Soaking fault-prevention selective laser sintering device and manufacturing method thereof

A technology of laser sintering and laser scanning devices, which is applied in the field of selective laser sintering devices for uniform heating and anti-faulting, can solve problems such as uneven distance from heating points, poor preheating uniformity of powder materials, and delamination fractures, etc., and achieves improvement Performance and stability, stable structure of sintered products, uniform performance of sintered products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

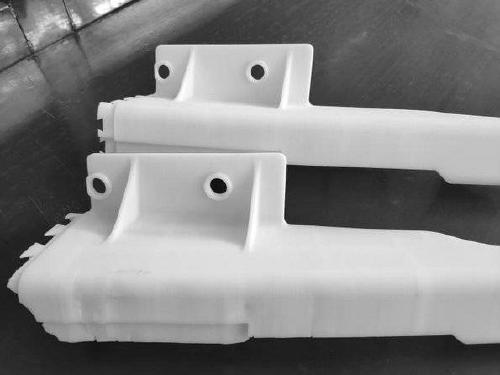

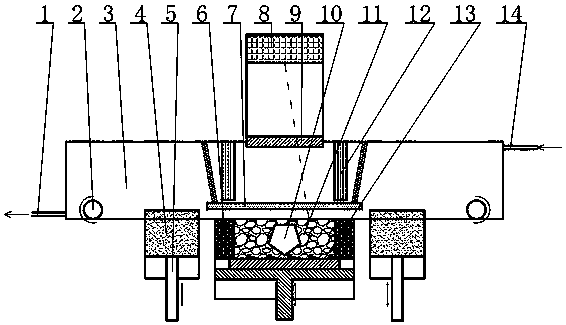

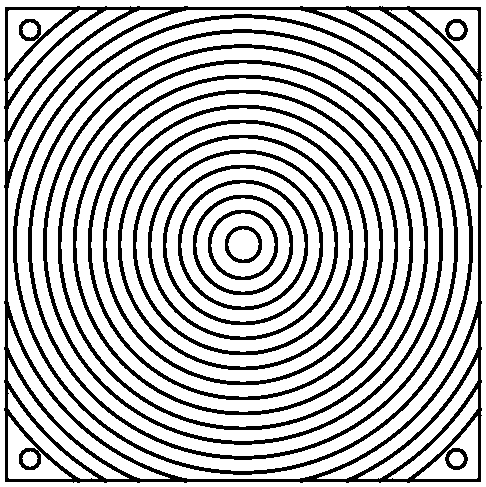

[0023] a kind of like figure 1 The selective laser sintering device for soaking heat and preventing faults is composed of a machine base, a laser scanning device 8, a printing working chamber 3, a feeding device, and a molding chamber 11, wherein the laser scanning device 8 passes through the laser channel and the laser scanning device arranged at the lower end of the laser channel The protective light-transmitting plate 9 communicates with the printing working chamber 3, so that the laser can transmit to the upper surface of the molding chamber 11 located below the center of the bottom of the printing working chamber 3; the laser sintering device controls the laser emission angle and position by adjusting the laser scanning device 8 The base powder cooperates with the movement of the piston assembly 13 in the molding chamber to print the parts 10 layer by layer; the upper right side of the printing working chamber 3 is provided with a protective gas inlet 14, the lower left si...

Embodiment 2

[0031] The whole is consistent with Example 1, the difference is:

[0032] The soaking block 6 is made of aluminum nitride ceramics

[0033] Compared with Example 1, the curing ability of the soaking block remains unchanged, but the soaking ability becomes worse. With pure PA12 as the base material, the average elongation of the product printed in this example is 1.6% lower than that of the printed product in Example 1. .

Embodiment 3

[0035] The whole is consistent with Example 1, the difference is:

[0036] The soaking block 6 is made of tempered glass

[0037] Compared with Example 1, the solidification ability of the soaking block is enhanced, but the soaking ability is worsened. With pure PA12 as the basic material, the dimensional accuracy of the product printed in this example is increased by 0.1% (such as the design size of 10mm, the implementation Example 1 prints out 10.03mm, this embodiment is 10.02, of course, this data is only for rough analogy, can not compare all sizes accurately, but the overall trend still has statistical significance), the average elongation rate is lower than the implementation Example 1 print product 2.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| etching depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com