Method and apparatus for operating an internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

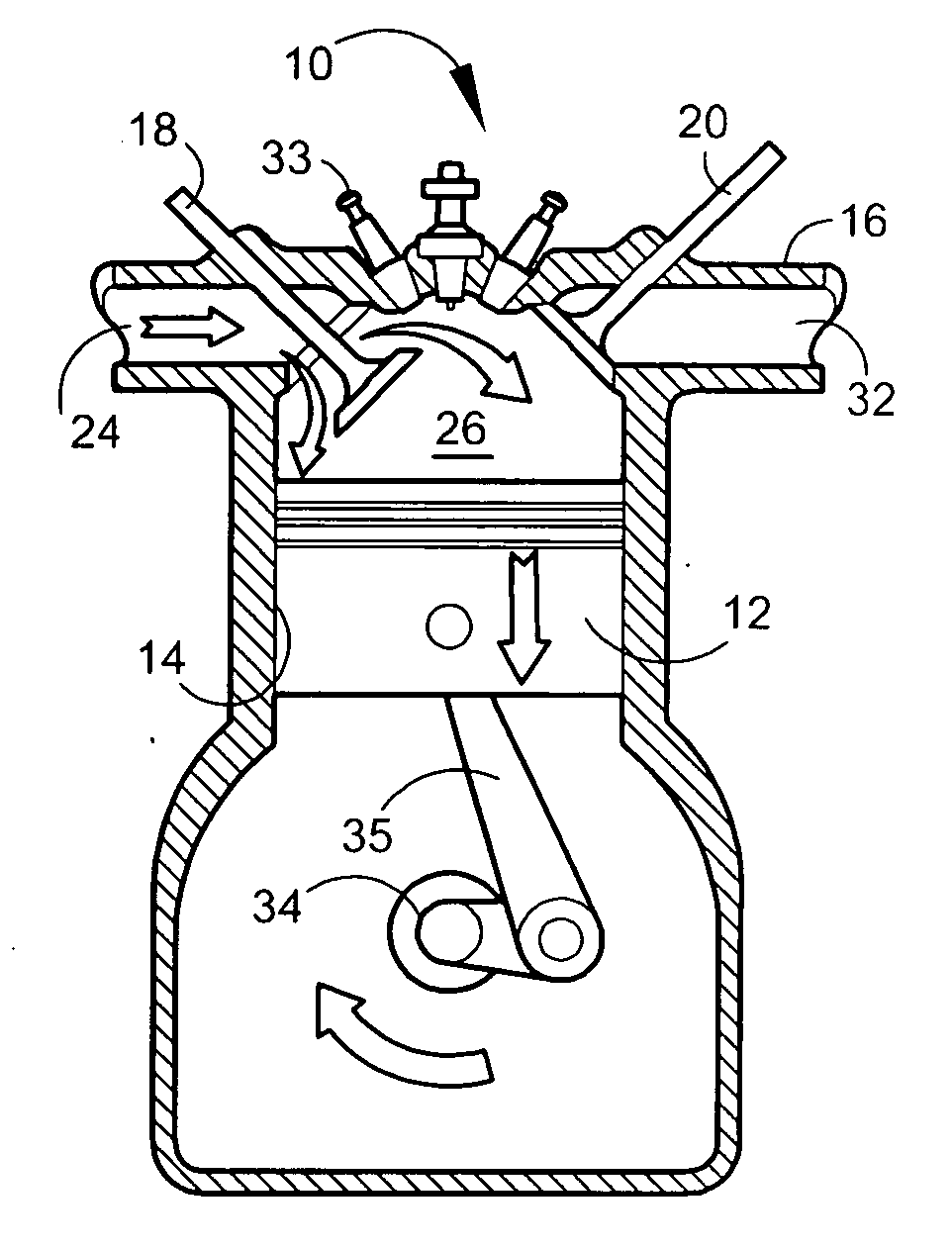

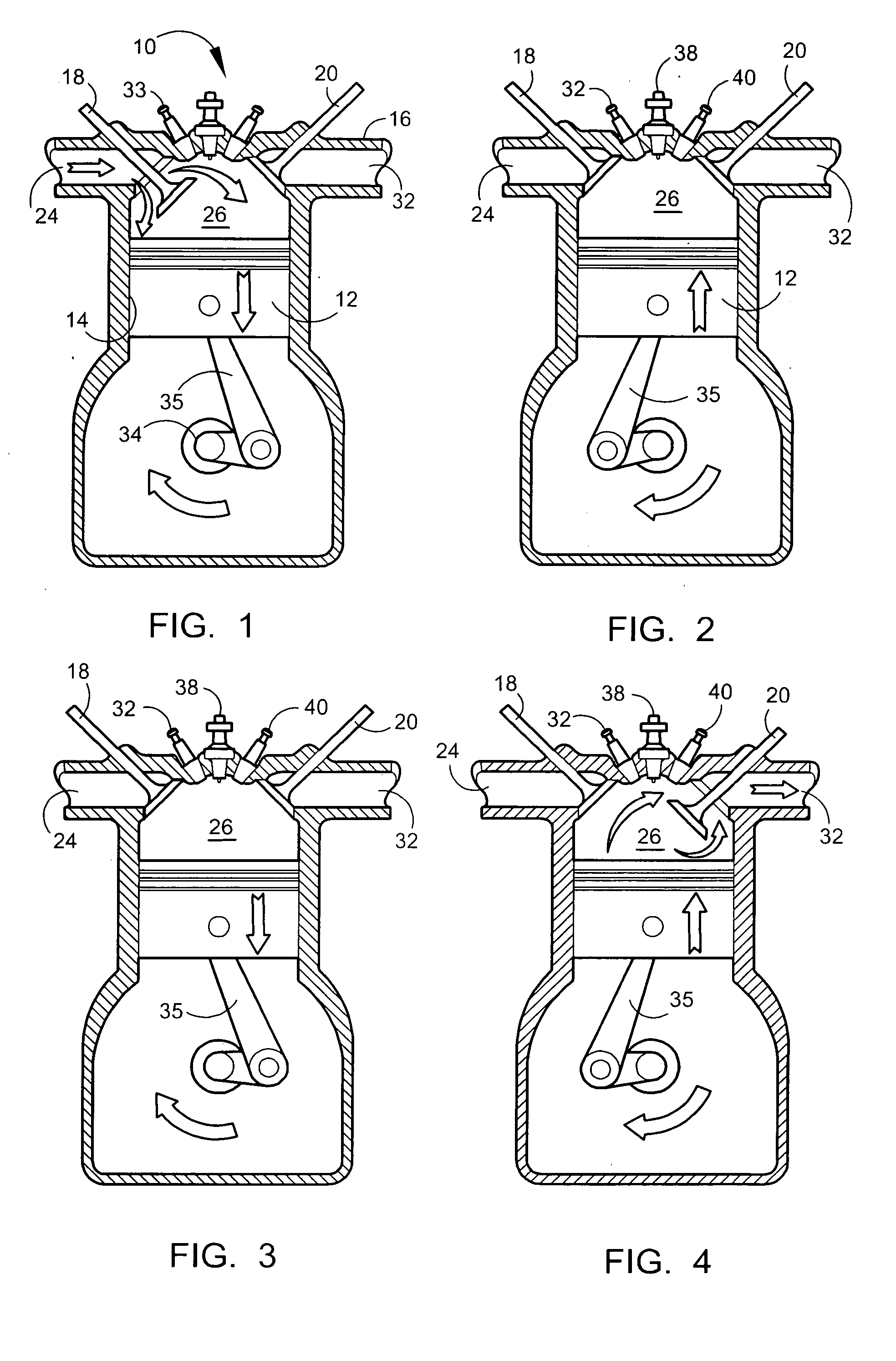

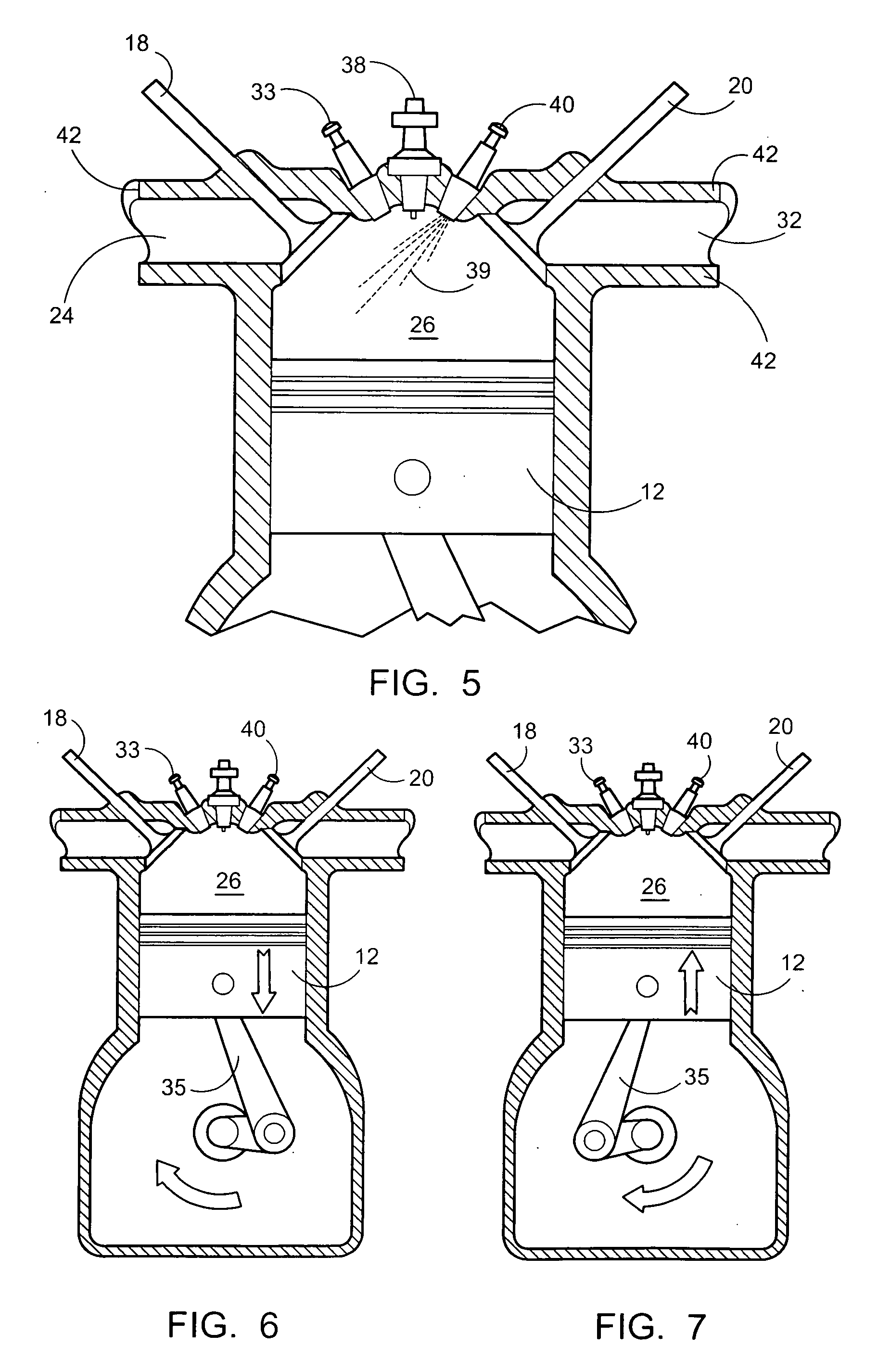

[0058] As shown in FIGS. 1-10 the device employs a novel manner to both cool and increase the power and economy of an internal combustion engine through a recapture of waste heat. In FIG. 1 there is shown a side sliced view of a piston 12 positioned toward an upper position in the cylinder 14 adapted for reciprocated engagement with the piston 12. During a conventional intake stroke of a two or four-cycle engine, the piston 12 moves away from the cylinder head 16 which provides the engagement point for the intake valve 18 and the exhaust valve 20. The intake valve translates to open and close the valve head portion 21 in a seat 22. The intake valve 18 thus controls communication of the intake manifold 24 with the combustion chamber 26. Likewise the exhaust valve 20 translates to engage and disengage a head portion 28 with an exhaust seat 30 and control communication of the combustion chamber 26 with the exhaust manifold 32.

[0059] Conventionally, fuel is communicated to the combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com