Palladium coordination polymer molecule aggregate catalysis material as well as preparation method and application thereof

A technology for molecular aggregates and catalytic materials, which is applied in the field of palladium coordination polymer molecular aggregate catalytic materials and their preparation, can solve the problems of difficult separation of catalysts and reactants/products, and achieves efficient recyclability and simple preparation technology. Easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

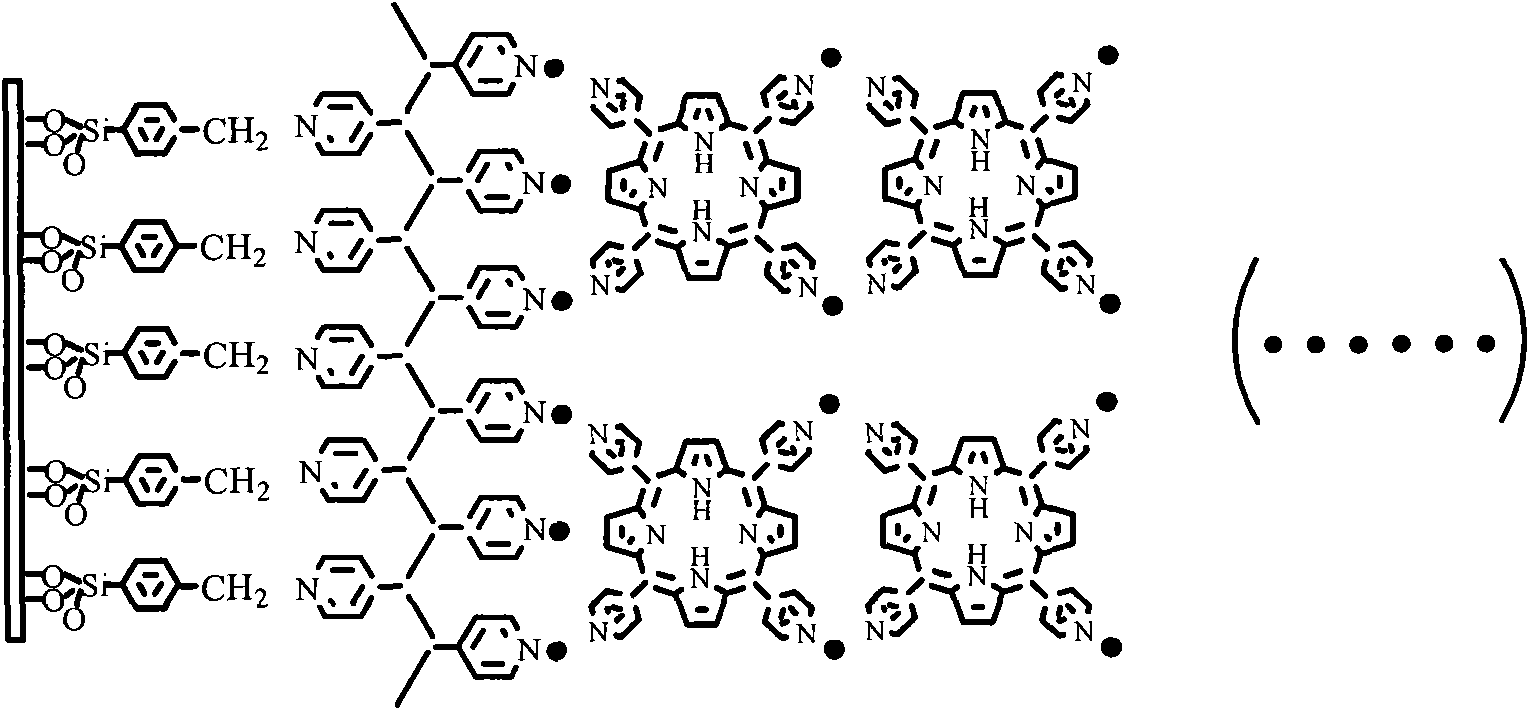

[0053] Using the Langmuir-Blodgett membrane preparation technique, add 0.002M dichloro-2,2'-bipyridine palladium (Pd(en) 2 Cl 2 ) aqueous solution, and then drop about 100 microliters of 0.5mM metal tetrapyridyl porphyrin (MTPyP) chloroform solution at the gas-liquid interface with a micro-syringe, after the chloroform solvent is completely volatilized and the interface coordination reaction is completed (usually required More than 20 minutes), compress the surface until the surface pressure rises to about 20mN / m, keep the surface pressure, use the LB film preparation technology to lift the film, and deposit metal porphyrin-containing palladium coordination polymer molecular aggregation on the clean quartz substrate surface Multilayer films of bulk catalytic material Pd-MTPyP.

Embodiment 2

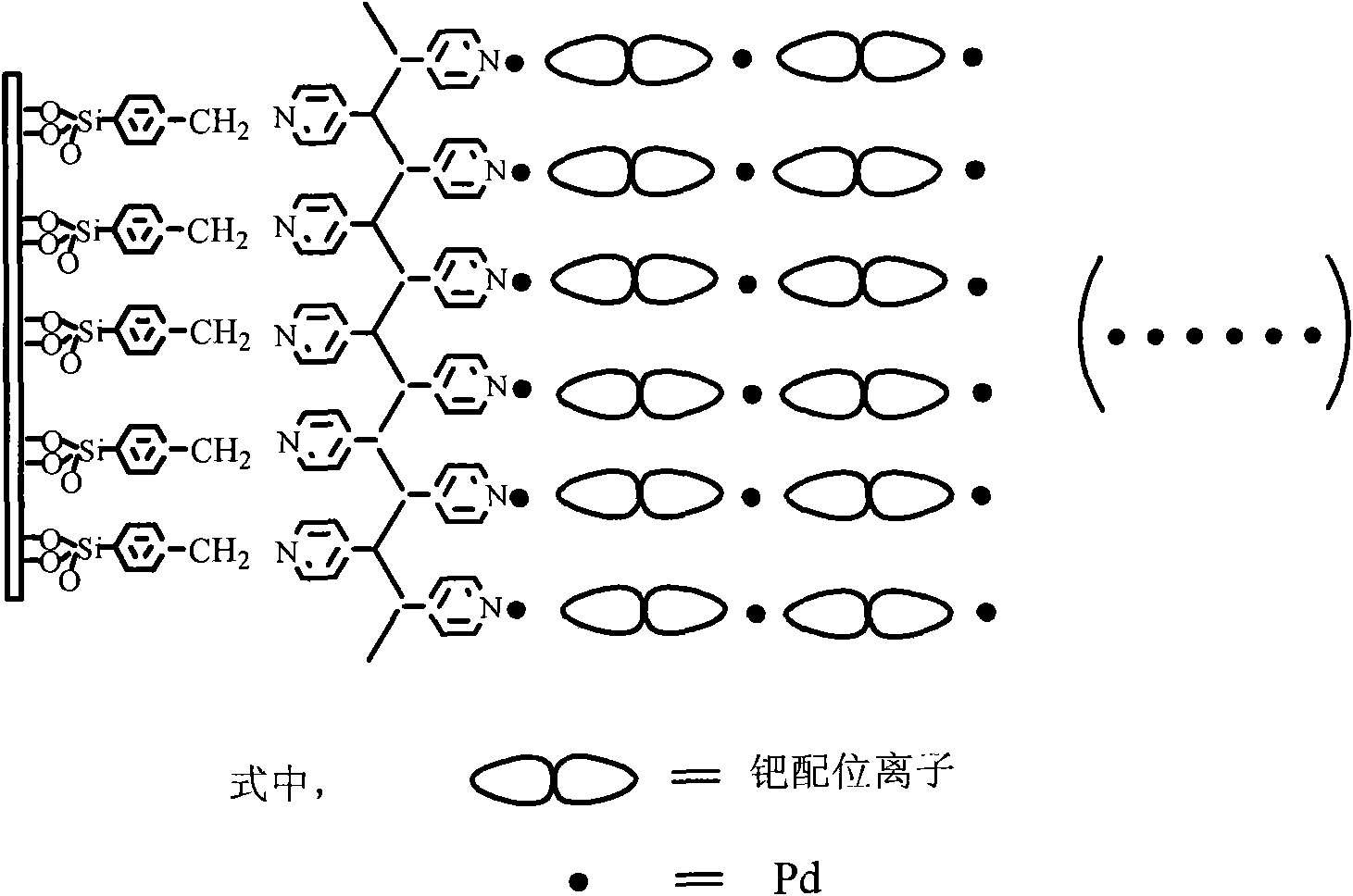

[0055] Using the Langmuir-Blodgett membrane preparation technique, add potassium tetrachloropalladate (KP) containing 0.002M in the cleaned Langmuir tank 2 PdCl 4 ) aqueous solution, then drop about 100 microliters of chloroform solution of 0.5mM polyvinylpyridine (PVP) at the gas-liquid interface with a micro-syringe, after the chloroform solvent is completely volatilized and the interface coordination reaction is completed (usually more than 20 minutes ), compress the surface until the surface pressure rises to about 20mN / m, keep the surface pressure, and use the LB film extraction technology to deposit a multilayer film of palladium coordination polymer molecular aggregate catalytic material Pd-PVP on the surface of a clean glass substrate.

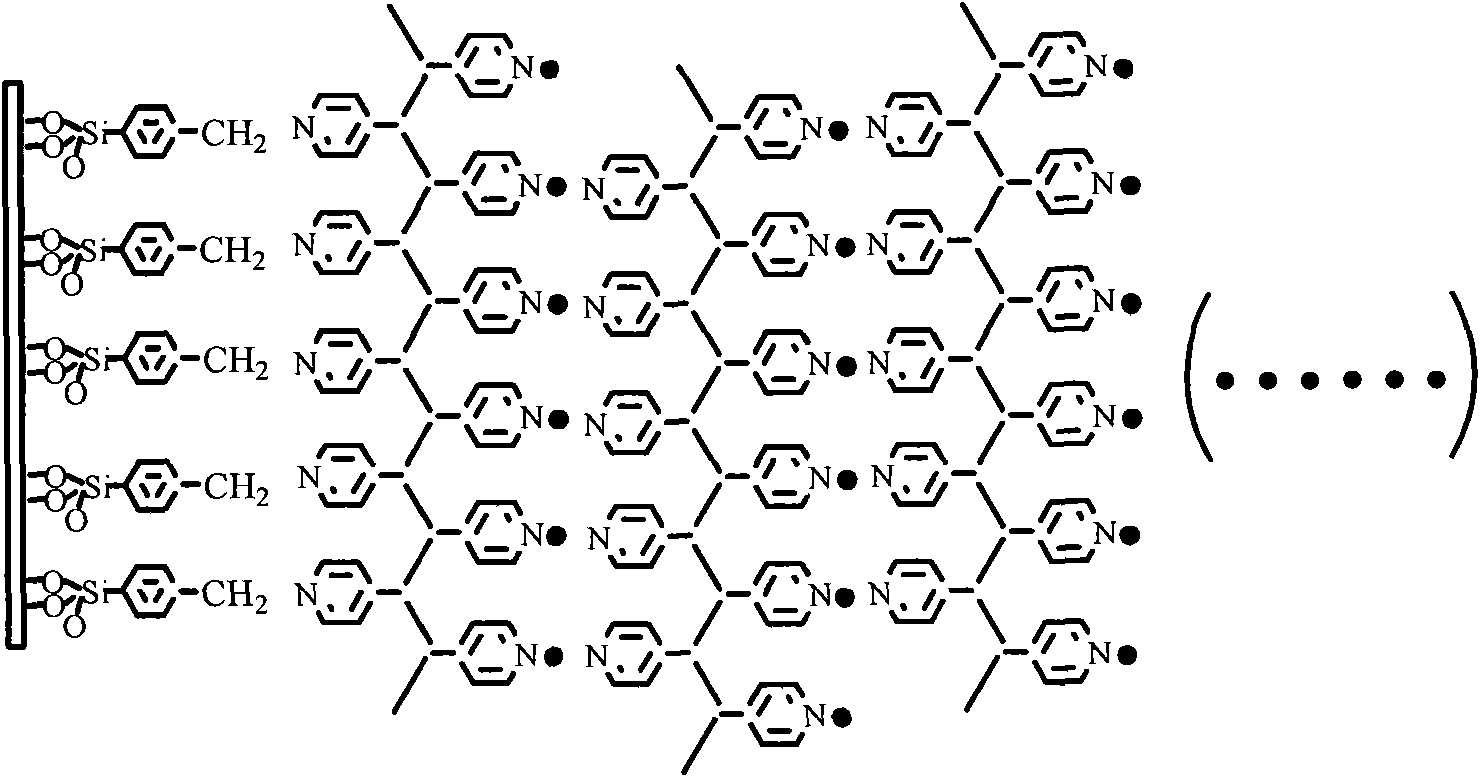

[0056] 2. The three-dimensional molecular aggregate catalytic material of the palladium coordination polymer is directly assembled on the solid surface by using the molecular layer-by-layer assembly technology.

[0057] The preparatio...

Embodiment 3

[0063] A. Preparation of solid substrate: Wash the mica substrate and soak it with 4% sodium hydroxide for 24 hours to obtain a hydroxylated hydrophilic solid substrate, then use 2% chlorobenzylchlorosilane in chloroform or Methanol solution soaking, reacting to form a self-assembled silanized solid substrate modified with an active chlorobenzylchlorosilane monolayer film;

[0064] B. Formation of the polymer layer: the mica substrate is placed in an organic solution of 2mM polyvinylpyridine, heated and refluxed for 10 hours, and a layer of polyvinylpyridine polymer layer is formed on the solid surface, and the residue on the mica substrate is rinsed with methanol polymer;

[0065] C, the preparation of catalytic material: the mica substrate is soaked in 0.002mM potassium tetrachloropalladate (K 2 PdCl 4 ) in the aqueous solution, the palladium coordination ion carries out the coordination reaction with the pyridyl group on the macromolecule, and forms a palladium ion layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com