Copper particle with surface subjected to antioxidant protection, low-temperature sintered copper paste and sintering process using low-temperature sintered copper paste

A technology of low-temperature sintering and copper particles, which can be used in metal processing equipment, electrical components, circuits, etc., and can solve problems such as low surface energy and insoluble problems that plague the semiconductor packaging industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

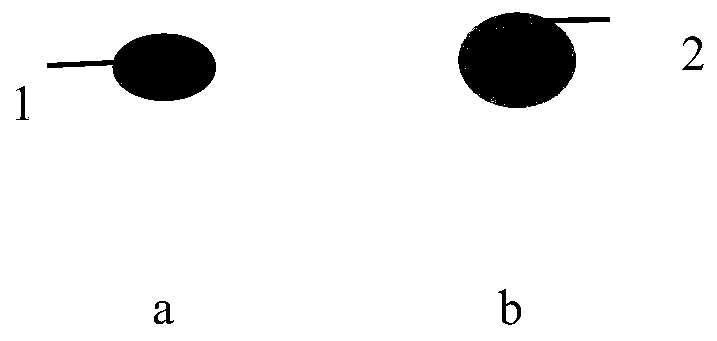

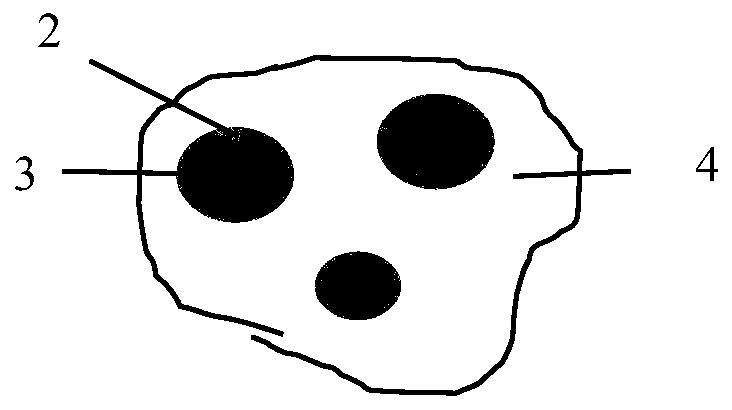

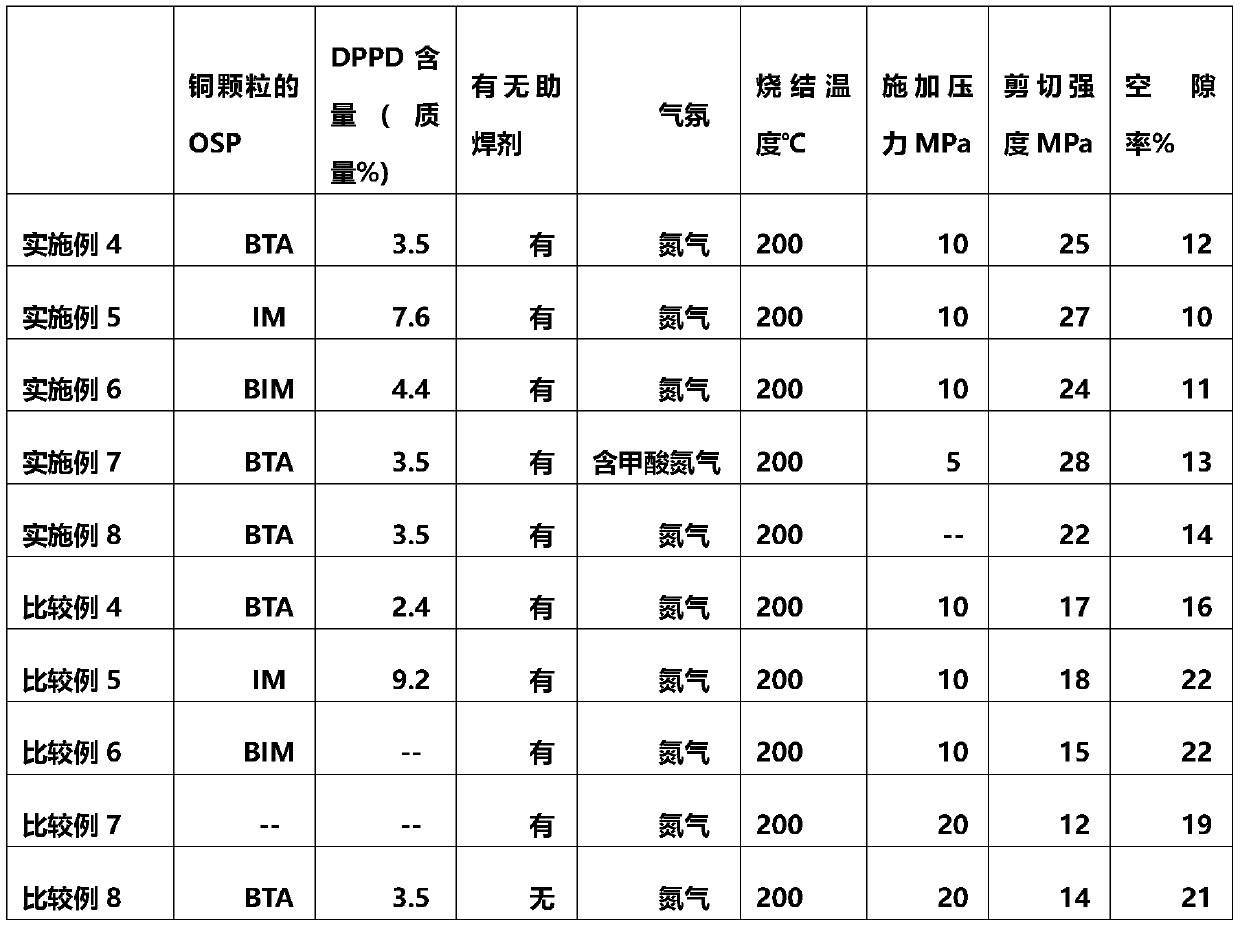

[0043] 10 g of copper particles with an average particle diameter of 0.1 μm were selected, and the configuration of the film-forming solution was: 0.75 g of BTA; 0.03 g of DPPD; and 500 ml of water. After film formation, it was confirmed by TEM that a uniform OSP film was formed on the surface of the copper particles with a film thickness of about 5 nm, and it was confirmed by XPS that the DPPD content in the OSP film was about 3.5% by mass.

Embodiment 2

[0045] 12 g of copper particles with an average particle diameter of 1 μm were selected, and the configuration of the film-forming solution was: 1.25 g of IM; 0.12 g of DPPD; and 500 ml of water. After film formation, it was confirmed by TEM that a uniform OSP film was formed on the surface of the copper particles with a film thickness of about 60 nm, and it was confirmed by XPS that the DPPD content in the OSP film was about 7.6% by mass.

Embodiment 3

[0047] 10 g of copper particles with an average particle diameter of 8 μm were selected, and the configuration of the film-forming solution was: 1 g of BIM; 0.05 g of DPPD; and 500 ml of water. After film formation, it was confirmed by TEM that a uniform OSP film was formed on the surface of the copper particles with a film thickness of about 50 nm, and it was confirmed by XPS that the DPPD content in the OSP film was about 4.4% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com