Method and device for strengthening inner wall of middle-small diameter long tube through laser shot blasting

A technology of laser peening, medium and small diameter, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of poor surface quality, uneven shot peening, and blocked feed movement, etc., to achieve good strengthening effect, uniform effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

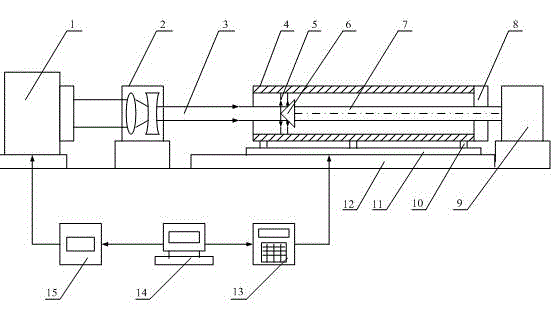

[0033] Such as Figure 1-3 shown.

[0034] A method for strengthening the inner wall of a medium-small diameter long tube by laser shot peening, the specific steps of which are:

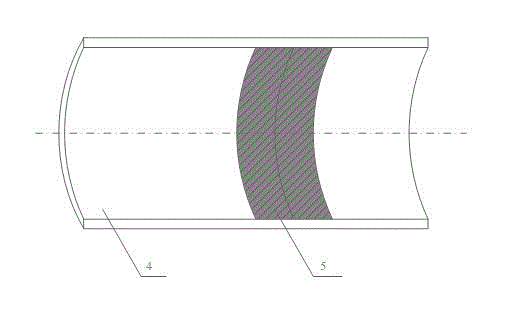

[0035]1) Select a copper pipe according to the inner diameter and length of the pipe fitting 4 to be strengthened, first coat a thin layer of transparent engine oil (10 μm) on the outer surface of the copper pipe, and then wrap a layer of flexible film for laser strengthening, so that the wrapped The diameter of the copper pipe with the film is slightly smaller than the diameter of the inner wall of the pipe fitting. Insert the copper pipe wrapped with the film into the inner wall of the pipe fitting 4, heat the copper pipe, and expand the flexible film to stick to the inner wall of the pipe fitting 4. After cooling, the copper pipe is separated from the film and pulled out. Copper pipe, this kind of flexible film can adopt the flexible film disclosed by the patent invention with publication number ...

Embodiment 2

[0044] Such as figure 1 shown.

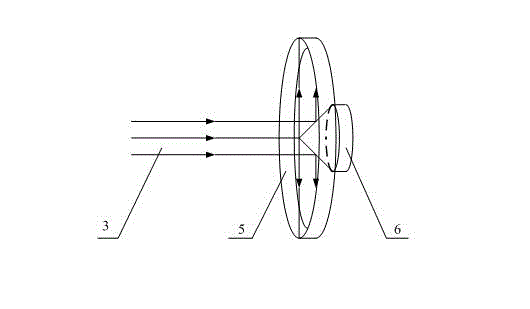

[0045] A laser shot-peening strengthening device for the inner wall of a medium and small-diameter long tube, which includes a laser 1, a beam focusing system 2, a pipe fitting 4, a conical reflector 6 with a vertex angle of 90°, a conical reflector installation axis 7, a pipe fitting protective sleeve 8, a fixed Support 9, pipe fitting fixture 10, working platform 11, guide rail 12, motion control card 13, computer 14 and laser control card 15, pipe fitting 4 is fixed on the working platform 11 by pipe fitting fixture 10, and working platform 11 is connected with guide rail 12; The conical surface of the reflector 6 is coated with a metal reflective film, which is installed on one end of the conical reflector mounting shaft 7 extending into the pipe fitting 4, and the other end of the conical reflector mounting shaft 7 is fixedly installed on the fixed support 9, and the pipe fittings are protected. The sleeve 8 is installed on the end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com