Ceramic dielectric material matched with nickel inner electrode and production method of capacitor produced by ceramic dielectric material

A technology of ceramic dielectric and inner electrode, applied in capacitors, fixed capacitors, multilayer capacitors, etc., can solve the problem of high cost and achieve the effect of good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

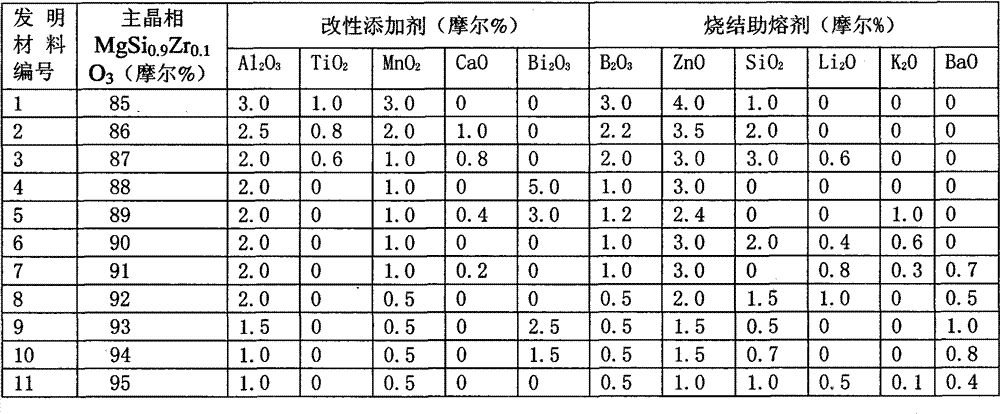

[0017] An anti-reduction nickel electrode high frequency low dielectric ceramic dielectric material, the raw material with a purity of more than 99.5% is selected, and 1.0 mole of Mg(OH) 2 , 0.9 mol SiO 2 , 0.1 mol ZrO 2 The mixing ratio is uniform, and the mixture is calcined at 1170°C for 3 hours, and the main crystal phase is MgSi 0.9 Zr 0.1 o 3 s material. Then add the modifying additives and sintering aids shown in Table 1 in predetermined proportions.

[0018] Table 1: Formulation composition of main crystal phase, modifying additives, and sintering flux

[0019]

[0020] According to the production process of ceramic materials commonly used by those skilled in the art, MLCC ceramic materials are produced. In the production process of chip MLCC, organic binders and solvents such as ethanol are first added to form a slurry, and the slurry is cast into a film. sheet, print nickel Ni internal electrodes on the diaphragm, alternately laminate the required number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com