Ultrahigh temperature heating furnace

A heating furnace and ultra-high temperature technology, used in lighting and heating equipment, furnaces, muffle furnaces, etc., can solve the problems of polluting the sintered material, unable to meet the needs of scientific research institutes and scientific and technological development, and staying in the laboratory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

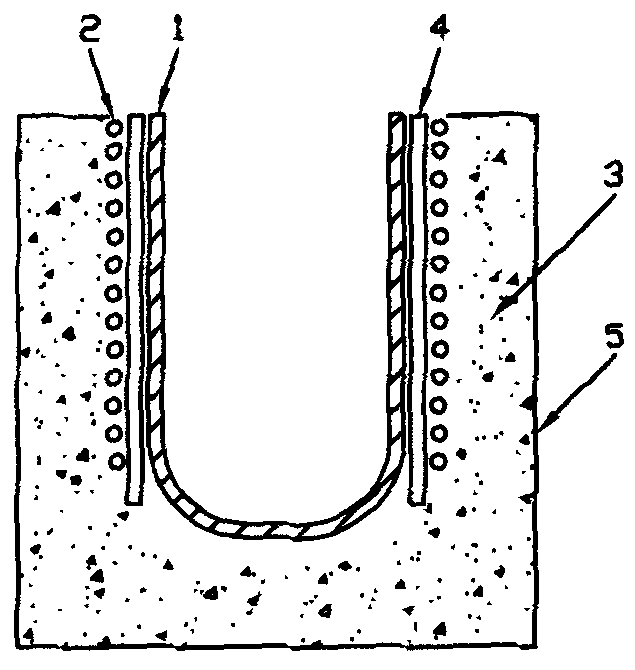

[0022] Embodiment 1: An induction oxidation furnace, also called an induction melting furnace, includes a transformer, a furnace body 5 , a controller, and an insulating material 3 and an insulating material 4 . Induction oxidation furnace of the present invention is first to ZrB 2 The composite ceramic material is made into a zirconium diboride composite ceramic hearth 1, and an induction coil 2 or a copper tube is arranged around a circular hearth to make an inductor. In this embodiment, an induction coil is used. by ZrB 2 The circular hearth made of composite ceramic material is heated by induction, and the sintered object is placed in the hearth for oxidation, with the mouth of the hearth facing up and the bottom of the hearth facing down.

Embodiment 2

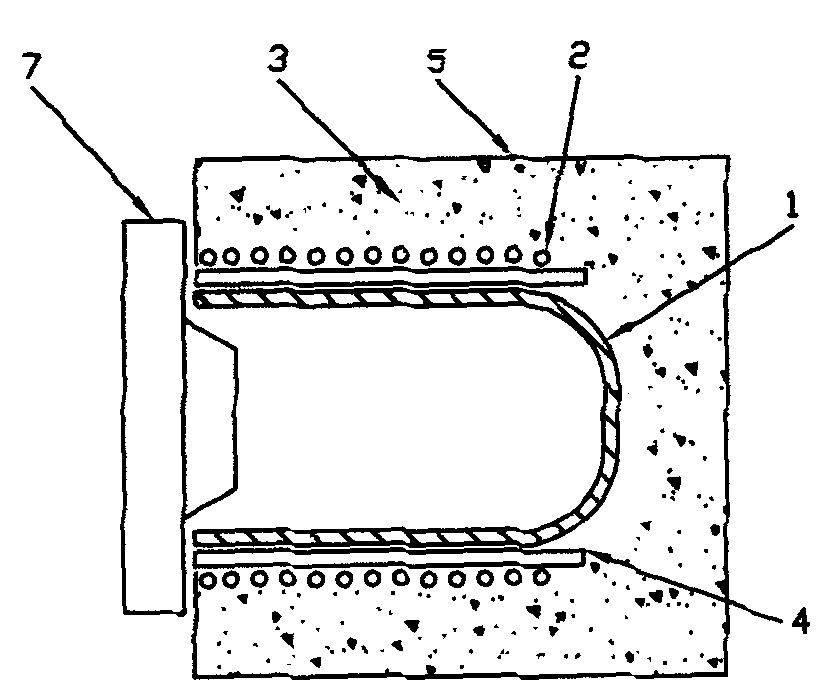

[0023] Embodiment 2: It includes a transformer, a furnace body 5 , a controller, an insulating material 3 and an insulating material 4 . The high-temperature furnace described in this embodiment is first to put ZrB 2 The composite ceramic material is made into a circular or square zirconium diboride composite ceramic hearth 16, which is arc-shaped in this embodiment, and the winding induction coil 2 is made into an inductor, and the ZrB 2 The circular or square furnace made of composite ceramic materials is heated by induction. The sintered object is placed in the furnace for sintering, annealing, etc., the furnace is placed flat, the mouth of the furnace faces forward, and the bottom of the furnace faces backward. A furnace door7.

Embodiment 3

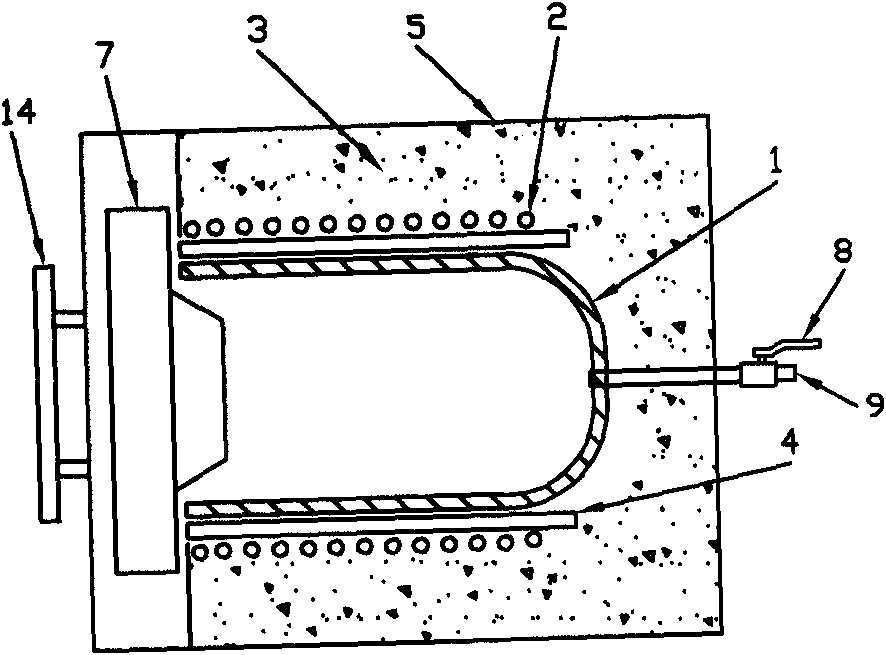

[0024] Embodiment 3: An induction vacuum furnace, also called an induction melting furnace, includes a transformer, a furnace body 5 , a controller, an insulating material 3 , and an insulating material 4 . The induction vacuum furnace of the present embodiment is at first ZrB 2 Composite ceramic materials are used as zirconium diboride composite ceramic hearth 16, and induction coil 2 is arranged around the circular hearth to make an inductor. 2 The circular hearth made of composite ceramic materials is heated by induction. The sintered object is placed in the hearth for sintering, annealing, etc. The hearth is placed flat, the mouth of the hearth faces forward, and the bottom of the hearth faces backward. Door 7, a sealing flange 14 is arranged outside the furnace door 7, such a body of furnace is arranged in a closed metal box, the furnace is connected to a vacuum pump through a pipeline, and a valve 8 and an air extraction port 9 are arranged on the pipeline. Vacuum sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com