Nitride ceramic material microwave sintering method

A nitride ceramic and microwave sintering technology, applied in the field of preparation of inorganic non-metallic nitride ceramic materials, can solve the problems of difficulty in production and application of aluminum nitride ceramic materials, long holding time, low production efficiency, etc. The effect of reaction sintering process, short holding time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

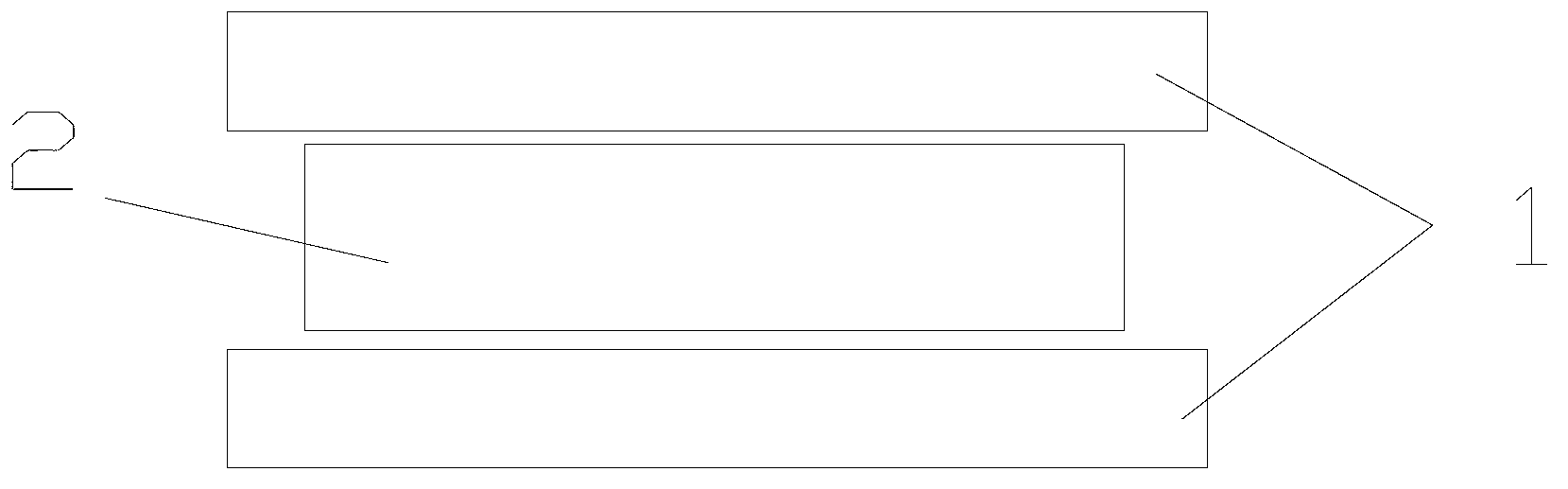

[0014] Combine Japanese Deshan H-grade aluminum nitride powder with 5% high-purity Y 2 o 3 The powder is mixed and pressed into a billet with a size of φ50×10mm, such as figure 1 Shown inside a sagger. The sagger was placed in the sintering chamber of an intermittent industrial microwave oven for microwave sintering, and the microwave frequency was 2.45 GHz. Introduce high-purity nitrogen protection, the pressure is normal pressure, the sintering temperature is 1720 ° C, and the temperature is kept for 2 hours. After cooling, the obtained sintered body is the finished aluminum nitride ceramic material. It has been determined that the thermal conductivity of the prepared aluminum nitride ceramic material is 154W / m·k, and the density is 3.20g / cm 3 , do XRD analysis phase structure is AlN, YAlO 3 .

Embodiment 2

[0016] Mix silicon nitride with a mass percentage of 58% and an appropriate amount of TiC, ZrN, AlN, etc. to make a Ф10mm ball, such as figure 1 Shown inside a sagger. The sagger was placed in the sintering chamber of a continuous industrial microwave oven for microwave sintering, and the microwave frequency was 2.45 GHz. Introduce high-purity nitrogen protection, the pressure is normal pressure, the sintering temperature is 1700 ° C, and the temperature is kept for 2 hours. After cooling, the obtained sintered body is the finished silicon nitride composite ceramic material. After measurement, the density of the finished silicon nitride composite ceramic material is 3.71g / cm 3 , hardness 1520HV.

Embodiment 3

[0018] Combine Japanese Deshan H-grade aluminum nitride powder with 4% high-purity Y 2 o 3 The powder is mixed and pressed into a billet with a size of 50mm×50mm×10mm, such as figure 1 Shown inside a sagger. The sagger was placed in the sintering chamber of an intermittent industrial microwave oven for microwave sintering, and the microwave frequency was 2.45 GHz. The mixed gas protection of nitrogen and hydrogen is introduced, the pressure is normal pressure, the sintering temperature is 1650°C, and the temperature is kept for 10 hours. After cooling, the obtained sintered body is the finished aluminum nitride ceramic material. It has been determined that the thermal conductivity of the prepared aluminum nitride ceramic material is 148W / m·k, and the density is 3.19g / cm 3 , do XRD analysis phase structure is AlN, YAlO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com