Method for preparing zirconium boride/silicon carbide composite powder with low cost

A zirconium diboride and silicon carbide technology, which is applied in the field of low-cost preparation of zirconium diboride/silicon carbide composite powder, can solve the problems of high cost and restrictions on the large-scale application of zirconium diboride/silicon carbide composite materials. Achieve the effects of simple production equipment, simple and easy method, and low cost of zircon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

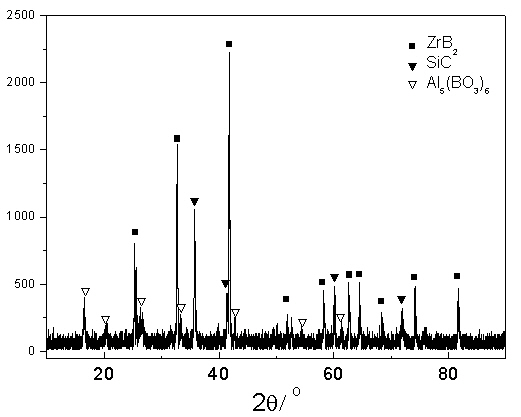

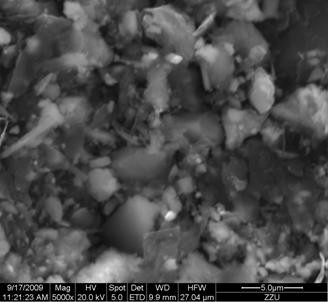

[0020] According to the formula (molar ratio, the same below) is ZrSiO 4 : B 4 C : C = 1 : 0.5 : 4.5 Weigh the ingredients, put the mixture into a ball mill tank, use zirconia balls as the balls, mill for 4 hours, and pass through a 400-mesh sieve. Then, the reaction synthesis was carried out under the protection of argon in a vacuum furnace, and the temperature was kept at 1500° C. for 1 hour. Take out the synthesized powder and put it into a ball mill jar, still using zirconia balls as the balls, and mill for 12 hours. After passing through a 400-mesh sieve, the zirconium diboride / silicon carbide composite powder can be obtained.

Embodiment 2

[0022] The selected formula is: ZrSiO 4 : B 4 C : C = 1 : 0.5 : 5.4, weigh the ingredients, put the mixture into a ball mill jar, use zirconia balls as the balls, mill for 6 hours, and pass through a 300-mesh sieve. Then, the reaction synthesis was carried out in a vacuum furnace under the protection of argon, the synthesis temperature was 1500° C., and the temperature was kept for 1 hour. The synthesized powder was taken out and put into a ball mill jar, and zirconia balls were used as the balls for ball milling for 12 hours. After passing through a 300-mesh sieve, the zirconium diboride / silicon carbide composite powder can be obtained.

Embodiment 3

[0024] According to the formula: ZrSiO 4 : B 4 C : C = 1: 0.5 : 5.85 Weigh the ingredients, put the mixture into a ball mill jar, use zirconia balls as the balls, mill for 6 hours, and pass through a 400-mesh sieve. Then, the reaction synthesis was carried out in a vacuum furnace under the protection of argon, the synthesis temperature was 1500° C., and the temperature was kept for 1 hour. The synthesized powder was taken out and put into a ball mill jar, and zirconia balls were used as the balls for ball milling for 12 hours. Pass through a 400-mesh sieve to obtain zirconium diboride / silicon carbide composite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com