High-temperature high-pressure preparation method for titanium diboride

A titanium diboride, high temperature and high pressure technology, which is applied in the field of high temperature and high pressure preparation of titanium diboride, can solve problems such as the difficulty of TiB2 body materials, and achieve the effects of easy implementation, enhanced toughness, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

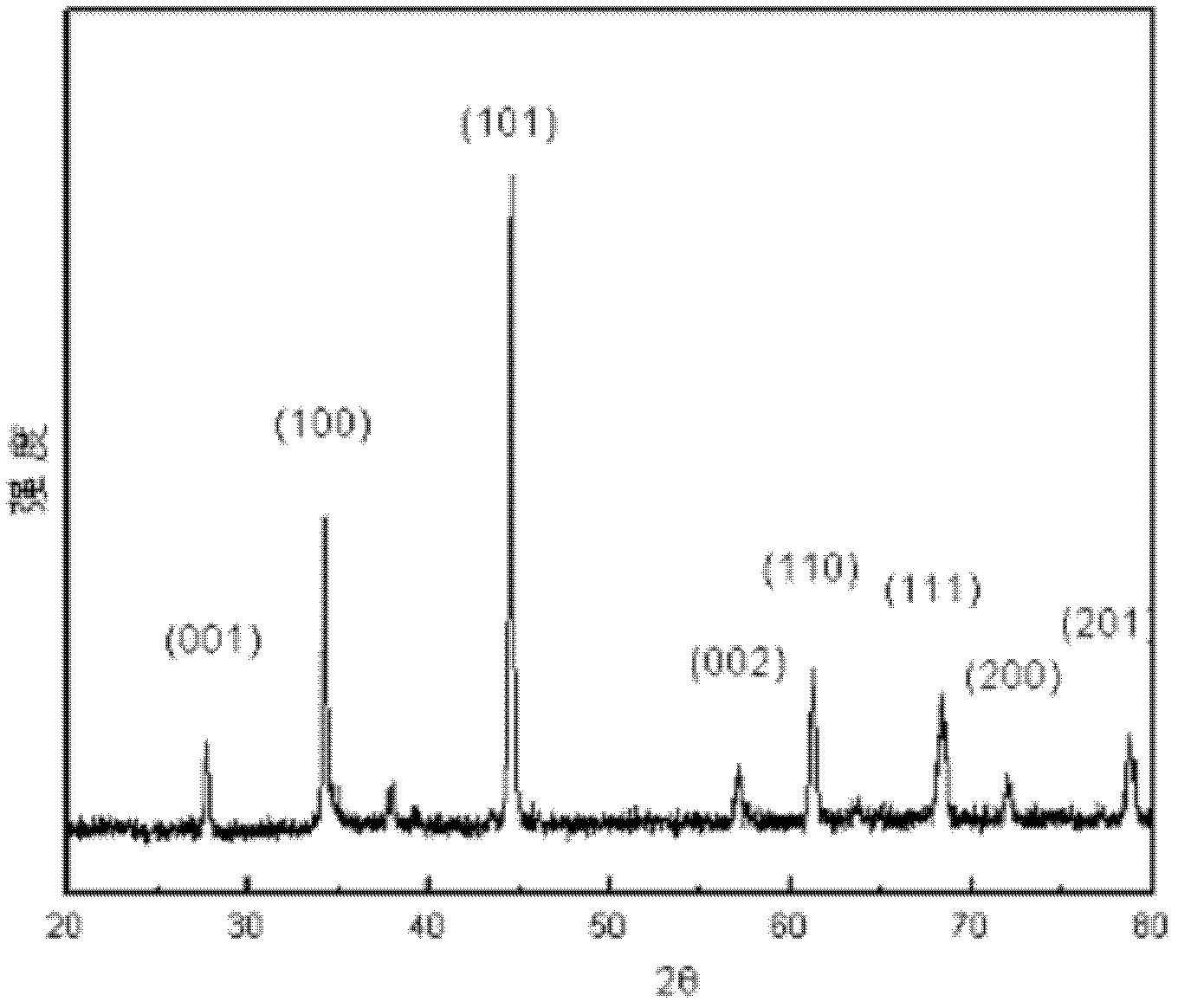

[0022] Mix analytically pure titanium powder (Ti) with a particle size of 1 to 5 microns and boron powder (B) with a particle size of 1 to 5 microns at a molar ratio of 1:8. Graphite is used as the heating tube in the assembly cavity, and pyrophyllite is used as the insulating tube. The synthetic pressure is 4.8GPa, the temperature is 1500K, and the pressure holding time is 1 hour. After the heating is stopped, the sample is naturally cooled to room temperature and the pressure is released. TiB 2 . For specific X-ray results, see figure 1 . When the molar ratio of boron powder and titanium powder is high, the synthesis temperature and holding time of holding pressure can be reduced.

Embodiment 2

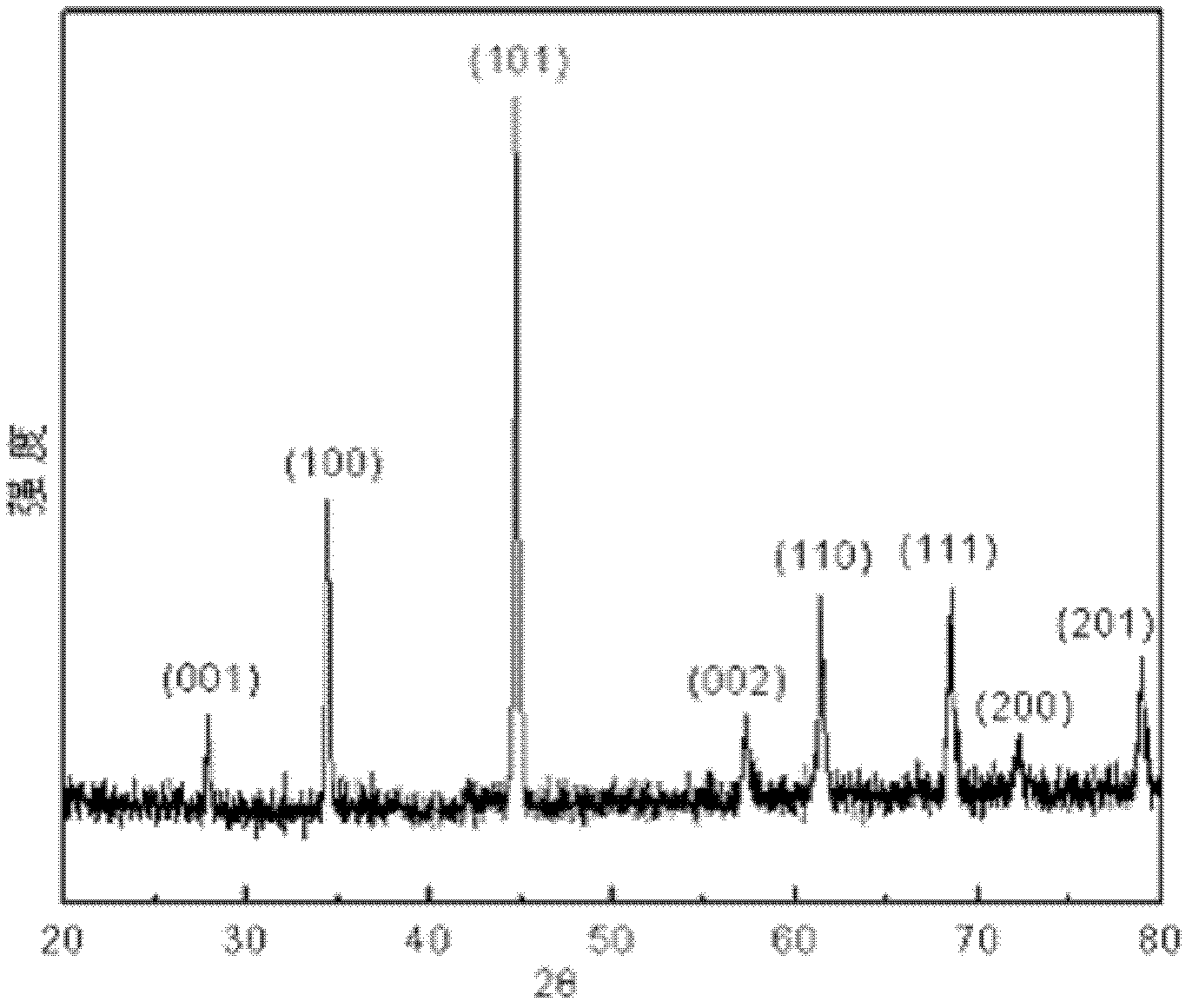

[0024] Adopt the same raw material powder as in Example 1, mix according to molar ratio 1: 2.2, adopt the assembly of Example 1 after powder pressing molding, synthesis pressure is 4.8GPa, temperature 1600K, holding pressure and heat preservation time 2.5 hours, stop heating the sample Naturally cool to room temperature and release pressure, this condition produces pure phase TiB 2 . For specific X-ray results, see figure 2 .

Embodiment 3

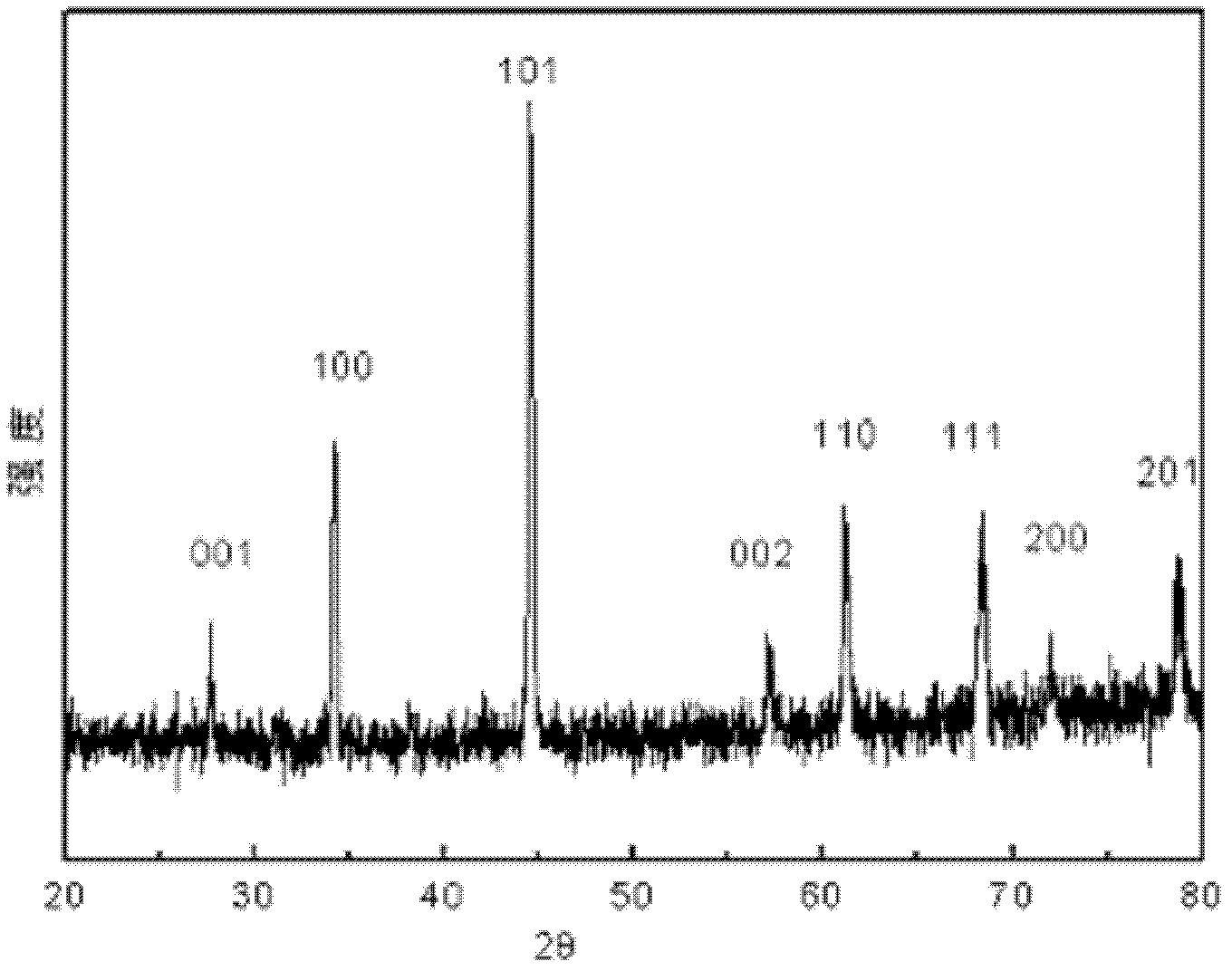

[0026] Adopt the same raw material powder as in Example 1, mix according to the molar ratio of 1:2, adopt the assembly of Example 1 after the powder is pressed, the synthesis pressure is 4.8GPa, the temperature is 1600K, the holding time of pressure and heat preservation is 3 hours, and the sample after stopping heating Naturally cool to room temperature and release pressure, this condition produces pure phase TiB 2 . For specific X-ray results, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com