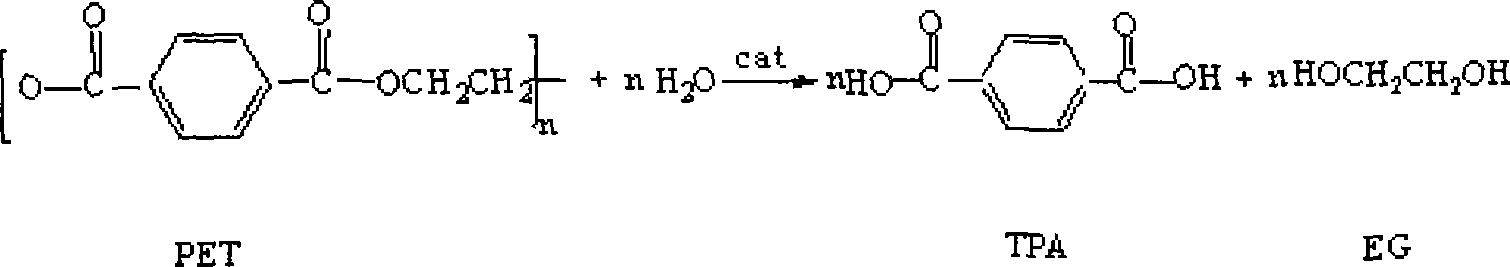

Catalytic depolymerization process of poly-glycol telephthalate unde microwave irradiation

A technology of polyethylene terephthalate and microwave radiation, which is applied in chemical instruments and methods, preparation of carboxylate/lactone, organic chemistry, etc., can solve problems such as harsh reaction conditions, and achieve mild reaction conditions, The effect of reducing the activation energy and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0026] Put PET pellets, water, and magnesium oxide catalyst into the reactor, the weight ratio of PET and water is 1:10, and the weight ratio of magnesium oxide catalyst accounts for 1.5%; the reaction temperature is set to 200°C, the reaction pressure is 1.2MPa, and the microwave power is 250W, after depolymerization for 150min, cool for 20min; filter the depolymerization product, wash the solid with a small amount of deionized water, dry the solid to constant weight; distill the filtrate to obtain the EG product; dissolve the crude TPA with 0.5mol / L NaOH solution, add Diluted with hydrochloric acid equivalent to sodium ions, filtered, washed with deionized water to remove NaCl aqueous solution, obtained pure TPA solid, dried to obtain a white refined TPA solid product, and the PET depolymerization rate reached 88.5%.

experiment example 2

[0028] Put PET particles, water, and zinc oxide catalyst into the reactor, the weight ratio of PET and water is 1:6, and the weight ratio of zinc oxide catalyst is 0.7%; set the reaction temperature to 200°C, the reaction pressure to 1.0MPa, and the microwave power to 250W, after depolymerization for 120min, cool for 20min; filter the depolymerization product, wash the solid with a small amount of deionized water, dry the solid to constant weight; distill the filtrate to obtain the EG product; dissolve the crude TPA with 0.5mol / L NaOH solution, add Hydrochloric acid equivalent to sodium ions, filtered, washed with deionized water to remove the NaCl aqueous solution, obtained a pure TPA solid, dried to obtain a white refined TPA solid product, and the PET depolymerization rate reached 82.4%.

experiment example 3

[0030] Put PET pellets, water, and manganese dioxide catalyst into the reactor, the weight ratio of PET and water is 1:12, and the weight ratio of manganese dioxide catalyst is 1.0%; set the reaction temperature to 180°C, the reaction pressure to 1.0MPa, microwave The power is 250W, after depolymerization for 100min, cool for 20min; filter the depolymerization product, wash the solid with a small amount of deionized water, dry the solid to constant weight; distill the filtrate to obtain the EG product; dissolve the crude TPA with 0.5mol / L NaOH solution , adding hydrochloric acid equivalent to sodium ions, filtering, washing with deionized water to remove the NaCl aqueous solution, and obtaining a pure TPA solid, drying to obtain a white refined TPA solid product, and the PET depolymerization rate reaches 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com