Method freezing separating mirabilite by brine solution

A technology for freezing separation and brine solution, which is applied in the field of separation of mirabilite from high awning brine solution, can solve the problems of wasting energy, frequently brushing tanks or cleaning heat exchangers, shortening production cycle, etc., and achieves extended operation cycle, reduced cost and stable process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

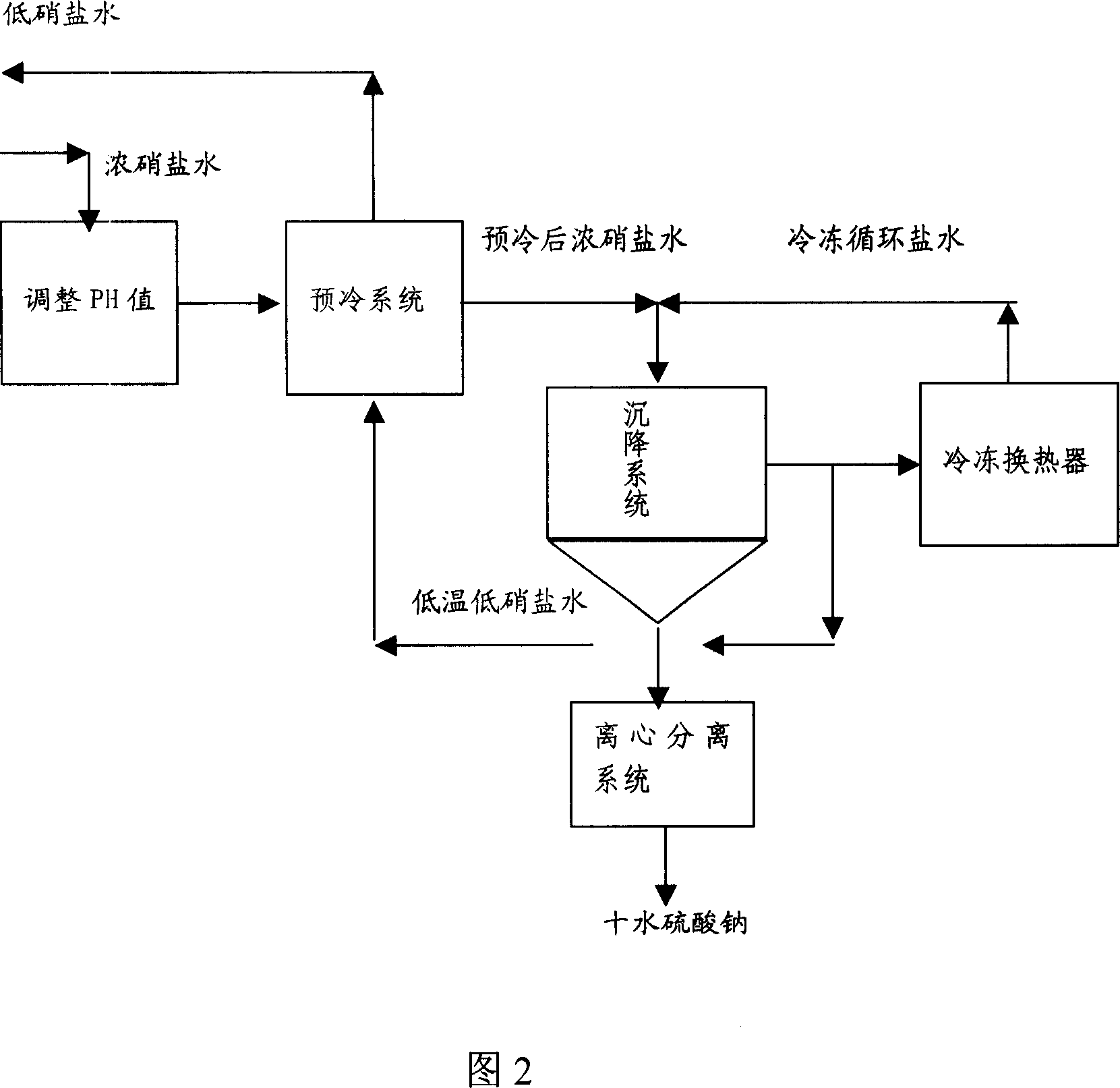

[0017] The method for freezing and separating Glauber's salt of the present invention will be further described below with reference to the drawings and specific embodiments.

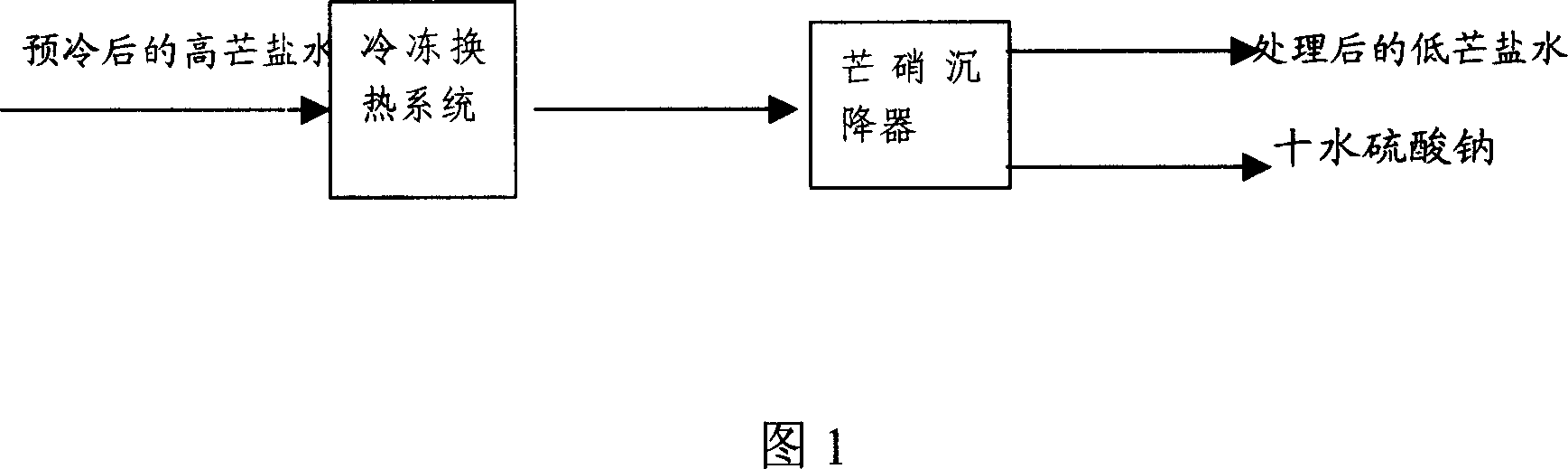

[0018] The process of the method for freezing and separating Glauber's salt with brine solution is shown in Figure 2. The high-salt solution of mirabilite comes from the fields of chlor-alkali, soda ash, salt production, etc., using NF method, MRO method, RO method and other new de-mirabilite processes to obtain sodium sulfate Concentration of saline solution. The specific separation process is:

[0019] 1) After the high-mountain salt solution produced by the removal of sulfate radicals from the nanofiltration membrane, reverse osmosis membrane and modified reverse osmosis membrane technology, first adjust the pH to alkaline with NaOH, and the pH is preferably 9 to 11 , In order to reduce the corrosion of acidic solution to the equipment in the subsequent process;

[0020] 2) The cold brine with a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com