar ratio obtained is M 2+ / M 3+ = 3:1, Ce 3+ / M 3+ =0.025 magnesium aluminum cerium hydrotalcite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com