Method for preparing eutectic composite LaB6-VB2 through spark plasma sintering technology

A discharge plasma, lab6-vb2 technology is applied in the field of preparation of LaB6-VB2 eutectic composite materials, and achieves the effects of uniform heating, simple method and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

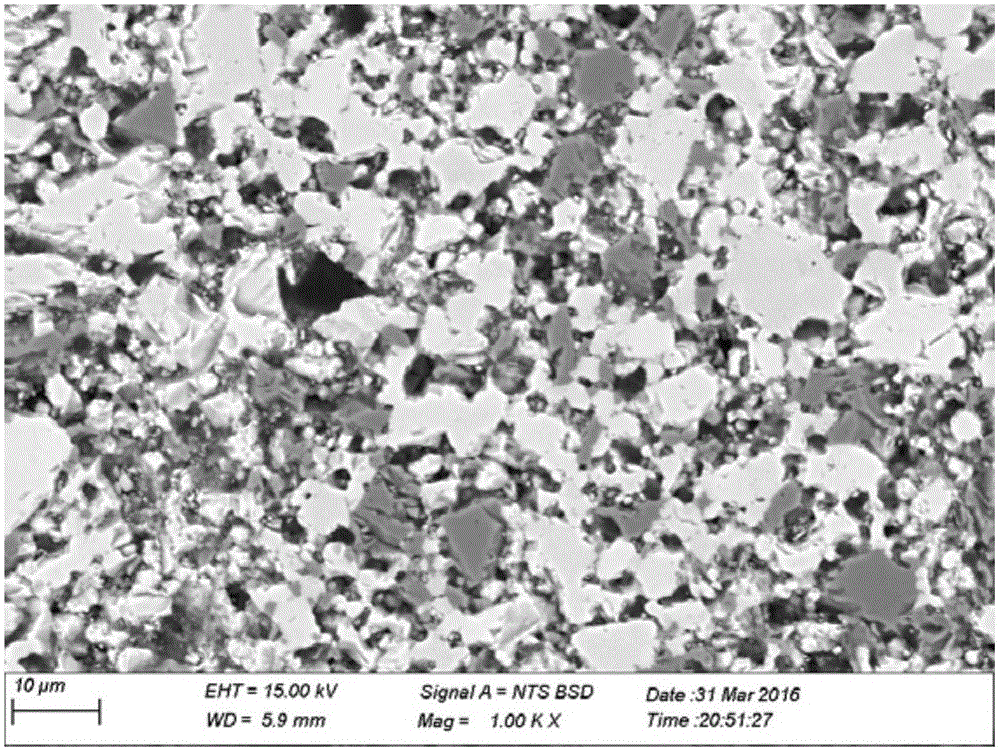

Embodiment 1

[0025] In this example, LaB was prepared according to the following steps 6 -VB 2 Eutectic composites:

[0026] Step 1. Mixing

[0027] LaB with a particle size of 45 μm 6 Powder and VB with particle size of 3-5mm 2 Powder is the raw material. LaB 6 Powder and VB 2 The powders are respectively ball milled and refined to make the particle size basically the same, LaB 6 and VB 2 The time for the refinement of the raw material powder is 2h and 3h, respectively.

[0028] LaB according to the mass percentage of the eutectic phase diagram 6 Powder and VB 2 The powders were mixed in a glove box and then uniformly processed on a planetary ball mill for 2 h to obtain LaB 6 -VB 2 Mix powder; mix LaB 6 / VB 2 The mixed powder was placed in a vacuum drying box and dried at 100°C for 10h;

[0029] Step 2. Powder pre-pressing

[0030] LaB after drying 6 -VB 2 The mixed powder is loaded into a graphite mold, and then the graphite mold is placed on a manual press for pre-comp...

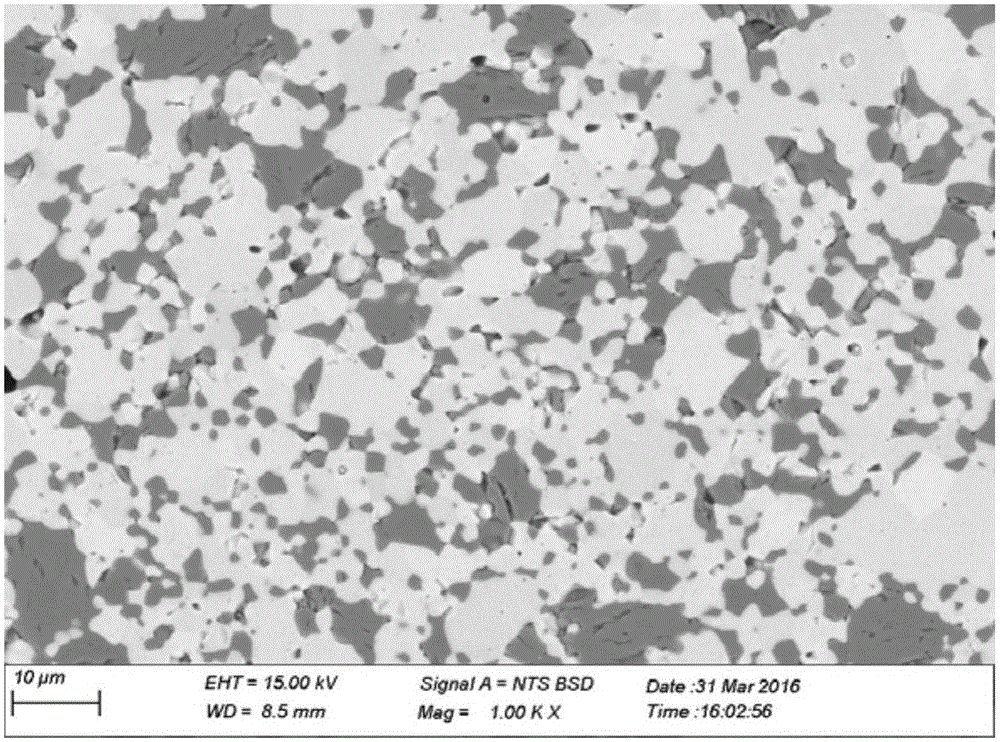

Embodiment 2

[0035] In this example, LaB was prepared according to the following steps 6 -VB 2 Eutectic composites:

[0036] Step 1. Mixing

[0037] LaB with a particle size of 45 μm 6 Powder and VB with particle size of 3-5mm 2 Powder is the raw material. LaB 6 Powder and VB 2 The powders are respectively ball milled and refined to make the particle size basically the same, LaB 6 and VB 2 The time for the refinement of the raw material powder is 2h and 3h, respectively.

[0038] LaB according to the mass percentage of the eutectic phase diagram 6 Powder and VB 2 The powders were mixed in a glove box and then uniformly processed on a planetary ball mill for 2 h to obtain LaB 6 -VB 2 Mix powder; mix LaB 6 / VB 2 The mixed powder was placed in a vacuum drying box and dried at 100°C for 10h;

[0039] Step 2. Powder pre-pressing

[0040] LaB after drying 6 -VB 2 The mixed powder is loaded into a graphite mold, and then the graphite mold is placed on a manual press for pre-comp...

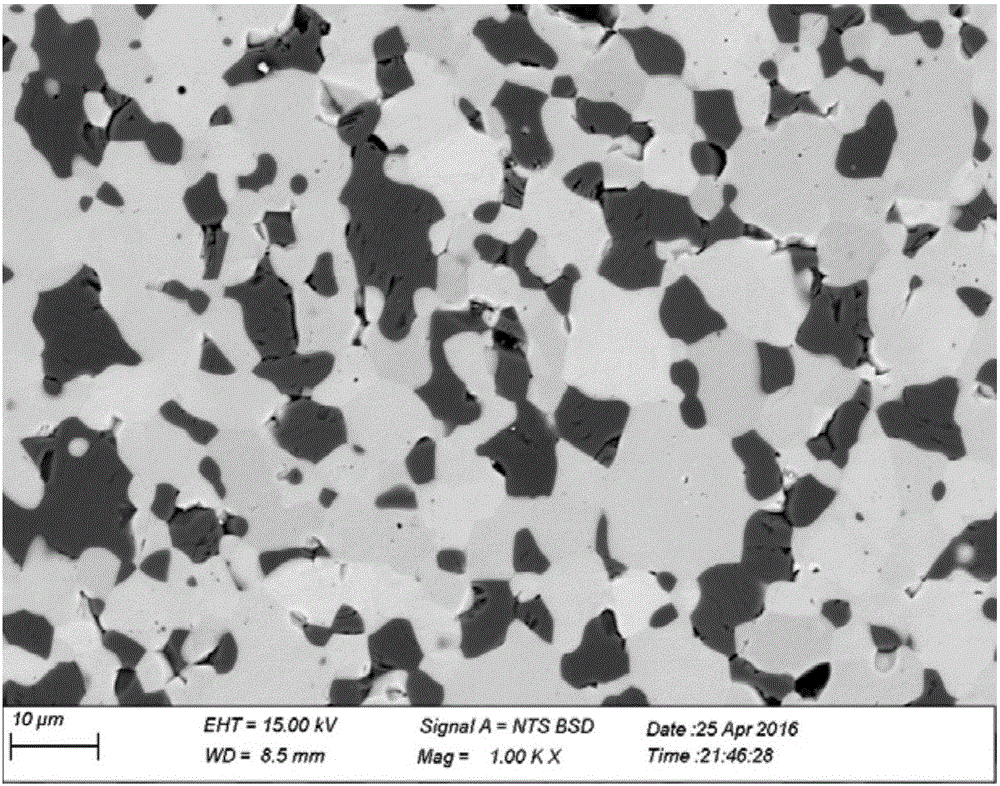

Embodiment 3

[0045] In this example, LaB was prepared according to the following steps 6 -VB 2 Eutectic composites:

[0046] Step 1. Mixing

[0047] LaB with a particle size of 45 μm 6 Powder and VB with particle size of 3-5mm 2 Powder is the raw material. LaB 6 Powder and VB 2 The powders are respectively ball milled and refined to make the particle size basically the same, LaB 6 and VB 2 The time for the refinement of the raw material powder is 2h and 3h, respectively.

[0048] LaB according to the mass percentage of the eutectic phase diagram 6 Powder and VB 2 The powders were mixed in a glove box and then uniformly processed on a planetary ball mill for 2 h to obtain LaB 6 -VB 2 Mix powder; mix LaB 6 / VB 2 The mixed powder was placed in a vacuum drying box and dried at 100°C for 10h;

[0049] Step 2. Powder pre-pressing

[0050] LaB after drying 6 -VB 2 The mixed powder is loaded into a graphite mold, and then the graphite mold is placed on a manual press for pre-comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com