Multilayer clip ceramic capacitor dielectric material and capacitor thereof

A multi-layer chip ceramic and capacitor dielectric technology, which is applied in the direction of fixed capacitor dielectric, laminated capacitor, fixed capacitor parts, etc., can solve the problem of high cost of silver-palladium inner electrode, and achieve good high-frequency high-Q electrical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

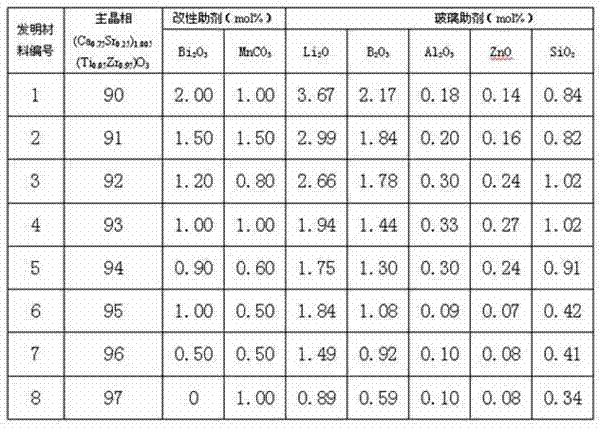

[0022] A high-frequency dielectric ceramic material matched with copper electrodes, the raw materials with a purity of more than 99.5% are selected, with (Ca 0.75 Sr 0.25 ) 1.005 (Ti 0.05 Zr 0.95 )O 3 Proportioning method, choose 1.0 mole of CaCO 3 , 0.25 moles of SrCO 3 , 0.0663 moles of TiO 2 , 1.2603 moles of ZrO 2 The mixing ratio is uniformly dispersed and mixed by sand milling, and calcined at 1250°C for 2.5 hours to obtain (Ca 0.75 Sr 0.25 ) 1.005 (Ti 0.05 Zr 0.95 )O 3 main crystalline material.

[0023] Described glass additive is Li 2 O.B 2 o 3 、Al 2 o 3 , ZnO, SiO2 After measuring the weight of the powder in mol%, the required particle size was obtained by sand milling. especially B 2 o 3 Since it is in the form of glass with a size of 2mm, it is difficult to crush. Then after drying and mixing, put it into a platinum crucible and keep the temperature at 1200-1350°C for 2 hours, then put the melted liquid into cold water for rapid cooling. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com