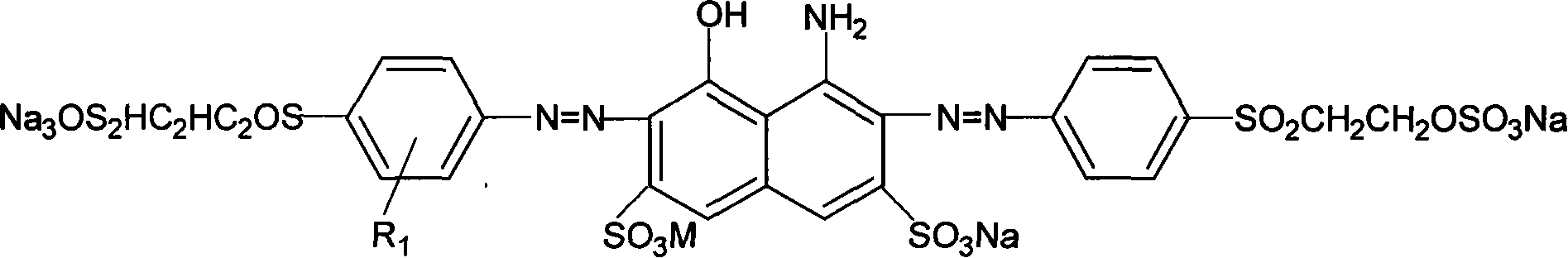

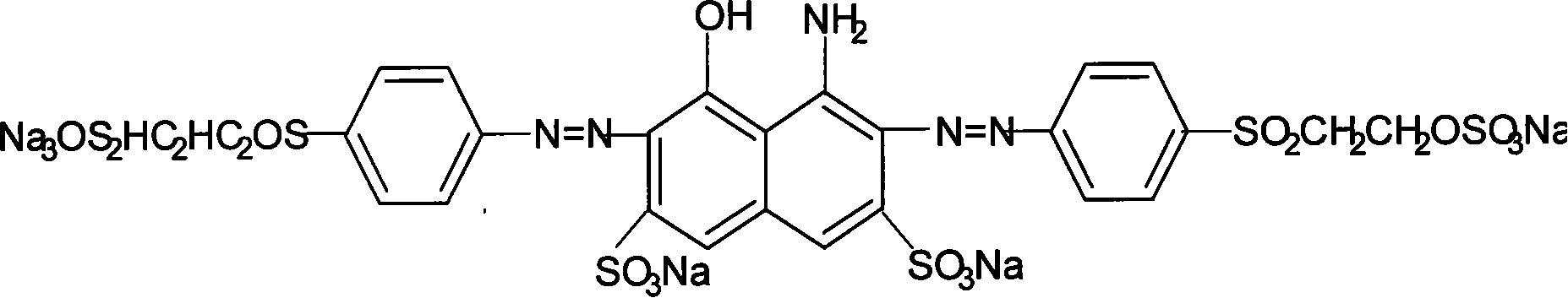

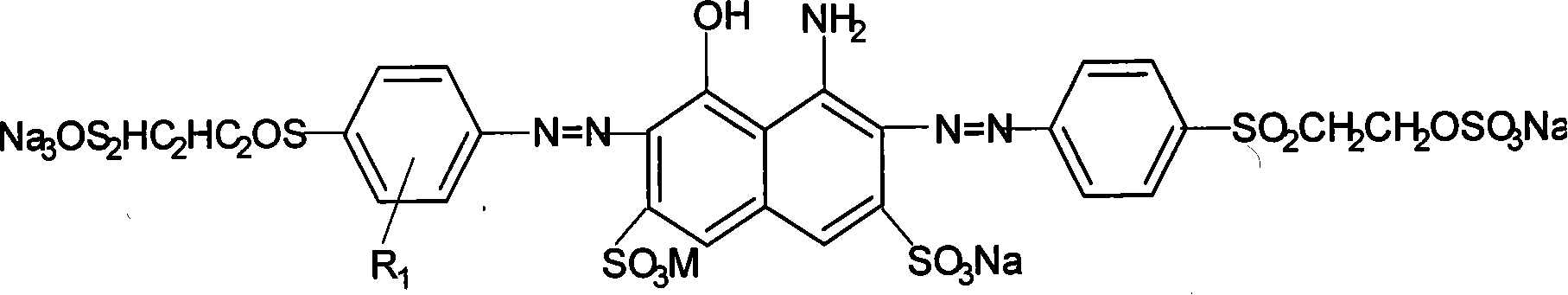

Reactive dark blue RGB diazo dyes and preparation method thereof

A technology of reactive navy blue and azo dyes, applied in azo dyes, reactive dyes, organic dyes, etc., can solve the problems of insufficient monochromatic blackness, low fixation rate, and inability to dye deep black.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Weigh 59 parts of ethyl sulfone sulfate aniline compounds containing sulfonic acid groups or methyl, methoxy, ethyl, ethoxy groups, add an appropriate amount of ice water and beat for 2 hours at 0°C.

[0038] (2) Then add quantitative hydrochloric acid, add 6.9 parts of sodium nitrite, temperature 5-8 ℃, control the blue color of Congo red test paper, KI test paper slightly blue, react for 1 hour after adding sodium nitrate, and eliminate the slight excess of nitrous acid.

[0039] (3) Add 34 parts of H acid to the diazonium salt, under the conditions of 0-15°C, PH=1.3-6.5, the first acid couple and then the base couple to obtain a red light reactive navy blue RGB dye.

Embodiment 2

[0040] Embodiment 2: Adopt the formula of Embodiment 1, couple under the condition of 10-15 ℃, PH=1.3-5.5, obtain a kind of partial blue reactive black S-G.

Embodiment 3

[0042] (1) Weigh 59.5 parts by weight of ethyl sulfone sulfate aniline compound containing sulfonic acid groups or methyl, methoxy, ethyl, ethoxy groups, add appropriate amount of ice water and beat for 2 hours at 0°C.

[0043] (2) Then add quantitative hydrochloric acid, add 6.9 parts of sodium nitrite, temperature 5-8 ℃, control the blue color of Congo red test paper, KI test paper slightly blue, react for 1 hour after adding sodium nitrate, and eliminate the slight excess of nitrous acid.

[0044] (3) Add 34 parts of H acid to the diazonium salt, under the conditions of 10-25°C, PH = 2-6.5, the first acid couple and then the base couple to obtain a red-light reactive blue C.I250.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com