Aluminium oxide and zirconium diboride reinforced aluminum matrix in-situ composite and preparation method thereof

An in-situ composite material, zirconium diboride technology, applied in metal material coating process, coating, etc., can solve the problems of high production cost, unfavorable, coarse particles, etc., achieve high temperature wear resistance and save production cost , the effect of high hardness and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

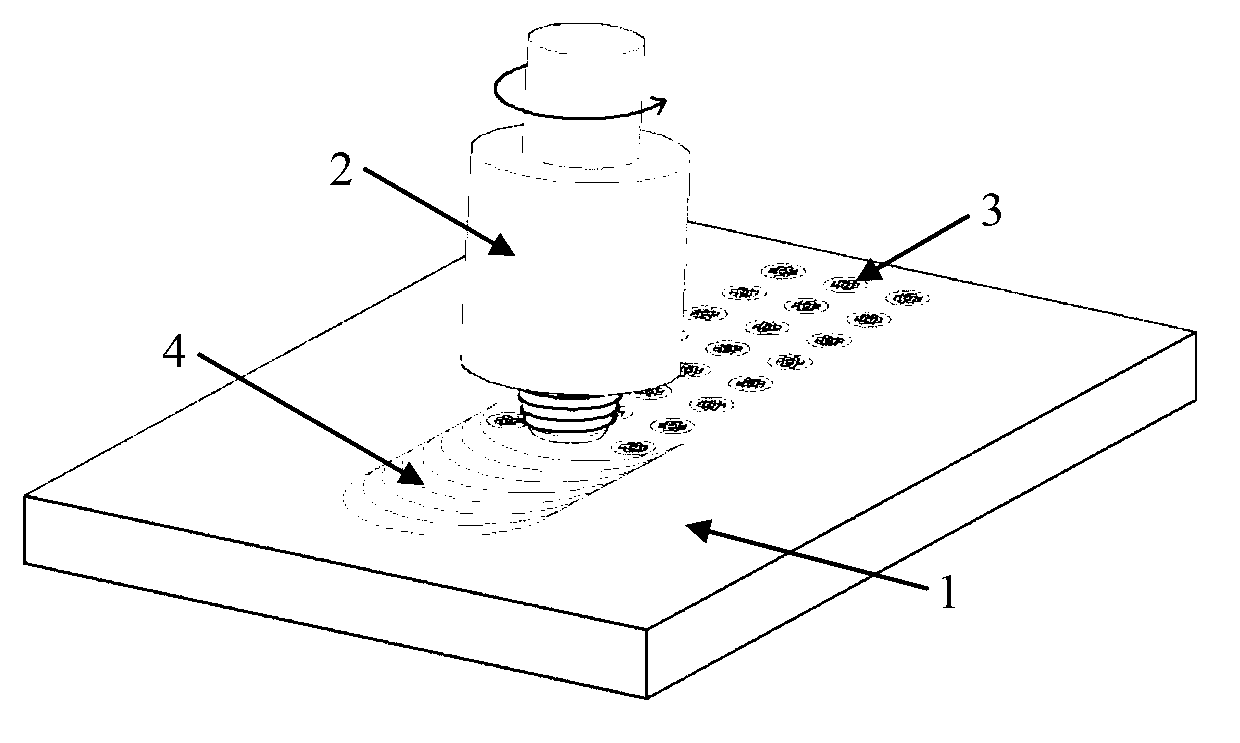

[0025] Base material: 10mm thick 6061 aluminum alloy plate.

[0026] Added particles: monoclinic zirconia (average particle size 80nm, purity 99.8%), amorphous boron (average particle size 500nm, purity 96%).

[0027] ZrO 2 The particles and B particles were mixed at a mass ratio of 11:2, and the mixed particles were ball milled; the ball milling time was 2 hours, the rotation speed was 80r / min, and the ball-to-material ratio was 15:1.

[0028] Three rows of blind holes are processed in the middle area of the aluminum plate, the hole depth and diameter are both 4mm, and the hole spacing is 2mm.

[0029] After ball milling, the mixed particles are poured into the volatile organic solvent, mixed evenly and then added into the blind hole or groove; after the organic solvent volatilizes, fill again until it is filled;

[0030] Friction stir processing in-situ synthesis process parameters: rotation speed 900r / min, travel speed 60mm / min, press amount 0.1mm, inclination angle 2.5...

Embodiment 2

[0033] Base material: 10mm thick 6061 aluminum alloy plate.

[0034] Added particles: monoclinic zirconia (average particle size 80nm, purity 99.8%), amorphous boron (average particle size 500nm, purity 96%).

[0035] ZrO 2The particles and B particles were mixed at a mass ratio of 11:2, and the mixed particles were ball milled; the ball milling time was 3 hours, the rotation speed was 60r / min, and the ball-to-material ratio was 15:1.

[0036] Three rows of blind holes are processed in the middle area of the aluminum plate, the hole depth and diameter are both 4mm, and the hole spacing is 2mm.

[0037] After ball milling, the mixed particles are poured into the volatile organic solvent, mixed evenly and then added into the blind hole or groove; after the organic solvent volatilizes, fill again until it is filled;

[0038] Friction stir processing in-situ synthesis process parameters: rotation speed 1100r / min, travel speed 50mm / min, press amount 0.2mm, inclination angle 2°,...

Embodiment 3

[0041] Base material: 10mm thick aluminum plate.

[0042] Added particles: monoclinic zirconia (average particle size 80nm, purity 99.8%), amorphous boron (average particle size 500nm, purity 96%).

[0043] ZrO 2 The particles and B particles were mixed at a mass ratio of 11:2, and the mixed particles were ball milled; the ball milling time was 8 hours, the rotation speed was 40r / min, and the ball-to-material ratio was 15:1.

[0044] Three rows of blind holes are processed in the middle area of the aluminum plate, the hole depth and diameter are both 4mm, and the hole spacing is 2mm.

[0045] After ball milling, the mixed particles are poured into the volatile organic solvent, mixed evenly and then added into the blind hole or groove; after the organic solvent volatilizes, fill again until it is filled;

[0046] Friction stir processing in-situ synthesis process parameters: rotation speed 600r / min, travel speed 40mm / min, press amount 0.1mm, inclination angle 2.5°, processi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com