BaTiO3-based fine-grain ceramic with giant dielectric constant, low loss and high resistivity and preparation method of BaTiO3-based fine-grain ceramic

A technology of giant dielectric constant and high resistivity, applied in the field of BaTiO3-based fine-grained ceramics and its preparation, to achieve the effects of wide source, low price and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a kind of BaTiO with huge dielectric constant, low loss and high resistivity 3 The preparation method of base fine-grained ceramics comprises the following steps:

[0050] a) BaTiO 3 with MAS, Ln 2 o 3 , MnO 2 , MgO is mixed with water and ball-milled and then dried to obtain a mixed powder;

[0051] b) Mix the mixed powder obtained in step a) with a binder, and then successively undergo granulation, sieving, molding, debinding and sintering to obtain BaTiO with a large dielectric constant, low loss and high resistivity 3 based fine-grained ceramic materials.

[0052] In the present invention, BaTiO 3 with MAS, Ln 2 o 3 , MnO 2 , MgO and water are mixed and ball-milled and then dried to obtain a mixed powder. In the present invention, the BaTiO 3 with MAS, Ln 2 o 3 , MnO 2 , MgO adopts analytically pure powder raw materials well known to those skilled in the art, and all of them can be obtained from commercially availabl...

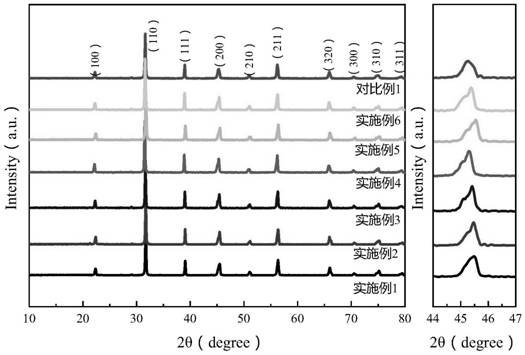

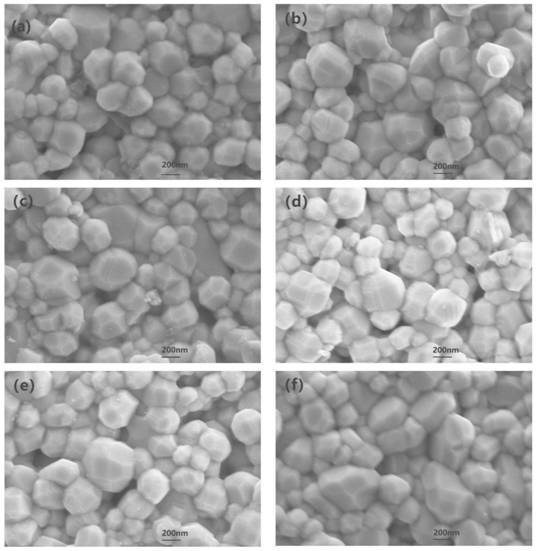

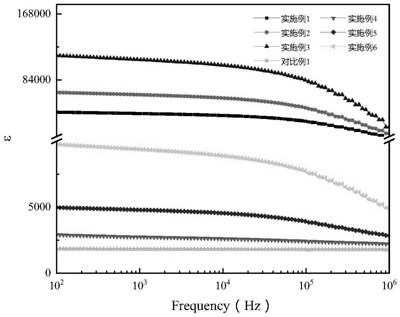

Embodiment 1

[0071] A temperature-stable BaTiO with giant permittivity, low loss, and high resistivity 3 Base fine-grain ceramic material and preparation method thereof, the concrete steps of this preparation method are:

[0072] (1) BaTiO 3 Powder with 2wt% MAS, 0.4mol% Y 2 o 3 , 0.6mol% MnO 2 , 0.5mol% MgO powder, mixed with deionized water and ball milled for 12 hours, then dried to obtain the corresponding mixed ceramic powder.

[0073] (2) The ceramic powder that step (1) obtains is added the PVA binder of mass ratio 5%, granulates, sieves, molding, makes the ceramic green body of diameter~10mm, thickness~1mm; Ceramic green body is in h 2 : N 2 =0.5%: sintering in an atmosphere of 99.5% (volume ratio), during the sintering process, it must be kept at 600°C (heating rate 3°C / min) for 2 hours to remove the glue, and then heated to 1150°C for sintering, and kept for 3 hours to obtain BaTiO with giant dielectric constant, low loss and high resistivity and temperature stability 3 b...

Embodiment 2

[0078] A temperature-stable BaTiO with giant permittivity, low loss and high resistivity 3 Base fine-grained ceramic material, the specific steps of its preparation method are:

[0079] (1) BaTiO 3 Powder with 2wt% MAS, 0.4mol% Y 2 o 3 , 0.6mol% MnO 2 , 0.5mol% MgO powder, mixed with deionized water and ball milled for 12 hours, then dried to obtain ceramic powder.

[0080] (2) the ceramic powder that step (1) obtains is added the PVA binding agent of mass ratio 5%, granulates, sieves, molding, makes the ceramic green body of diameter~10mm, thickness~1mm; Ceramic green body is in H 2 : N 2 =0.5%: Sintering in an atmosphere of 99.5% (volume ratio). During the sintering process, it must be kept at 600°C (heating rate 3°C / min) for 2 hours to debinding, and then heated to 1170°C for sintering and kept for 3 hours to obtain a giant Dielectric constant, low loss and high resistivity with temperature stable BaTiO 3 based fine-grained ceramics.

[0081] The BaTiO with giant di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com