A sintering method using cdq powder for sintering

A sintering method and technology for mixing powder, applied in the field of sintering using CDQ powder, can solve the problems of fluctuation in the sintering process, easy to be drawn into the large flue, and the strength of the sintered ore is reduced, so as to stabilize the sintering process and improve the granulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

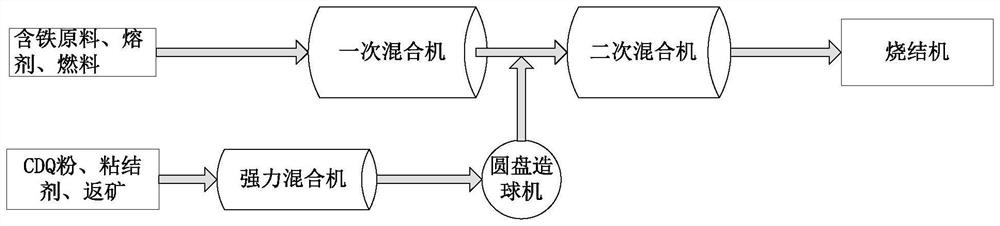

Method used

Image

Examples

Embodiment 1

[0032] In Example 1, the central value of basicity of sintered ore was determined to be 1.90 times, and CD Q powder pellets were spread on the belt after the first mixer, and the output was controlled to 6t per hour.

[0033] Specifically, by weight percentage, the mixture is composed as follows: 59.8% of mixed powder, 25% of returned ore, 3.7% of coal powder, 4% of limestone, 4.5% of dolomite, and 3.0% of granular ash.

[0034] Specifically, in terms of percentage by weight, the mixed powder is composed as follows: 23% card powder, 10% A powder, 46% Yangdi powder, 4% Sic concentrate, 5% ultra-special powder, 4% Leike powder, Iron dust mud 2%, New Zealand powder 4%, plum essence 2%.

[0035] By adopting the above technical solutions, the mixed iron powder with the required chemical composition is obtained, the planned TFe value is 60.37%, the SiO 2 Planned value 4.84%, trace element control: Al 2 O 3 The planned value is 1.53%, the planned value of Mn is 0.106%, the planned...

Embodiment 2

[0038] In Example 2, the central value of basicity of sintered ore was determined to be 1.85 times, and CD Q powder pellets were spread on the belt after the primary mixer, and the output was controlled to 8t per hour.

[0039] By weight percentage, the composition of the mixture is as follows: mixed powder (60)%, returned ore (25)%, coal powder (3.8)%, limestone (4)%, dolomite (4.2)%, granular ash ( 3.0)%.

[0040] By weight percentage, the composition of the mixed powder is as follows: card powder (23)%, A powder (10)%, Yangdi powder (46)%, Sic concentrate (4)%, ultra-special powder (5)% , Lake powder (4)%, iron dust mud (2)%, new powder (4)%, plum essence (2)%.

[0041] By adopting the above technical solutions, the mixed iron powder with the required chemical composition is obtained, the planned TFe value is 60.37%, the SiO 2 Planned value 4.84%, trace element control: Al 2 O 3 The planned value is 1.53%, the planned value of Mn is 0.106%, the planned value of S is 0.016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com