Electrolyte suitable for silicon-carbon negative electrode lithium ion battery and silicon-carbon negative electrode lithium ion battery

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low discharge platform, high battery impedance, FEC easily decomposed by heat, etc., to achieve inhibition of chemical action, good high and low temperature performance , the effect of reducing the transmission impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

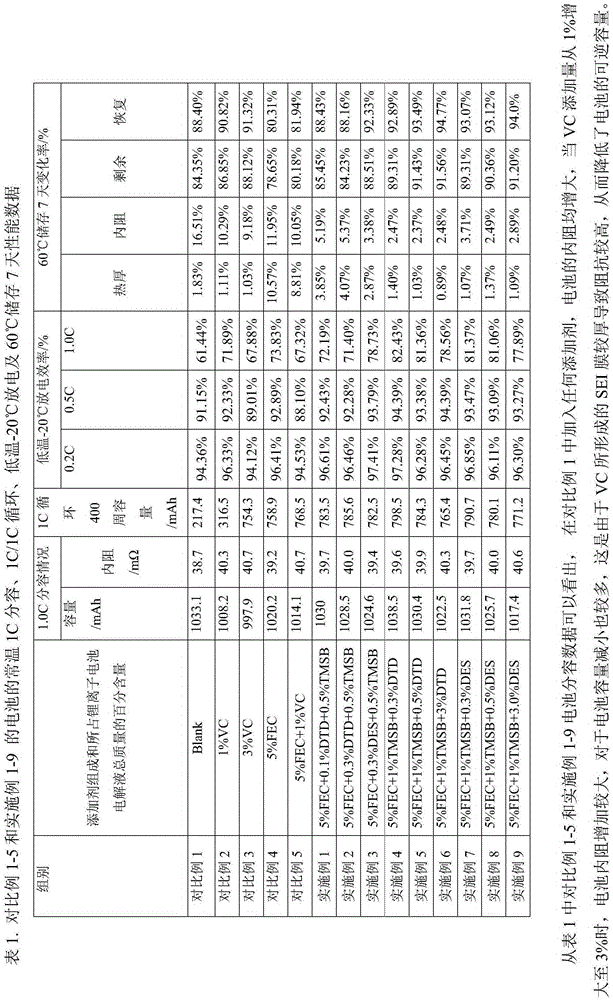

[0045] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 1.

[0046] The lithium-ion battery electrolyte prepared above is injected into the positive electrode active material as lithium cobaltate LiCoO 2 , the negative electrode active material is the Si-C-4A silicon-carbon negative electrode soft-packed lithium-ion battery produced by Shanghai Shanshan Technology Co., Ltd. (the silicon content in the silicon-carbon negative electrode material accounts for 1% to 30%), and the battery after liquid injection After encapsulation, shelving, formation, aging, secondary encapsulation, capacity separation and other processes, a silicon-carbon negative electrode lithium-ion battery is obtained.

Embodiment 2

[0048] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 2.

[0049] The lithium-ion battery electrolyte prepared above is injected into the positive electrode active material as lithium cobaltate LiCoO 2 , the negative electrode active material is the Si-C-4A silicon-carbon negative electrode soft-packed lithium-ion battery produced by Shanghai Shanshan Technology Co., Ltd. (the silicon content in the silicon-carbon negative electrode material accounts for 1% to 30%), and the battery after liquid injection After encapsulation, shelving, formation, aging, secondary encapsulation, capacity separation and other processes, a silicon-carbon negative electrode lithium-ion battery is obtained.

Embodiment 3

[0051] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the lithium-ion battery electrolyte of Example 3.

[0052] The lithium-ion battery electrolyte prepared above is injected into the positive electrode active material as lithium cobaltate LiCoO 2 , the negative electrode active material is the Si-C-4A silicon-carbon negative electrode soft-packed lithium-ion battery produced by Shanghai Shanshan Technology Co., Ltd. (the silicon content in the silicon-carbon negative electrode material accounts for 1% to 30%), and the battery after liquid injection After encapsulation, shelving, formation, aging, secondary encapsulation, capacity separation and other processes, a silicon-carbon negative electrode lithium-ion battery is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com