Oil-removing treatment process of oil-containing sludge

A treatment process, oil sludge technology, applied in sludge treatment, water/sludge/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of high treatment cost and low treatment efficiency, and achieve low operating temperature , Lower deoiling temperature, lower equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

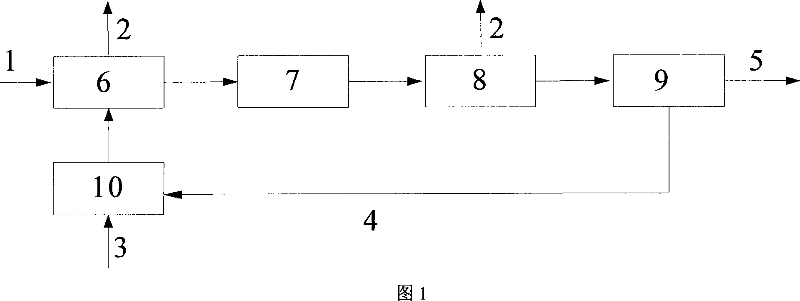

Method used

Image

Examples

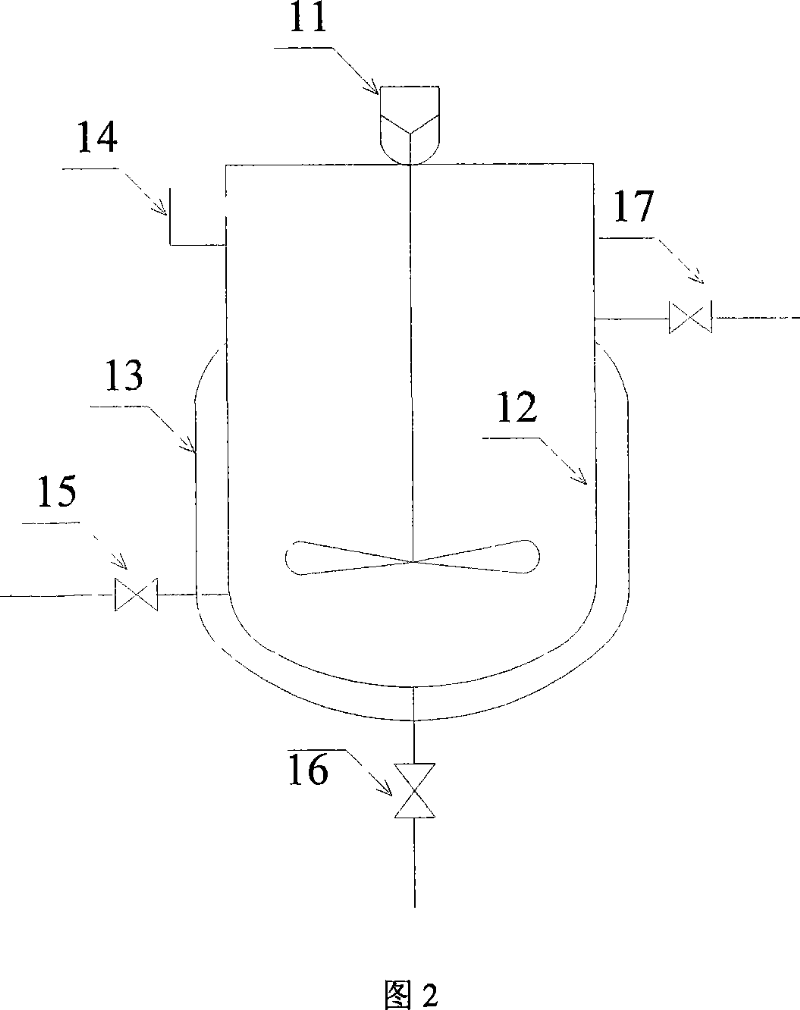

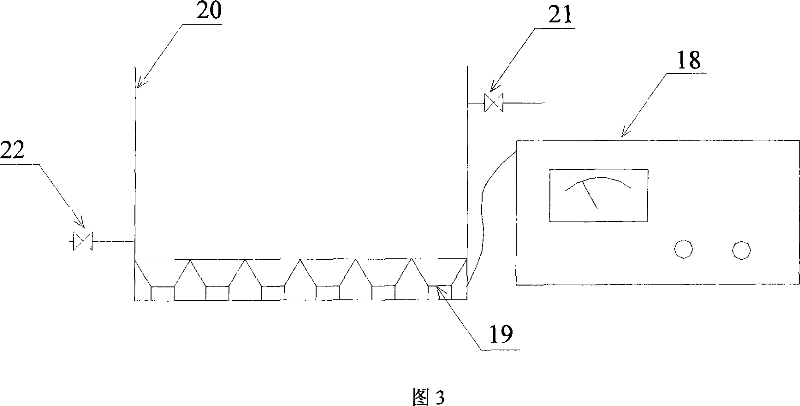

Embodiment 1

[0034] Oily sludge (black, massive) from a sewage station in an oil field, with a water content of 60% and an oil content of 14%. Utilize the specific process of the present invention to deal with: at first the oily sludge is pumped into the preheating conditioning tank (6), and the cleaning liquid that enters the cleaning liquid storage tank (10) is mixed evenly according to the mass ratio of dry mud and water as 1: 32, in Heat while stirring. After the preheating temperature reaches 55°C, the sludge enters the ultrasonic irradiation device (7). The ultrasonic frequency of oily sludge is about 28kHz, and the ultrasonic sound intensity is 6×10 3 w·m -2 The residence time in the ultrasonic reverberation field is 20min. The oily sludge irradiated by ultrasound enters the aeration flotation tank (8), and after 20 minutes of flotation (air flotation gas-liquid ratio 1×10 2 m 3 m -3 ) After that, the dirty oil in the oily sludge is separated from the sludge, and the dirty oil...

Embodiment 2

[0036] Other conditions are the same as in Example 1, but the operating conditions are changed: the preheating temperature is 60° C., the ultrasonic frequency is about 28 kHz, and the ultrasonic sound intensity is 4×10 3 w·m -2 , the ultrasonic irradiation time is 15min, the mass ratio of sludge to cleaning water is 1:32, the air flotation time is 20min, and the gas-liquid ratio is about 2×10 2 m 3 m -3 , the gravity settling time is 3h, and the whole process removes 73% of dirty oil.

Embodiment 3

[0038] Other conditions are the same as in Example 1, but the operating conditions are changed: preheating temperature is 50° C., ultrasonic frequency is about 28 kHz, and ultrasonic sound intensity is 4×10 3 w·m -2 , the ultrasonic irradiation time is 15min, the mass ratio of sludge to cleaning water is 1:64, the air flotation time is 20min, and the gas-liquid ratio is about 2×10 2 m 3 m -3 , the gravity settling time is 3h, and the whole process removes 69% of dirty oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com