Plant and process for liquefying natural gas

a technology of liquefied natural gas and plant, which is applied in the direction of liquefaction, refrigeration machines, sorption machines, etc., can solve the problems of limited capacity of propane compressors, limited capacity of liquefaction plants, and insufficient suction and discharge outlets of propane compressors in parallel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

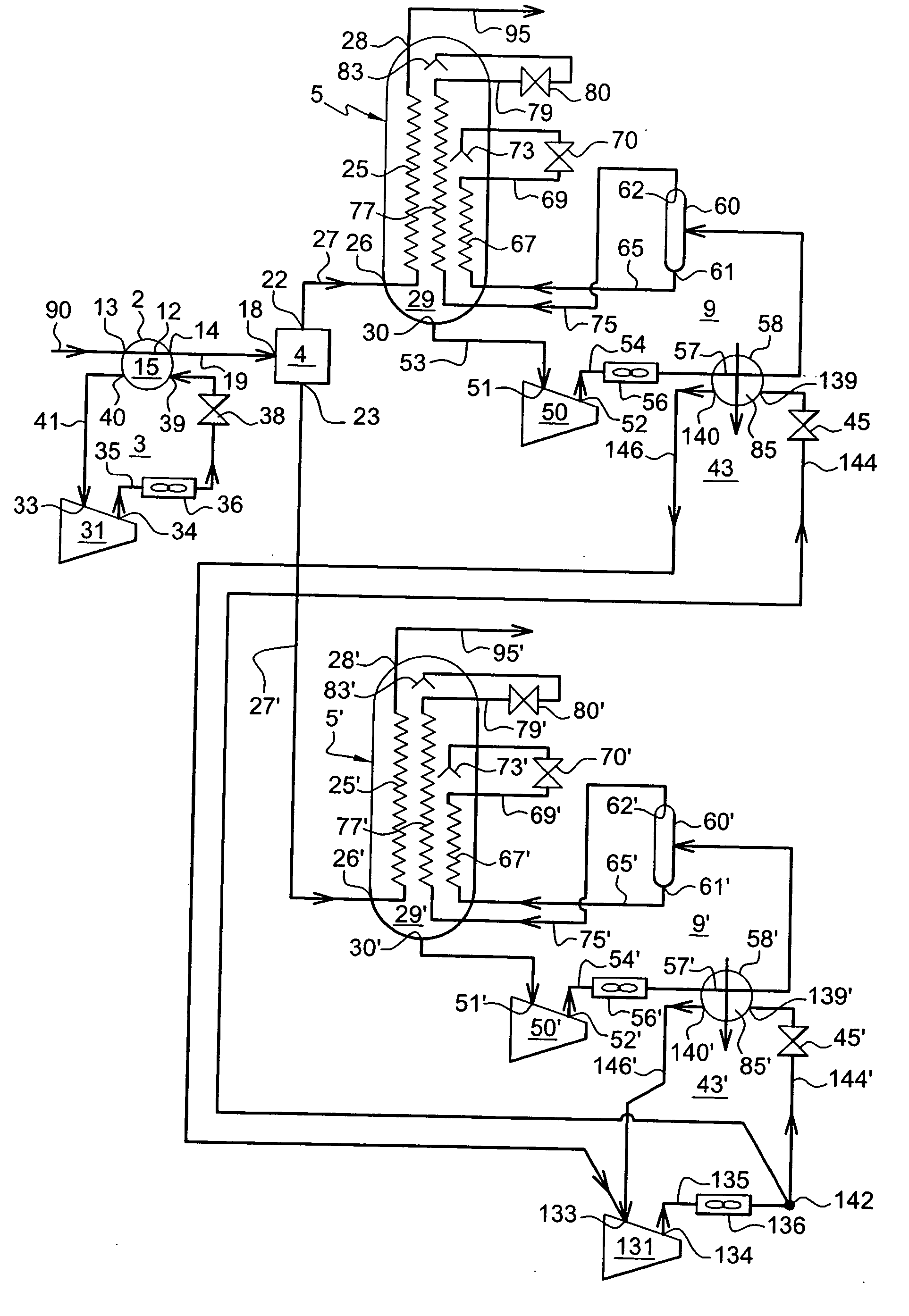

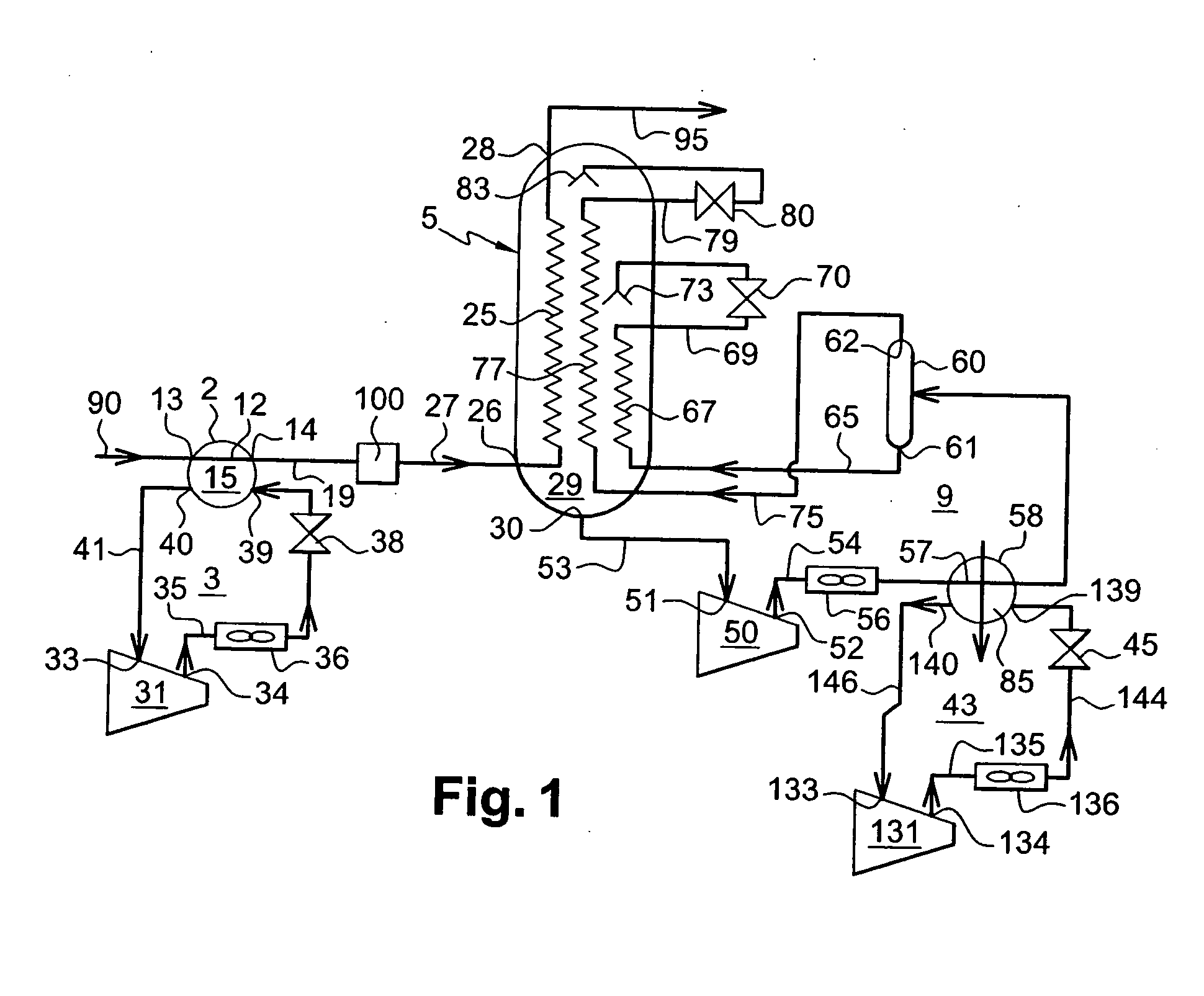

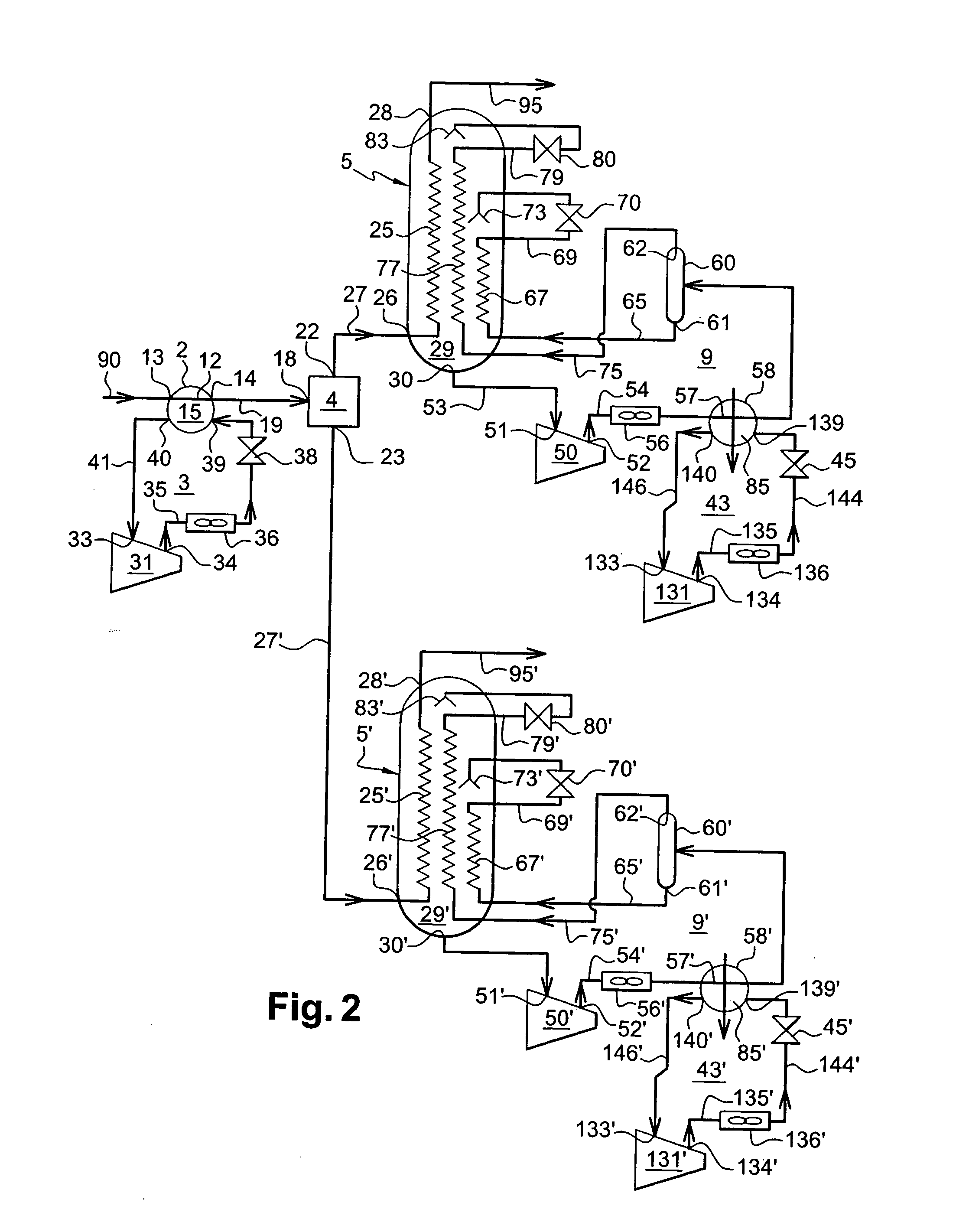

[0060] Reference is made to FIG. 1. The plant for liquefying natural gas according to the present invention comprises one natural gas pre-cooling heat exchanger 2, a pre-cooling refrigerant circuit 3, one main heat exchanger 5, and one main refrigerant circuit 9.

[0061] The natural gas pre-cooling heat exchanger 2 has a hot side in the form of tube 12 that has an inlet 13 for natural gas and an outlet 14 for cooled natural gas. The tube 12 is arranged in the cold side or shell side 15 of the natural gas pre-cooling heat exchanger 2.

[0062] The liquefaction heat exchanger 5 comprises a first hot side 25 having one inlet 26. The inlet 26 of the first hot side 25 is connected to the outlet 14 of the heat exchanger 2, by means of conduit 27. The hot side 25 has an outlet 28 at the top of the liquefaction heat exchanger 5 for liquefied natural gas. The first hot side 25 is located in the cold side 29 of the liquefaction heat exchanger 5, which cold side 29 has an outlet 30.

[0063] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com