A kind of manipulator unloading brick gripper and unloading method

A technology of manipulator and gripper, which is applied in the field of manipulator unloading brick gripper and brick unloading, which can solve the problems of large power stroke, product falling off, deformation, adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the invention.

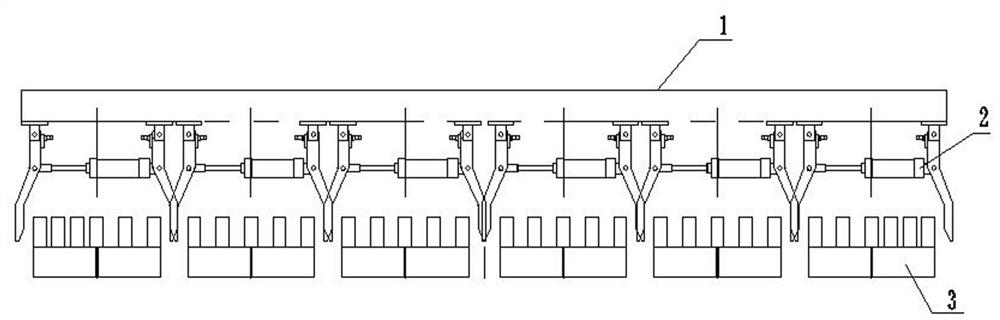

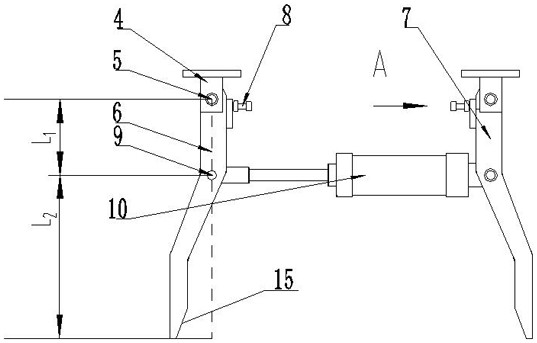

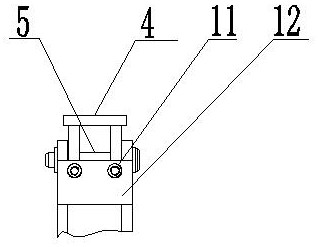

[0030] Referring to the drawings, a manipulator unloading brick gripper, installed on the unloading manipulator, used for the clamping of brick groups 3 on the brick stack, includes a plurality of swing claws arranged on the lower surface of the manipulator hanger 1 according to the brick stack Combination 2. A plurality of swing claw assemblies 2 are sequentially installed on the manipulator in the same direction to form a row of swing claw assemblies. The manipulator is provided with multiple rows of swing claw assemblies. Among the multiple rows of swing claw assemblies, at least two are a pair. They are clamped in two different positions on the same opposite side of the brick group. The swing claw combination 2 includes a swing claw I6, a swing claw II7 and two hinge supports 4. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com