plutonium dioxide raw material pretreatment device for mox

A pretreatment device, plutonium dioxide technology, applied in the field of pretreatment, can solve the problems of not meeting the pretreatment requirements of radioactive materials, atmosphere and temperature control, exhaust gas treatment and insufficient consideration of radiation protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

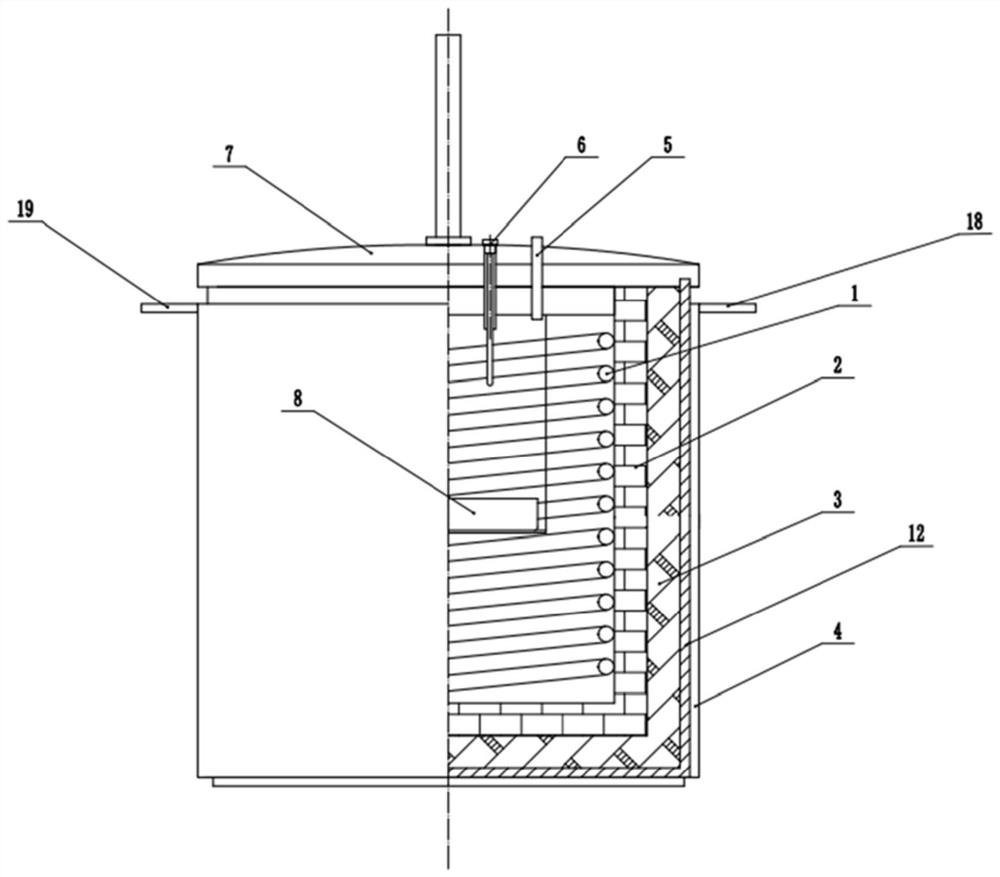

[0023] A plutonium dioxide pretreatment device for MOX, such as image 3 As shown, the resistance furnace body consists of electric heating element 1, refractory material 2, heat preservation material 3, furnace shell 12, and cooling water jacket 4 from the inside to the outside; the furnace shell 12 is made of a 5mm thick ordinary steel plate as a fixing and furnace support structure The electric heating element 1 adopts a nickel-chromium electric heating element, the material model is Cr20Ni80, which is a spiral mechanism, and is fixed around the furnace cavity of the resistance furnace through the bricks fixed on the refractory material 2, and the electrode of the electric heating element 1 is placed on the furnace body. The electrodes are connected by quick plug-in, and the electric heating element can be quickly lifted and placed by the sling for easy replacement.

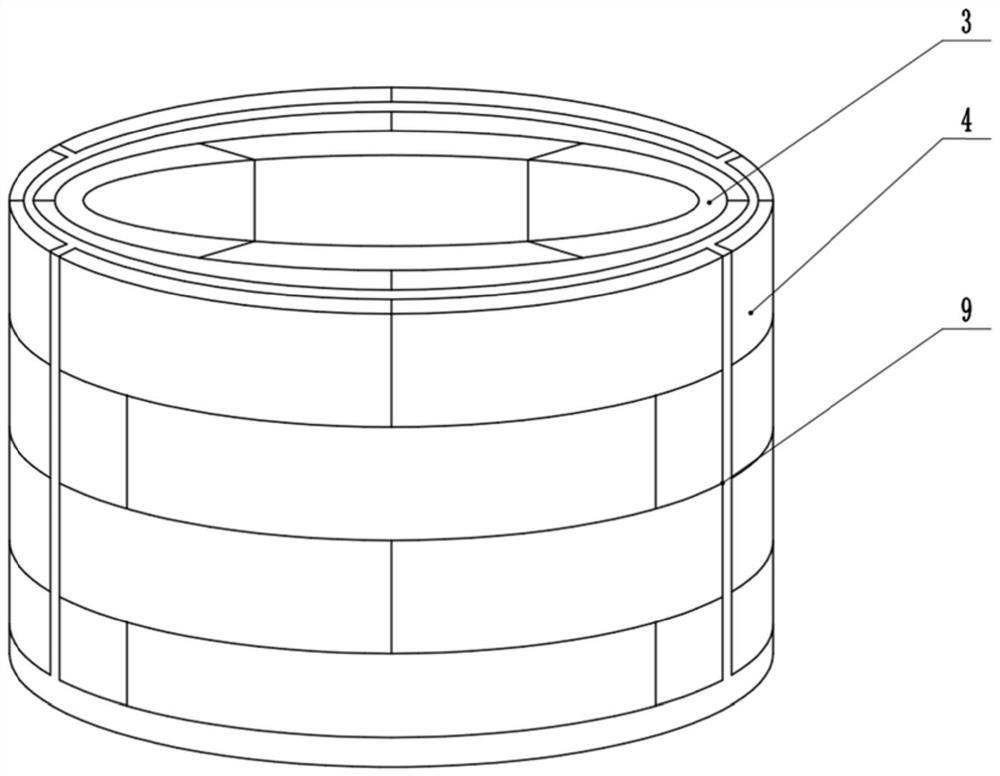

[0024] Such as figure 1 As shown, the refractory material 2 is clay bricks, and the thermal insulation mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com