Pre-Cooled Liquefaction Process

a liquefaction process and pre-cooled technology, applied in the direction of liquefaction, laminated elements, lighting and heating apparatus, etc., can solve the problems of limiting the applicability of cosub>2 /sub>based cycles, reducing the efficiency of the process, and preventing the removal of required amounts of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

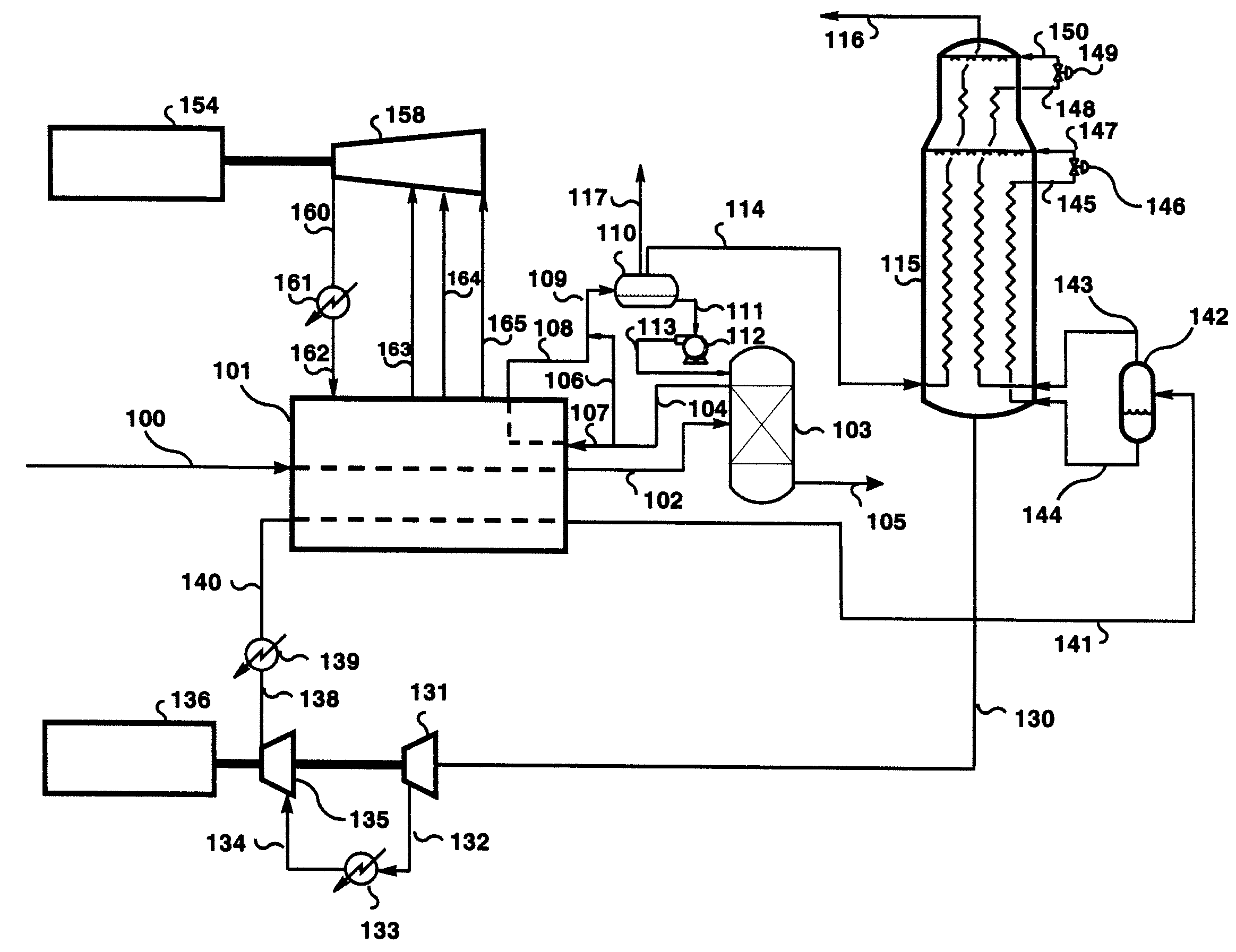

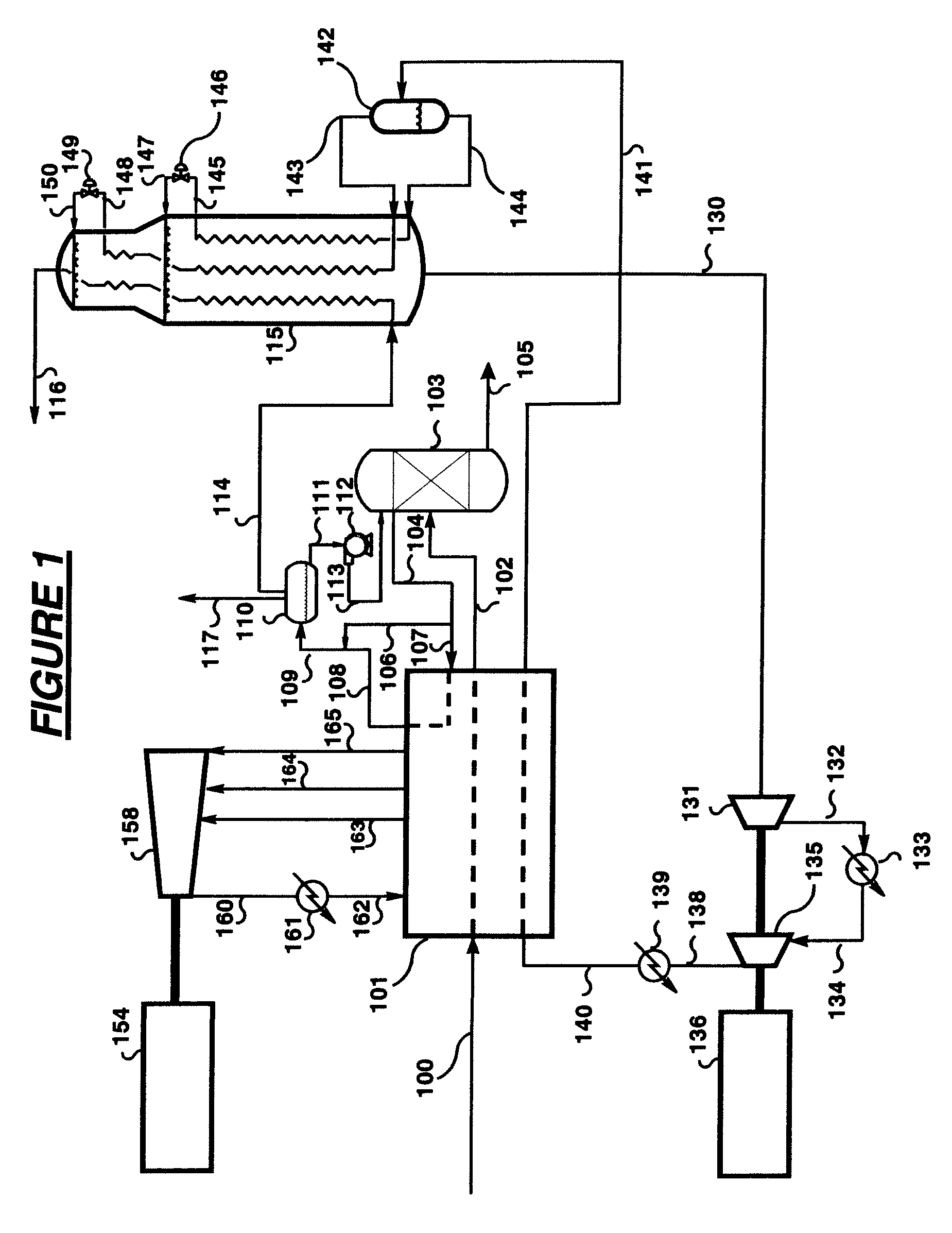

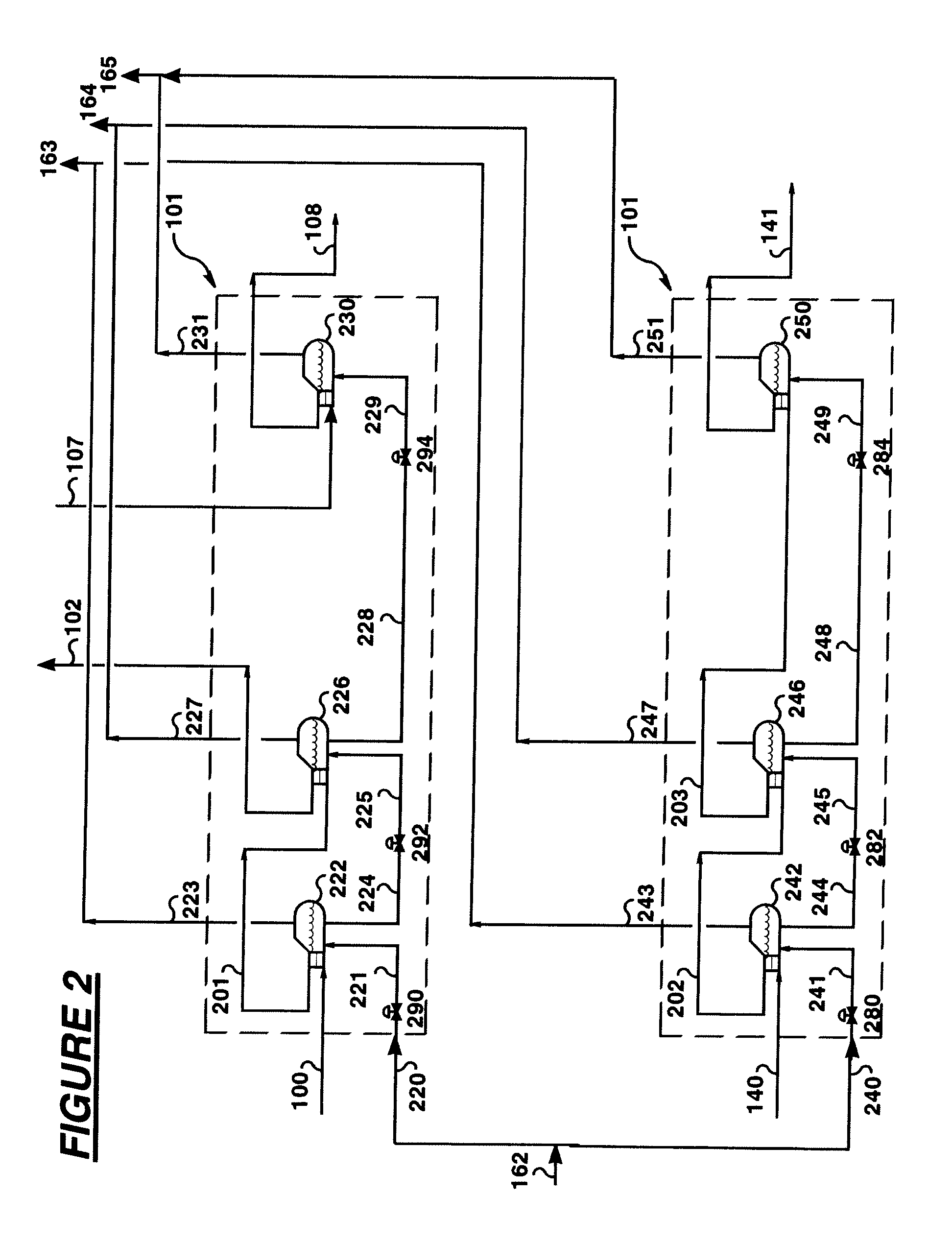

[0071]In this exemplary illustration, a dehydrated natural gas feed stream 100 was liquefied to form LNG using the HFC pre-cooled mixed refrigerant process. The total dehydrated natural gas feed stream 100 entering the pre-cooling section was around 2.39 mmtpa or 301.2 tph. The dehydrated natural gas feed stream 100 from the drier beds (not shown in FIG. 1) entered the HFC cooled evaporator 222 at 15° C. and 68.95 bara where it was cooled to a temperature of −4.06° C. The feed was further cooled in evaporator 226 to a temperature of approximately −24.39° C. after which it was sent to the scrub column 103 as stream 102. The cold reflux stream 111 in the scrub column 103 caused the stripping of the C3+ (propane, butanes, pentane etc.) hydrocarbons from the input stream 102 to yield a vapor overhead stream 104 and a bottoms heavy hydrocarbon stream 105.

[0072]Table 4 summaries the various stream conditions from the exemplary illustration:

TABLE 4Stream102104105Flowlbmol / h38,298.9435,757....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com