Ore blending method for blending ferrodolomite into low-magnetism crude iron ore

An iron dolomite and weak magnetic technology, applied in the fields of mining and mineral engineering, can solve the problems of shortened mine service life, reduced recovery rate of black ditch, low resource utilization rate, etc., so as to improve resource utilization efficiency and reduce waste rock discharge. , the effect of reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

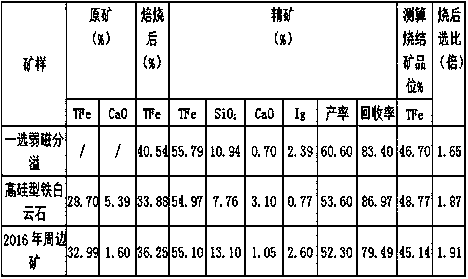

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific embodiments.

[0036] A method for blending iron dolomite into weakly magnetic iron ore, specifically comprising the following steps:

[0037] (1) The data acquisition of iron ore resources planned to be mined is determined through the existing production and exploration data and the distribution area and grade of iron ore and iron dolomite at each level in the stope planned to be mined; Distribution situation, conduct laboratory analysis on samples from blasting drill holes, and delineate the detailed location, quantity, iron grade and CaO content of iron dolomite;

[0038] (2) Formulate iron grade and calcium oxide content targets for iron ore output;

[0039] (3) Establish the ore blending model of iron ore and iron dolomite;

[0040] (4) Export the quantity of iron dolomite ore blending;

[0041] The described ore distribution model is:

[0042] objective function (1)

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com