Method for improving heat shock resistance and strength of ZrB2-SiC superhigh temperature ceramic material

A technology of ultra-high temperature ceramics and thermal shock resistance, which is applied in the field of improving the thermal shock resistance and strength of ceramic materials, can solve the problems of poor strength and poor thermal shock resistance, and achieves improved strength, thermal shock resistance, and thermal resistance. The effect of impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

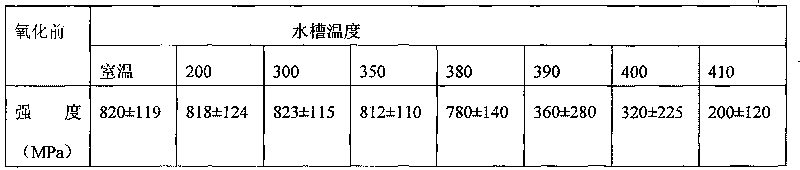

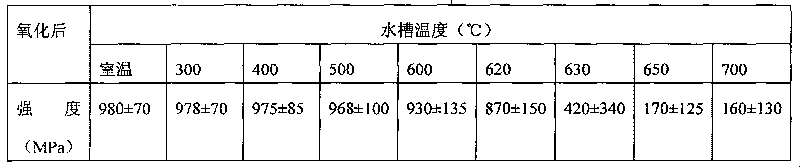

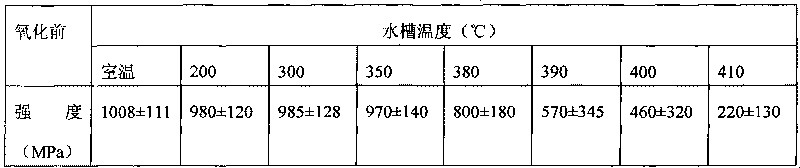

[0007] Specific implementation mode one: this implementation mode improves ZrB 2 -The method for thermal shock resistance and strength of SiC ultra-high temperature ceramic materials is carried out according to the following steps: 1. Take 70-85 parts of zirconium boride powder and 15-30 parts of silicon carbide powder according to the ratio of parts by weight; Put the weighed zirconium boride powder and silicon carbide powder in a star ball mill to mix and disperse, the dispersion medium is absolute ethanol, the speed of the ball mill is 180-200r / min, the mass ratio of the ball mill is 4:1, The amount added is 3 to 5 times the total mass of zirconium boride powder and silicon carbide powder mixed; 3. Dry the mixture obtained in step 2 at 60-65°C to obtain mixed powder; 4. Put the mixed powder in In a graphite mold, sinter in a vacuum or inert atmosphere. The sintering temperature is 1900-2000°C, the sintering pressure is 28-32MPa, the sintering time is 40-60min, and then cool...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the average particle size of the zirconium boride powder in step 1 is 1-5 μm, and the purity of the zirconium boride powder is 98%-99.9%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the average particle size of the silicon carbide powder in step 1 is 30 nm-2 μm, and the purity of the silicon carbide powder is 98%-99.9%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com