Process for producing high-viscosity chips by applying solid-phase viscosifying technology

A solid-phase thickening and slicing technology, applied in the chemical industry, can solve problems such as not being able to meet the needs of the market, and achieve the effects of increasing anti-risk ability, improving physical properties, and inhibiting side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

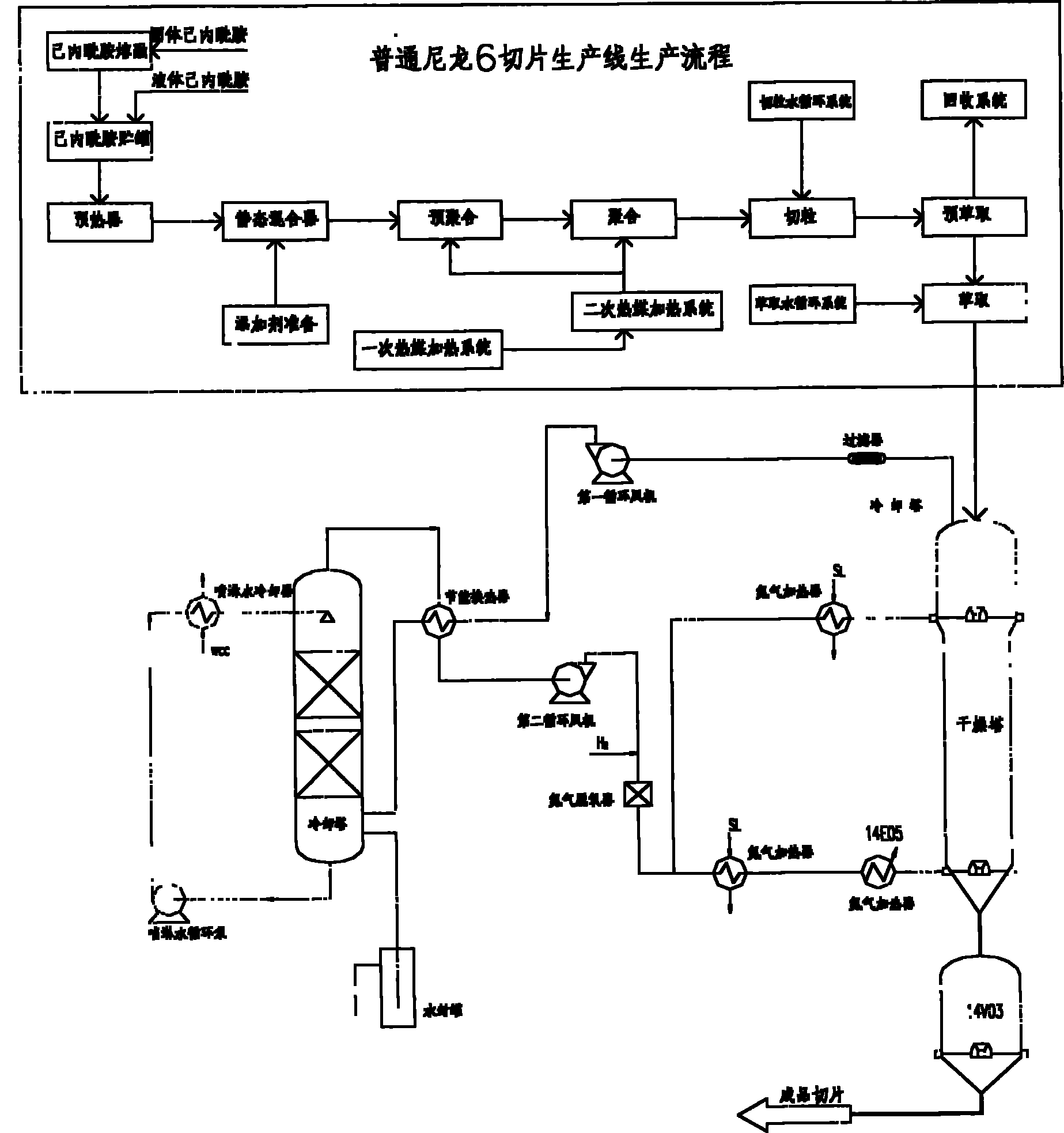

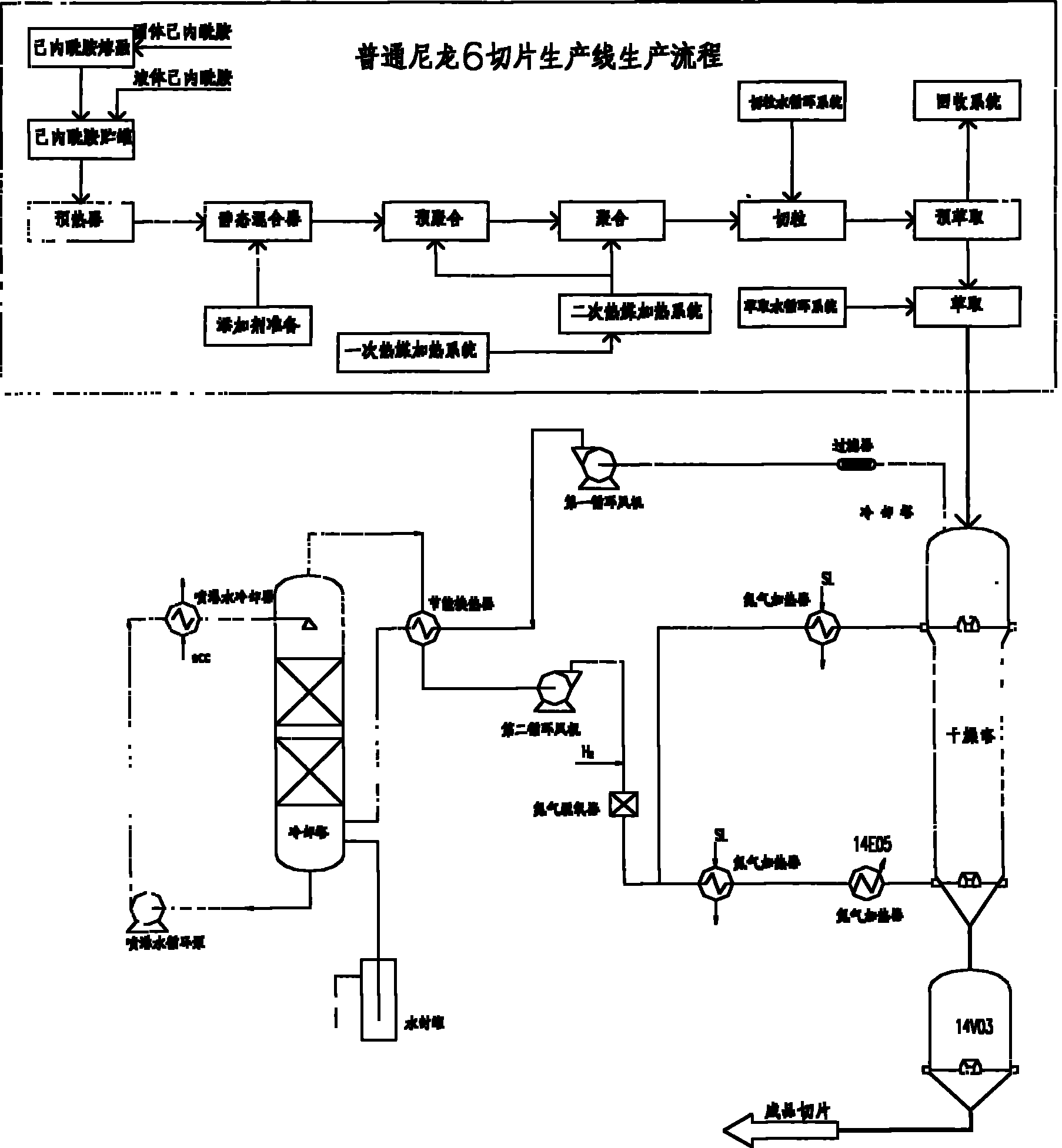

[0025] Embodiment 1, the production process of the solid phase thickening technology used in the ordinary nylon 6 slice production line

[0026] 1) According to the conventional spinning-grade nylon 6 chip production process, the solid caprolactam in the bag is melted in the melting pot, the ring-opening reaction in the pre-polymerization reactor, the addition and polycondensation reaction in the polymerization tower, the pelletizing by the underwater pelletizer, the extraction in the extraction tower, After dehydration by the centrifugal dehydrator, the moisture content is about 8-15%. Nylon 6 slices enter the drying tower;

[0027] 2) Chips flow in the drying tower from top to bottom in a plunger type, and fully contact with nitrogen, and the hot nitrogen for drying is added into the drying tower from the bottom and middle of the tower in two streams;

[0028] The hot nitrogen used for drying comes out from the top of the tower, pressurized by the first nitrogen circulation ...

Embodiment 2

[0032] Embodiment 2, the production process of the solid phase thickening technology used in the ordinary nylon 6 slice production line

[0033] 1) According to the conventional spinning-grade nylon 6 chip production process, the solid caprolactam in the bag is melted in the melting pot, the ring-opening reaction in the pre-polymerization reactor, the addition and polycondensation reaction in the polymerization tower, the pelletizing by the underwater pelletizer, the extraction in the extraction tower, After dehydration by the centrifugal dehydrator, the moisture content is about 8-15%. Nylon 6 slices enter the drying tower.

[0034] 2) The slices in the drying tower flow from top to bottom in a plunger type, and fully contact with nitrogen, and the hot nitrogen for drying is fed into the tower from the bottom and middle of the tower in two streams.

[0035] 3) The hot nitrogen used for drying comes out from the top of the tower, pressurized by the first nitrogen circulation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com