An energy-feeding magnetorheological fluid energy absorber

An energy absorber and magnetorheological fluid technology, applied in the field of actuators, can solve the problems of increased installation space requirements for the complexity of the cost system, difficult application environment for magnetorheological fluid energy absorbers, and bulky energy absorbers, etc. To achieve the effect of compact structure, application cost saving and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

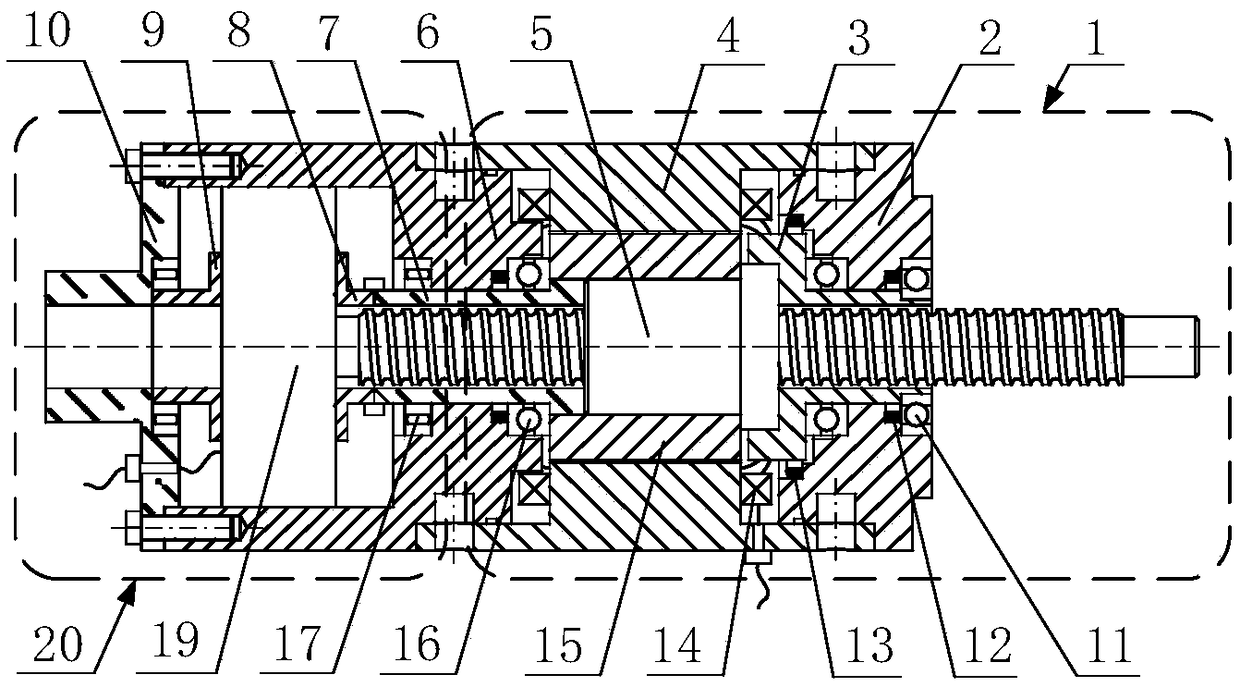

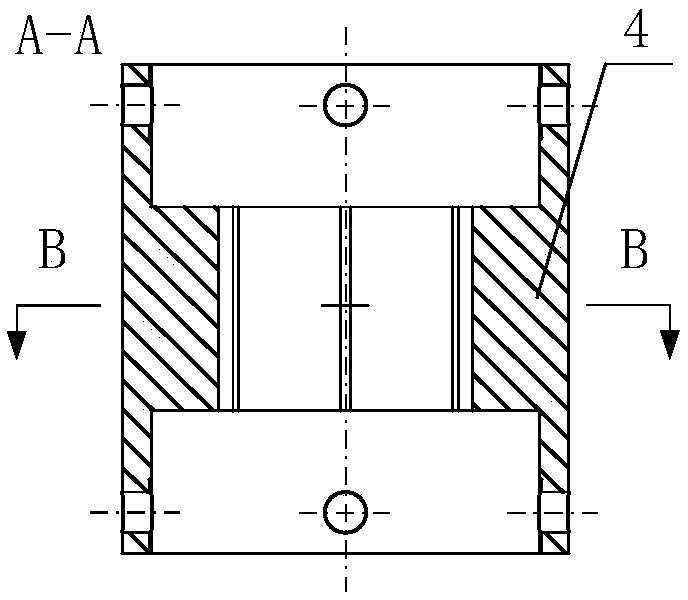

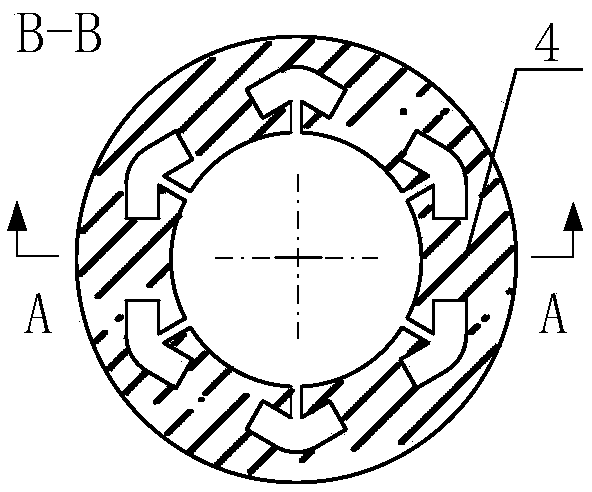

[0058] figure 1 , Figure 2a , Figure 2b , Figure 3a , Figure 3b as well as Figure 4 One embodiment of the invention is shown in the form of:

[0059] Such as figure 1 As shown, the mechanical structure of the energy-feeding magnetorheological fluid energy absorber is composed of a controllable damping force mechanism 1 and an energy-feeding mechanism 20; the controllable damping force mechanism 1 is coaxially assembled by a cylindrical excitation shell 4 and a motion conversion mechanism Composition, the excitation shell 4, the upper end cover 2, and the energy feeding mechanism shell 6 jointly form a closed space filled with magnetorheological fluid, and the closed liquid cavity is filled with magnetorheological fluid, about 82ml; the motion conversion mechanism is composed of the conversion mechanism sleeve 3, The ball screw 5, the excitation rotor 15 and the thrust bearing 16 are coaxially assembled. The outer circumferential surface of the excitation rotor 15 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com